SSZT258 august 2020 AMIC110

Remember when science fiction movies would have a scene showing a fully automated factory managed by artificial intelligence? Such factories exist now!

An autonomous factory relies on real-time communication between individual components such as motion controllers and robots, and this communication must happen in real time. For example, one delayed motion command to a robot controlled by a programmable logic controller (PLC) 100 feet away could result in a defective end product.

Advancements in real-time Ethernet-based communication protocols have solved this problem. These protocols enable a large network of devices inside the factory to communicate with each other in real time, while also providing enough bandwidth to send diagnostic and control data to the cloud.

There’s a catch, however; although many real-time Ethernet protocols facilitate this communication, they aren’t interoperable. The result is that equipment set up to communicate through one real-time Ethernet protocol cannot easily accept another piece of equipment speaking a different protocol – even though both are using an Ethernet connection. So two questions arise: Which protocol should your equipment support, and can you enable multiple protocols?

| Watch our multiprotocol demo | |

|

Learn how to connect a Sitara evaluation module to three common Industrial networks |

The challenges of supporting multiprotocol systems

Three major industrial Ethernet protocols have captured the majority of the industrial market: Profinet, EtherNet/IP and EtherCAT. Picking one of these three is generally a safe bet, but there are benefits and drawbacks to both single and multiprotocol support in a traditional ASIC setup, as listed in Table 1.

| Single protocol | Multiprotocol | |

|---|---|---|

| Benefits | One hardware design for all equipment using that protocol | Captures more market segments using different protocols |

| Challenges with using multiple ASICs | Ability to access only one segment of the market |

|

Reduce your hardware investment with Sitara™ processors

It’s apparent that from a commercial perspective supporting multiple protocols is the right answer, but implementing a multiprotocol solution can become costly and problematic for everyone from engineering to procurement. Figure 1 shows the flow of a company supporting multiple protocols using various ASICs. You can see that there are multiple devices required to make communication modules for each Ethernet solution, resulting in more complexity when creating various stock-keeping units (SKUs).

Figure 1 Traditional flow for multiprotocol support

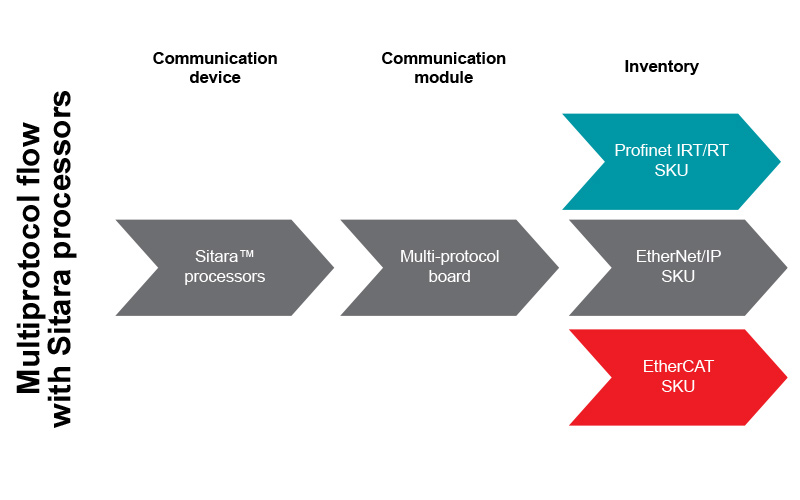

Figure 1 Traditional flow for multiprotocol supportThis flow can deter many factory equipment manufacturers from enabling various protocols on their products. But today, it’s possible to connect to more than protocol one using a multiprotocol-enabled device like a Sitara processor. A Sitara processor such as the AMIC110 enables many protocols with a single design, overcoming the potential challenges of designing a multiprotocol environment. However, Sitara processors offer an alternative way to design factory equipment that supports a variety of industrial Ethernet protocols. The benefits of Sitara devices simplify the flow for creating various SKUs as shown in Figure 2.

Figure 2 Multiprotocol flow with a Sitara processor

Figure 2 Multiprotocol flow with a Sitara processorThe industrial communication subsystem integrated into each processor enables you to create a single hardware design for various SKUs. All you have to do is load a new image onto the processor to connect the board to a new network. This strategic approach can not only lower your system design costs, but can also deliver these advantages:

- The reallocation of inventory from one protocol to another in minutes to meet sudden demand changes.

- The reduction of hardware procurement to a single vendor.

- Drastically reduced warehouse management complexity.

- A single hardware design to meet the needs of multiple markets.

In this video, we’ve created a set of demonstrations to show how to connect to a Profinet, EtherNet/IP or EtherCAT network using a single Sitara AMIC110 industrial communications engine.

Download the software today and run the demos on our evaluation module.

Conclusion

The Sitara AMIC110 processor is an entry-level device that can enable high integration and simplify development and warehouse management flow at a low cost—only $4 USD per unit. Sitara processors enable support for Profinet Isochronous Real Time (IRT), Profinet RT, EtherNet/IP and EtherCAT, with a single industrial-grade solution that has passed conformance for each of these protocols.

Additional resources

- Read more about each protocol in these white papers:

- Learn how to license each protocol stack for production in the application report, “Industrial Communication Protocols Supported on Sitara Processors.”