SSZT042 june 2023

Kyle Stone

Among all of the buzzwords to describe the increased electrification of our world, one term should stand out more: current sensing. Few of the innovations you hear about in solar power arrays, electric vehicle (EV) charging stations or robotics would be possible if current-sensing technology wasn’t reliable, accurate and easy to design with.

In this article, I’ll address four key design trends that have emerged from the growth of electrified applications and the current-sensing technologies intended to address them: higher system voltages, increased system protection, telemetry monitoring and reduced form factors. Overall, current sensors are monitoring a vital parameter, current, in an electrical system and this allows for a system to operate as efficiency as possible in a safe range.

Support for Higher System Voltages through Current Sensing

In a DC fast charger, AC power goes into the EV charger from a grid, is converted from AC to DC within the charger, and delivers voltages as high as 920 VDC to the batteries for faster charging. Stepping up to higher voltage levels and keeping similar current levels makes it possible for more power to pass directly into the batteries, making for quicker and more efficient charging.

Figure 1 EV Charger

Figure 1 EV ChargerCurrent sensors help increase system efficiency in EV chargers in and can be used in multiple locations throughout the system. These sensors can be used in the AC line inputs, which monitor current in order to adjust reactive power into the system on the front end. Another is after the power factor control loop and secondary DC/DC, either on the positive or negative node of the system; this configuration monitors for faults.

There is also a location between the primary DC/DC and secondary DC/DC, where current sensing from differential amplifiers be used for flux balancing. In addition, it’s essential to use isolated current sensors like the AMCS1100 or TMCS1100 to protect the system and humans interacting with EV chargers.

Increased System Protection

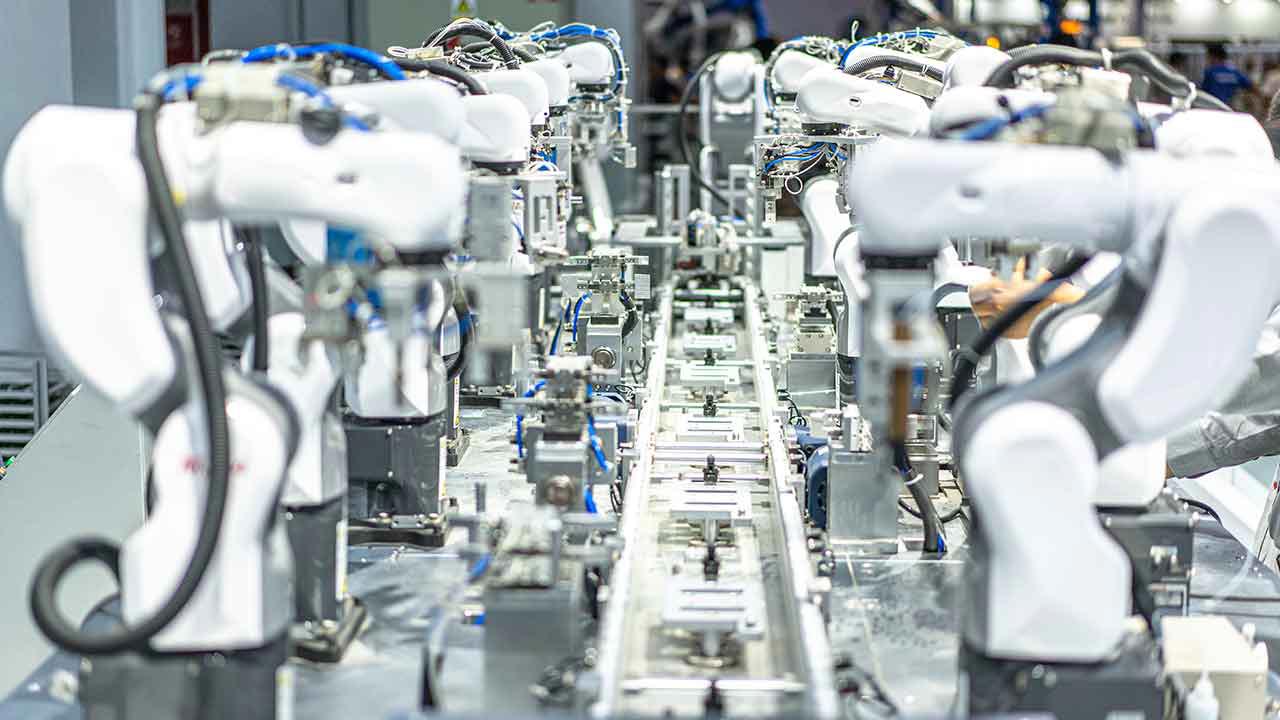

Figure 2 Industrial Robots

Figure 2 Industrial RobotsA current spike may indicate that a load is beyond the robot’s capability, which could potentially damage the content in the system or the physical robotic arm. A current-sensing device with an integrated comparator would see the peak current, perhaps beyond the safe operating area of the system, rush into the electric motors. The INA301 with integrated overcurrent comparator could react as quickly as <1 µS and set an alert, which may cause the system to shut down. This is similar to a point-of-load measurement, where shunt-based sensors like the INA228 and INA226 ultra-precise bidirectional current sense amplifiers can monitor current flow and voltage-levels through a particular node to ensure that the node remains in its safe operating area.

Enabling Telemetry Monitoring

Leveraging a digital power monitor is an appropriate style of device for this use-case, since it takes in both bus voltage and current flow information. Digital power monitor ICs do arithmetic onboard to calculate power, charge and energy and transmits this information (plus the bus voltage and current-flow data) through I2C or serial peripheral interface. Doing the arithmetic on-chip offloads processes from the CPU or microcontroller, so processing resources can be used to handle other tasks more effectively. This is especially important in systems, where the CPU or microprocessor are handled many tasks.

Reduced Form Factors

Leveraging ultra-small ICs or highly featured chips can pave the way to smaller systems. For example, chip packaging options such as a wafer-chip scale package (WCSP) or an INA253 with an integrated shunt enables the designer to shrink the size of their system without sacrificing performance or features.

Conclusion

Additional Resources

- Read the application note, “Design Considerations for Current Sensing in DC EV Charging Applications,” to learn more about current-sensing designs.

- See the application brief, “Current Sensing in Collaborative and Industrial Robotic Arms.”

- Check out the Analog Design Journal article, “System Telemetry: What, Why and How?”