SPRUJF4A October 2024 – December 2024

- 1

- Description

- Features

- Applications

- 5

- 1Evaluation Module Overview

- 2Hardware

- 3Motor Control Software

-

4Test Procedure and Results

- 4.1 Build Level 1: CPU and Board Setup

- 4.2 Build Level 2: Open-Loop Check With ADC Feedback

- 4.3 Build Level 3: Closed Current Loop Check

- 4.4 Build Level 4: Full Motor Drive Control

- 4.5 Test Procedure

- 4.6 Performance Data and Results

- 5Hardware Design Files

- 6Additional Information

- 7References

- 8Revision History

2.1.4.2 Single-Shunt Current Sensing

The single-shunt current-sensing technique measures the DC-link bus current, with knowledge of the power FET switching states and reconstructs the three-phase current of the motor. The detailed description of the single shunt technique is described in the Sensorless-FOC for PMSM With Single DC-Link Shunt application note.

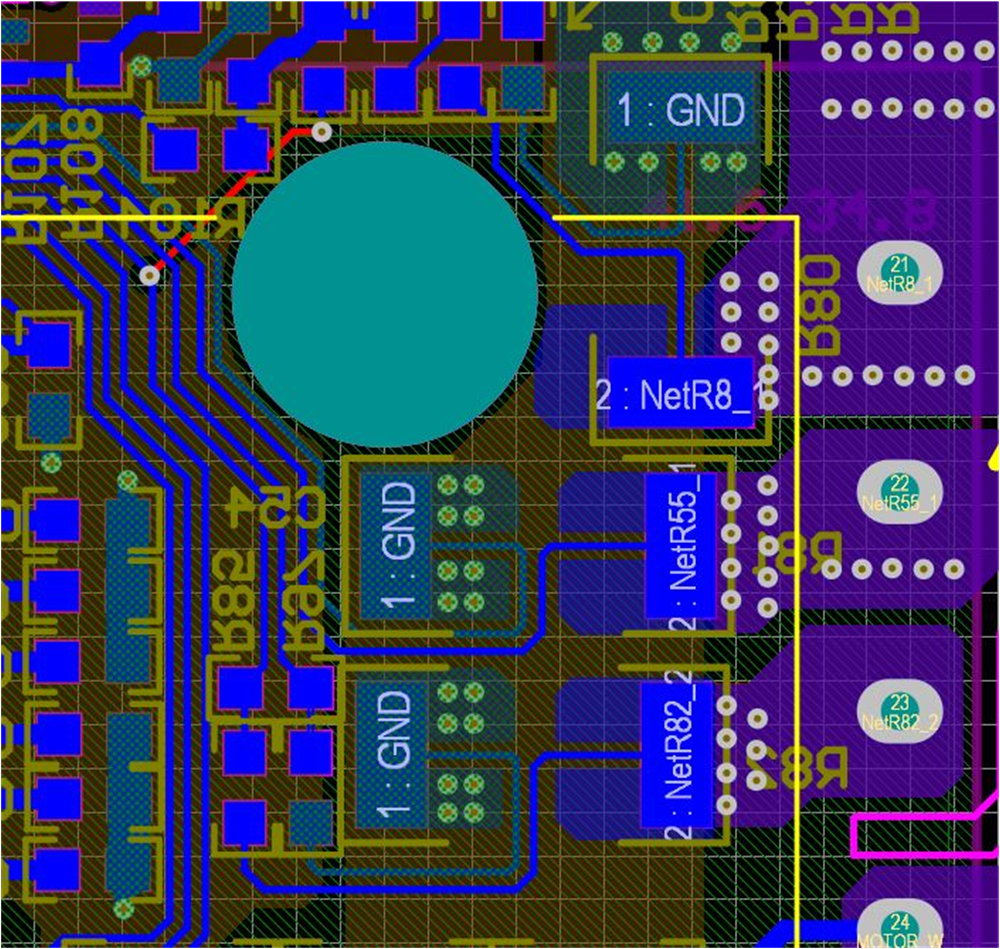

On this reference board, implement the single-shunt current-sensing technique by removing two shunts and shorting the connection of the U, V, W ground of the power module as shown in Figure 2-8.

Figure 2-8 Single-Shunt Current-Sensing

Resistor Configuration

Figure 2-8 Single-Shunt Current-Sensing

Resistor Configuration- On the motherboard, remove current shunt resistors R81, and R82, just keep only shunt resistor R80 to sense the DC-Link current.

- On the TMS320F2800137 daughterboard, remove C23 to increase U3A bandwidth for single-shunt sampling.

- Use a thick wire to connect the NU, NV, and NW pins together.

Figure 2-9 Single-Shunt Current-Sensing Circuit for TMS320F2800137

Figure 2-9 Single-Shunt Current-Sensing Circuit for TMS320F2800137By default, the board has three shunt resistors. Figure 2-10 shows the layout of the shunt resistors. To implement single-shunt resistor sensing, remove R81 and R82 while keeping R80. Solder NU, NV and NW (pin 2 of R80, R81, and R82) together. All three phase currents now flow through only R80.

Figure 2-10 Shunt Resistors Layout

Figure 2-10 Shunt Resistors LayoutThe DC-Link current is a unidirectional signal, so the DC current offset can be set to a minimum or maximum value to improve the ADC sampling range for the DC-Link current as Figure 2-11 shows. On the TMS320F2800137 daughterboard, change R23 from 10 kΩ to 1 kΩ/1% resistor for the reference voltage to have 0.3-V offset for DC current sensing.

Figure 2-11 DC Offset Reference for Single Shunt of TMS320F2800137 Daughterboard

Figure 2-11 DC Offset Reference for Single Shunt of TMS320F2800137 DaughterboardThe transfer function of this current sampling circuit and the calculation for single shunt are the same as for three shunt.