SPRACY2 May 2021 TMUX646

2 PCB Design Guidelines

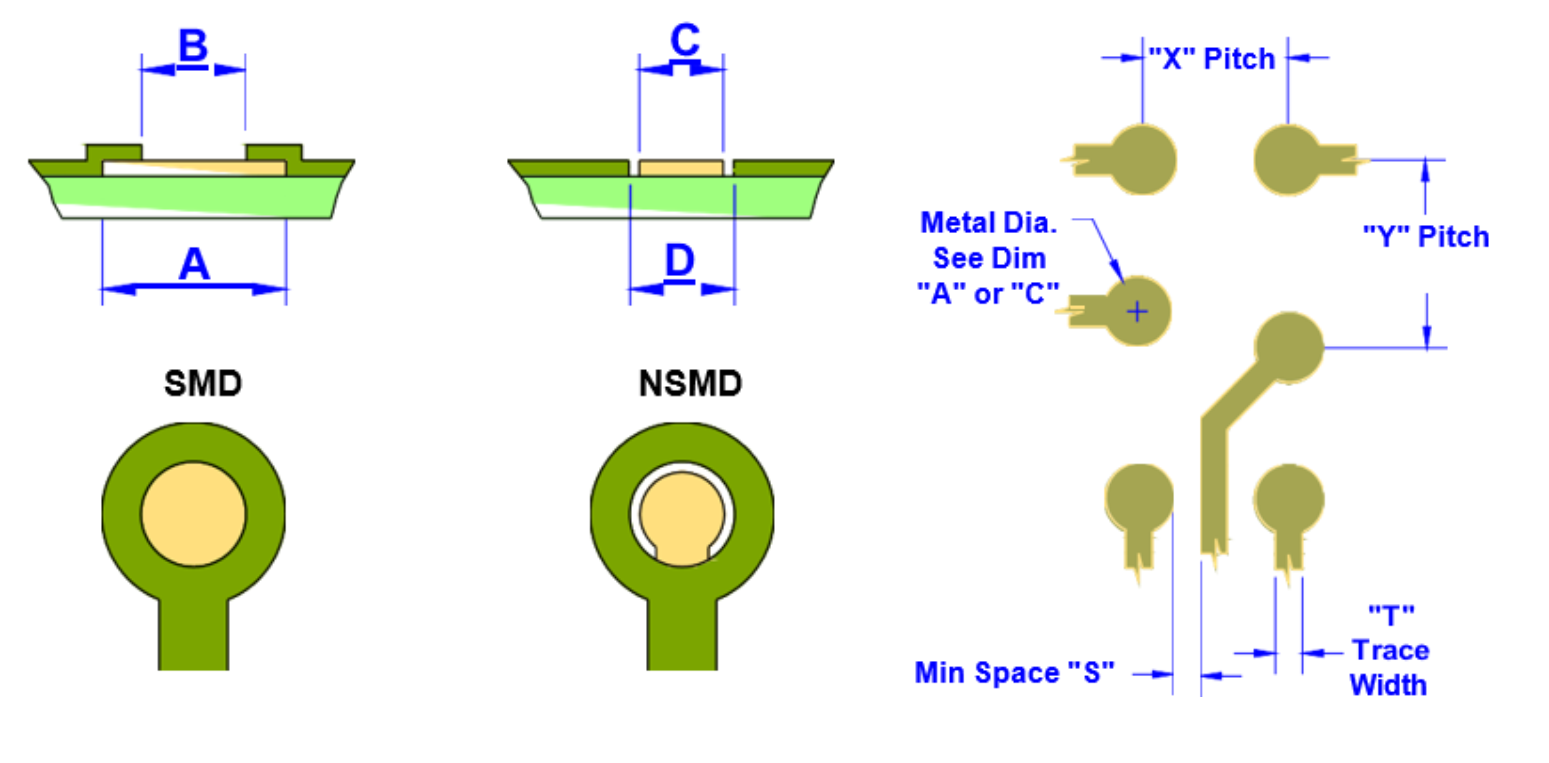

The PCB design guidelines outlined in the Conductor Width/Spacing section of nFBGA Packaging are still applicable to small body nFBGAs. Figure 2-1, Table 2-1 and Table 2-2 outline examples of specific pad, trace, and width dimensions for small body packages.

Figure 2-1 Solder Pad and Trace

Dimensions

Figure 2-1 Solder Pad and Trace

DimensionsTable 2-1 Sample Small Body nFBGA Solder Pad

Details

| Solder Mask Defined Pad (SMD) | Non-Solder Mask Defined Pad (SMD) | |||

|---|---|---|---|---|

| Package Designator | Copper Pad (A) | Solder Mask Opening (B) | Copper Pad (C) | Solder Mask Opening (D) |

| ZWA | 0.35 mm | 0.25 mm | 0.25 mm | 0.35 mm |

| ZEC | 0.30 mm | 0.23 mm | 0.23 mm | 0.30 mm |

Table 2-2 Trace Width Spacing

Examples

| Pitch (mm) | Metal Diameter (“A” or ”C”) | Trace Width/ Spacing (“S” or “T”) |

|

|---|---|---|---|

| SMD pad | 0.40 | 0.35 | 0.05 |

| 0.50 | 0.10 | ||

| NSMD Pad | 0.40 | 0.25 | 0.08 |

| 0.50 | 0.13 |

TI recommends the use of type 3 or finer solder paste when mounting nFBGA. The use of paste offers the following advantages:

- It acts as a flux to aid wetting of the solder ball to the PCB land.

- The adhesive properties of the paste will hold the component in place during reflow.

- Paste contributes to the final volume of solder in the joint, and thus allows this volume to be varied to give an optimum joint.

- Paste selection is normally driven by overall system assembly requirements. In general, the "noclean" compositions are preferred due to the difficulty in cleaning under the mounted components.

TI recommends a pressure safety zone in mounting the nFBGA package. Recommended force should be controlled to 5N maximum for static and 2.5N for impact.