-

The Need for Current Sensing in Optical Modules for 100G and beyond

The Need for Current Sensing in Optical Modules for 100G and beyond

Manny Soltero

Industry pundits have recently speculated that demand for 100G/400G switches may take off in 2019, prompting optical transceiver module vendors to sample data center switches with high data transmission rates earlier than expected. As data center operators accelerate upgrades in preparation for 5G, demand for 100G/400G transceiver modules will become increasingly robust in the next couple of years. And as transmission data rates in optical modules approach 100 and 400 Gbps, designers must consider the need to monitor and control the components within these modules – such as the photodiodes that receive and transmit optical information.

In this post, I’ll discuss various current-sensing functions in high-bandwidth data communication applications for pluggable optical modules. These pluggable modules remain relatively the same size over time but are expected to pack higher and higher data rates, consume lower power per data rate, operate at lower temperatures, and contain integrated circuits with smaller packages than their predecessors, all while ensuring reliable high-bandwidth communication.

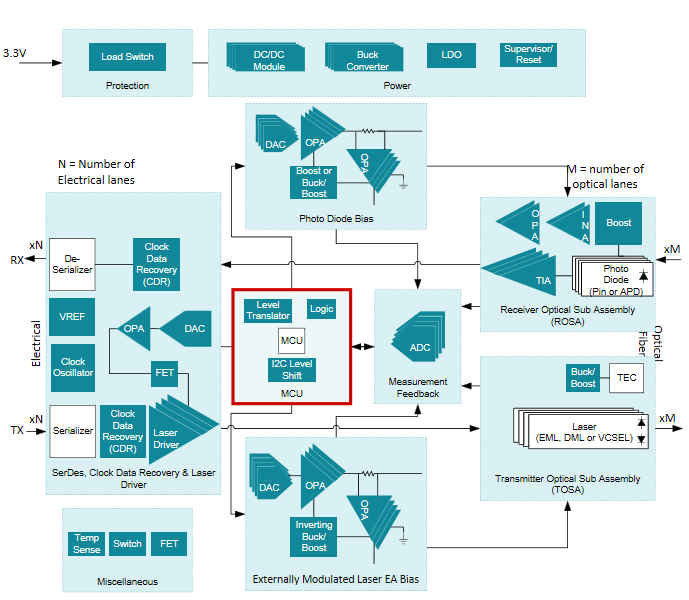

Figure 1 is a block diagram of a typical optical module. Let’s discuss the sections contained within the blue and red boxes within the context of current sensing.

Figure 1 Block Diagram of a Typical

Optical Module

Figure 1 Block Diagram of a Typical

Optical ModuleReceive Path Feedback Control

The blue boxes in Figure 1 highlight the receive path. A precision current-sense measurement within the optical module is necessary for the photodiode control feedback to the microcontroller (MCU) to set the appropriate current based on the link brightness, which in turn sets the gain for the transimpedance amplifier and clock data recovery circuit. In optical modules, PIN diodes or avalanche photodiodes (APDs) are typically used for the receiver optical subassembly. PIN diodes have a wide, undoped intrinsic region between a P-type and an N-type semiconductor region. This wide intrinsic region, which in contrast to an ordinary P-N diode is nonexistent, enables the PIN diode to be perfectly suited for photodetector electronics.

APDs have a very sensitive linear range, forcing module makers to precisely monitor its bias voltage. Another very good reason to monitor the current in an APD is because it will break down quickly at an out-of-range optical power or temperature. Ultimately, a precise current measurement in an APD or PIN diode enables optimal performance and assists in system protection.

Transmit Path Feedback for Laser Modulator and Laser Back Monitor Diode

The bottom red boxes in Figure 1 highlight the transmit path, specifically for biasing the laser diode. Like photodiodes, laser modulators need to be biased to a specific voltage level for maximum linearity to properly modulate the laser light being generated. An externally modulated laser (EML) must be biased with a negative voltage ranging from 0 V to -3.3 V, which makes it tricky for a current-sense amplifier to monitor because it must generate a positive analog voltage that feeds into the analog-to-digital converter (ADC). Figure 2 shows a representation of this circuit. An accurate current measurement of the laser modulator provides feedback to the MCU through an ADC to set the appropriate current based on the module’s temperature.

Figure 2 Measuring Current on a Negative Voltage Bias for EML

Figure 2 Measuring Current on a Negative Voltage Bias for EMLFinally, you will need a precision current measurement at the output of the internal back monitor photodiode (highlighted in the farthest-right red box in Figure 1). Since this back monitor photodiode current is directly proportional to the transmit power of the laser diode itself, it is critical to get a precise current measurement.

To summarize, current-sensing amplifiers are required in various locations within the receive and transmit paths of the optical module. A PIN diode or an APD ranges in current between 10 µA and 10 mA, while the bias for an EML may be in the order of 100 µA and 30 mA. The current through the back monitor photodiode is in a similar range as the APD. Current measurements in these ranges can be very challenging, thus requiring a high-accuracy solution.

The new INA190 and INA191 current-sense amplifiers from Texas Instruments incorporate an extremely low input voltage offset (<±20 µV max) and have a sub-nanoampere (0.5 nA typical) input bias – both necessary for high-accuracy measurements at low current levels. These devices also have the capability to be powered down with an enable pin, operate at a low power current (a quiescent current of 70 µA max) and are available in small packages – the INA191 in a tiny chip-scale package (0.8 mm by 1.2 mm). High accuracy, low-power operation and small packaging make the new INA190 and INA191 a good fit for high-performance 100G and 400G optical modules.

Additional Resources

- Learn more about the INA190 and INA191 and other solutions.

- Download the INA190 data sheet.

- Order the INA190 evaluation module.

- Check out the reference design for optical modules.

- Read this application note: Precision Current Measurements on High-Voltage Power Supply Rails

IMPORTANT NOTICE AND DISCLAIMER

TI PROVIDES TECHNICAL AND RELIABILITY DATA (INCLUDING DATASHEETS), DESIGN RESOURCES (INCLUDING REFERENCE DESIGNS), APPLICATION OR OTHER DESIGN ADVICE, WEB TOOLS, SAFETY INFORMATION, AND OTHER RESOURCES “AS IS” AND WITH ALL FAULTS, AND DISCLAIMS ALL WARRANTIES, EXPRESS AND IMPLIED, INCLUDING WITHOUT LIMITATION ANY IMPLIED WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE OR NON-INFRINGEMENT OF THIRD PARTY INTELLECTUAL PROPERTY RIGHTS.

These resources are intended for skilled developers designing with TI products. You are solely responsible for (1) selecting the appropriate TI products for your application, (2) designing, validating and testing your application, and (3) ensuring your application meets applicable standards, and any other safety, security, or other requirements. These resources are subject to change without notice. TI grants you permission to use these resources only for development of an application that uses the TI products described in the resource. Other reproduction and display of these resources is prohibited. No license is granted to any other TI intellectual property right or to any third party intellectual property right. TI disclaims responsibility for, and you will fully indemnify TI and its representatives against, any claims, damages, costs, losses, and liabilities arising out of your use of these resources.

TI’s products are provided subject to TI’s Terms of Sale (www.ti.com/legal/termsofsale.html) or other applicable terms available either on ti.com or provided in conjunction with such TI products. TI’s provision of these resources does not expand or otherwise alter TI’s applicable warranties or warranty disclaimers for TI products.

Mailing Address: Texas Instruments, Post Office Box 655303, Dallas, Texas 75265

Copyright © 2023, Texas Instruments Incorporated