SPRADC9 july 2023 AM62A3 , AM62A7

4.4 Physical Demo Setup

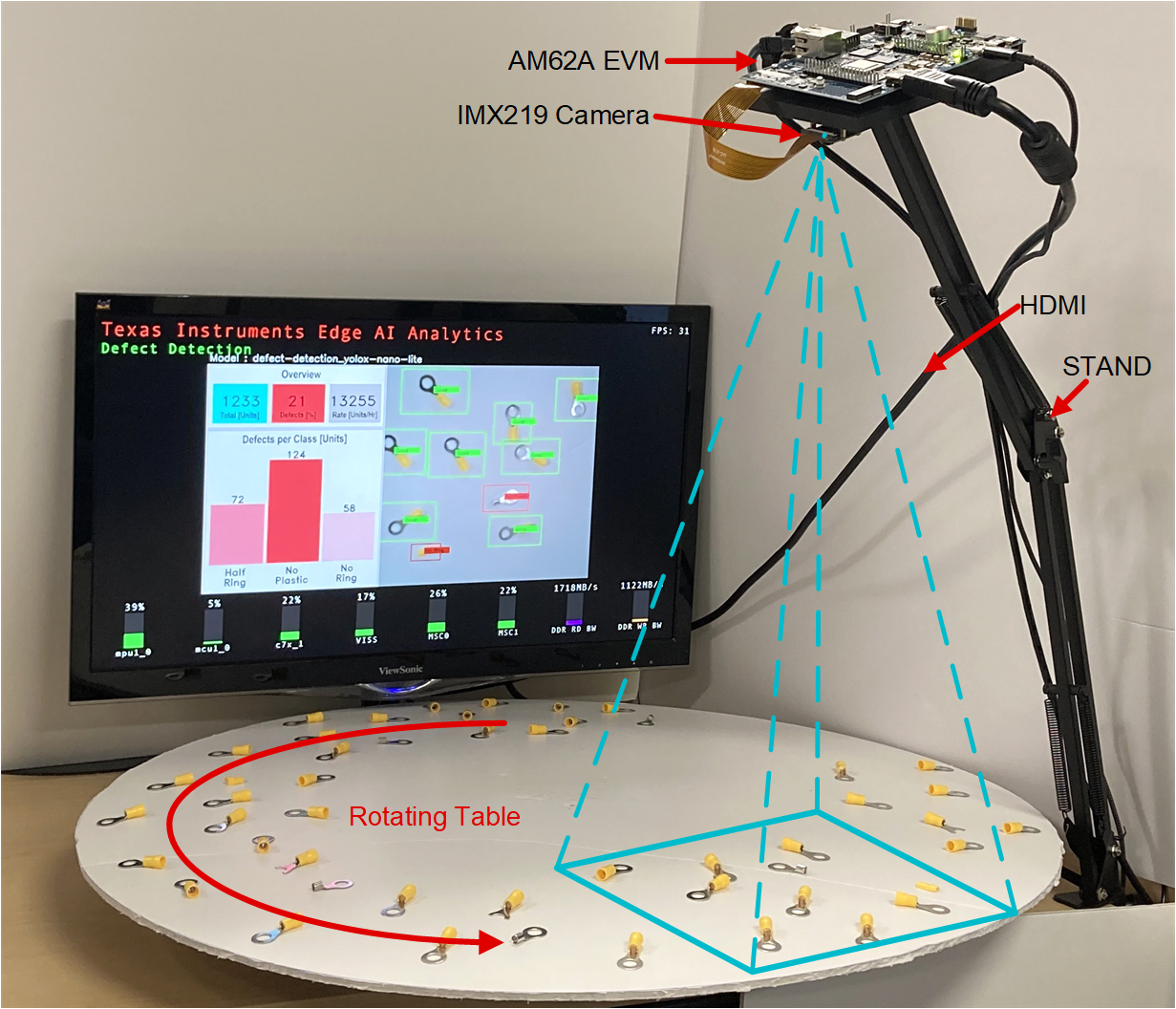

The defect detection application is designed to work on a production line where units are moving on a conveyor belt. For demo purpose, a rotating table is used to emulate the conveyor belt. Figure 4-2 shows the physical setup of the defect detection demo. The camera is positioned at a height to include only a square part of the rotating table in the frame. When the table rotates, the units on it will appear to the camera as if they were placed on a linear conveyor belt. This setup simplifies the demo to eliminate the need to reload the units.

Figure 4-2 Defect Detection Demo Setup

(Only part of the rotating table is within camera frame to emulate a conveyor

belt.)

Figure 4-2 Defect Detection Demo Setup

(Only part of the rotating table is within camera frame to emulate a conveyor

belt.)