-

Introduction to the Fundamental Technologies of Power Density

Introduction to the Fundamental Technologies of Power Density

The importance and value of power density in modern power-delivery solutions cannot be overstated.

To better understand the fundamental technologies of high-power-density designs, in this article I’ll examine the four most important aspects of high-power-density solutions:

- Reduced loss generation.

- Optimal topology and control selection.

- Effective heat removal.

- Reducing system volume through mechanical and electrical component integration.

I’ll also demonstrate how partnering with TI, and using advanced technological capabilities and products that support these four aspects, can help improve your efforts to achieve high-power-density figures.

But first, let’s define power density and highlight some important details when comparing solutions based on their power-density figures.

What is power density?

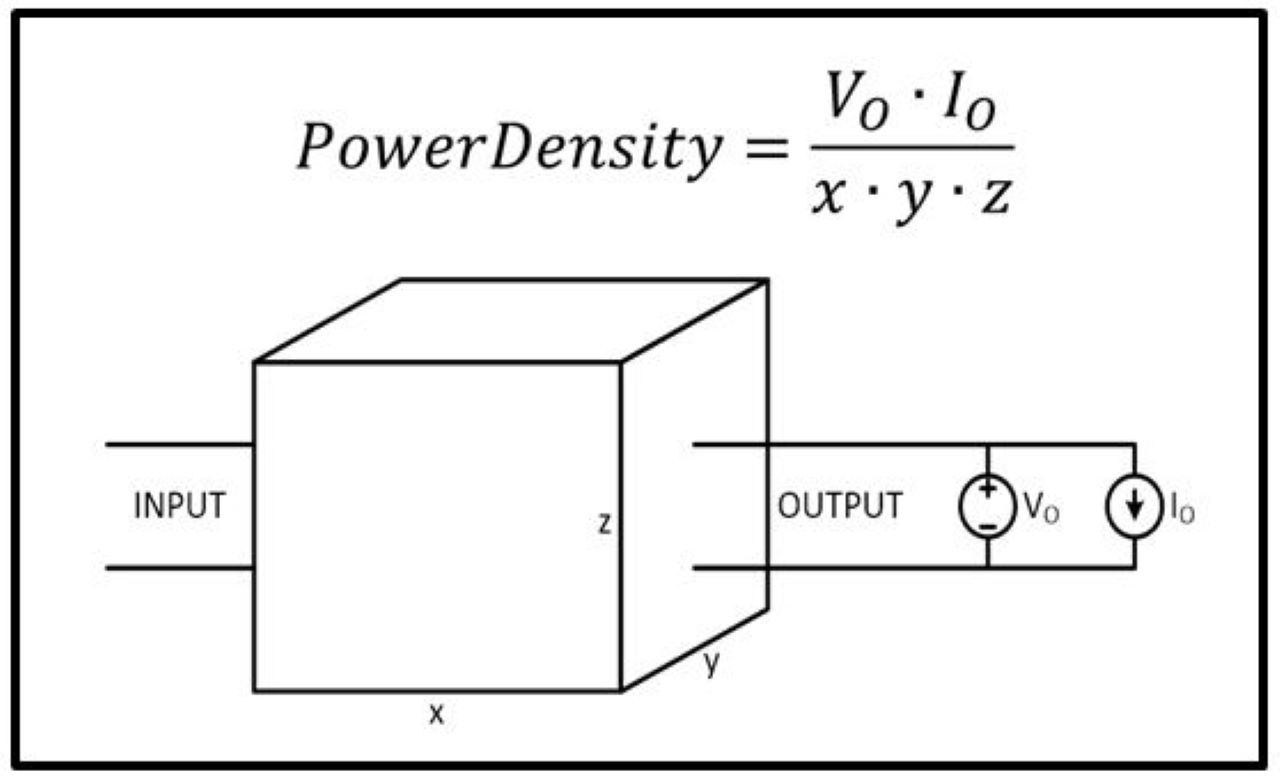

For power-management applications, the definition of power density seems straightforward: it is the rated (or nominal) output power of the converter divided by the volume that the converter occupies as shown in Figure 1.

Figure 1 Calculating power density is

easy, but how nominal power and volume are defined can often lead to

ambiguity.

Figure 1 Calculating power density is

easy, but how nominal power and volume are defined can often lead to

ambiguity.But even this simple definition demands a lot of clarification if you want to compare power supplies, based on their power-densities.

The output power corresponds to the continuous output power that the converter can deliver under worst-case environmental conditions. The relevant power capability may be affected by a combination of ambient temperature, maximum acceptable case temperature, orientation, altitude and expected lifetime.

Similarly, you can define the volume of the power supply in many different ways, depending on the converter’s application and construction. Some of the variables that can significantly impact the volume – and, consequently, the reported power density of the power supplies – are the inclusion or exclusion of electromagnetic interference filters, fans, housing requirements, and input and output energy-storage capacitors, which are often required but not part of many modularized power supplies. Therefore, it is imperative to know and consider these variables when comparing reported power-density data from the literature.

| Learn more about the limitations to increasing power density and how to overcome them. | |

|

Read the white paper now

Read the white paper now

|

History of power density

Let’s have a short historical overview, looking at where the fascination with power density comes from and how this trend began.

Efficiency was a driving force of innovation in power technology since the early days of switched-mode power conversion. Switched-mode power converters made it possible to break the deterministic efficiencies of linear power supplies, which were primarily dependent on input and output voltage ratios and few available topologies.

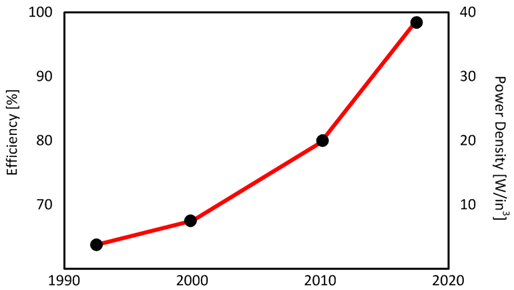

The need to improve efficiency has accelerated significantly since the early 1990s, fueled by personal computing and electronics, telecommunications, and advancements in semiconductor technology. The increased efficiency of the power solutions has been facilitating a continuous progress in power density as well, as depicted in Figure 2.

Figure 2 Efficiency and power density are closely coupled in power-delivery applications.

Figure 2 Efficiency and power density are closely coupled in power-delivery applications.Many waves of energy crises and the consequent emergence of regulatory requirements made efficiency an even more important attribute for power systems, specifically energy conservation and total cost of ownership.

During the last decade, high power density has become recognized as the ultimate pinnacle of power-system engineering.

How to achieve high power density

To better understand the focus on power density, let’s look at what it takes to achieve high power density. The special relationship between efficiency, size and power density is immediately apparent – even for casual observers.

Efficiency is considered the gatekeeper of achieving high power density because it’s imperative to reducing the amount of heat from a device. To take advantage of higher efficiency, a solution’s volume – its size, in other words – must shrink. Achieving both high efficiency and small size at the same time requires a solution that can work efficiently at high operating frequencies. In particular, such a solution should include:

- Reduced switching losses. A switching element that can provide low conduction and low switching losses.

- Topology, control and circuit design. You need the right topology to operate at high switching frequencies. Control methods and innovative circuit implementations are also important, considering that most converter topologies can operate in different modes – such as traditional square-wave pulse-width modulation, zero-voltage or zero-current transition, or full-resonant mode – based on the applied control technique.

- Integration. The scaling effect of the higher operating frequency on passive components can shrink the size of a power converter. But there’s another very important piece of the power-density puzzle – integration – happening in the silicon technology itself through the monolithic incorporation of power and control elements. On the semiconductor device side, designers are using multichip module technology integrating multiple semiconductor dies – and in many cases even passive devices, capacitors and magnetic components. The mechanical and printed circuit board designs of the converters and their enclosures are undoubtedly a crucial factor in achieving high power density.

- Improved thermal performance. TI’s enhanced packaging and advanced leadframe technologies play an important role in minimizing the temperature gradient between the outside cooling surfaces and the actual silicon temperature. These technologies, together with accompanying modeling and optimization capabilities, offer improved thermal performance that can not only enable high-power-density designs but also long-term, reliable operation of TI’s semiconductor devices.

Applying these four fundamental technologies together is the cornerstone of many successfully executed high-power-density designs. Thus, you can view the power density achieved like a report card that grades how well the designer applied the most appropriate semiconductor technology, and whether they selected the right topology, control method, mechanical design, thermal management and integration strategy.

Conclusion

If you truly want to understand why power density is important — beyond viewing it as a universal score to rank technical merit in power engineering — you have to step back and look at how the industry and society as a whole benefit from higher power density.

For example, smaller physical dimensions usually translate to less raw material usage, which could be indicative of lower material cost. Similarly, a smaller size and fewer materials will possibly result in a lower weight, which is an extremely valuable attribute in power systems in the transportation segment that can lead to fuel savings or longer ranges. And finally, with higher power density comes the possibility of miniaturization. Pushing this aspect to its limits has allowed the power-conversion industry to create previously unimaginable new markets.

As these examples show, power density is important given the well-defined economic advantages for the manufacturer, user or operator at the system level that can result in a lower total cost of ownership.

I hope this information, and our related five-part training video series, will inspire you to learn more about our company and technologies, which can enable industry-leading power densities from power-rail voltages below 5 V all the way to 600 V and above, using our advanced silicon technology and high-voltage gallium-nitride power devices.

IMPORTANT NOTICE AND DISCLAIMER

TI PROVIDES TECHNICAL AND RELIABILITY DATA (INCLUDING DATASHEETS), DESIGN RESOURCES (INCLUDING REFERENCE DESIGNS), APPLICATION OR OTHER DESIGN ADVICE, WEB TOOLS, SAFETY INFORMATION, AND OTHER RESOURCES “AS IS” AND WITH ALL FAULTS, AND DISCLAIMS ALL WARRANTIES, EXPRESS AND IMPLIED, INCLUDING WITHOUT LIMITATION ANY IMPLIED WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE OR NON-INFRINGEMENT OF THIRD PARTY INTELLECTUAL PROPERTY RIGHTS.

These resources are intended for skilled developers designing with TI products. You are solely responsible for (1) selecting the appropriate TI products for your application, (2) designing, validating and testing your application, and (3) ensuring your application meets applicable standards, and any other safety, security, or other requirements. These resources are subject to change without notice. TI grants you permission to use these resources only for development of an application that uses the TI products described in the resource. Other reproduction and display of these resources is prohibited. No license is granted to any other TI intellectual property right or to any third party intellectual property right. TI disclaims responsibility for, and you will fully indemnify TI and its representatives against, any claims, damages, costs, losses, and liabilities arising out of your use of these resources.

TI’s products are provided subject to TI’s Terms of Sale (www.ti.com/legal/termsofsale.html) or other applicable terms available either on ti.com or provided in conjunction with such TI products. TI’s provision of these resources does not expand or otherwise alter TI’s applicable warranties or warranty disclaimers for TI products.

Mailing Address: Texas Instruments, Post Office Box 655303, Dallas, Texas 75265

Copyright © 2023, Texas Instruments Incorporated