SSZT541 february 2019

Much confusion exists today with the term “lead-free.” What does it mean? Why is it important? How can you tell if a component or product is lead-free?

A web search of the term produces many hits, including lead-free gasoline, plumbing, jewelry, glass and yes, lead-free electronics. The purpose of this blog post is to clarify what lead-free means and how TI metal-oxide semiconductor field-effect transistor (MOSFET) products comply with lead-free requirements.

Let’s start with a brief history of lead content in electronic components and assemblies. For many years, manufacturers used tin-lead solder to attach components to printed circuit boards. Similarly, lead-containing solder is used in the assembly of components like power MOSFETs and multichip modules to attach silicon die to copper leadframes and packages. Eliminating lead is the goal of all MOSFET vendors, but as of today, a leaded solder die attached still provides the best electrical and most reliable and cost-effective solution.

Lead-free Compliance Requirements

Lead is a known hazardous material that can cause detrimental health effects. Growing concern over the disposal of electronics, called e-waste, led to the adoption of the European Union’s (EU) Restriction of Hazardous Substances (RoHS) Directive 2002/95/EC (RoHS 1) in February 2003. RoHS 1, which became effective in July 2006, restricted the use of six hazardous substances, including lead, in the assembly of electronic and electrical equipment. RoHS 2 expanded the list of banned substances and took effect in January 2013.

There are a number of exemptions to RoHS directives, however. A small number of these exemptions are applicable to TI integrated circuits:

- Exemption 7(a): lead in high-melting-temperature-type solders (lead-based alloys containing 85% by weight or more lead).

- Exemption 7(c)-I: electrical and electronic components containing lead in glass or ceramics other than dielectric ceramic in capacitors (such as piezoelectric devices), or in a glass or ceramic matrix compound.

- Exemption 7(c)-IV: lead in lead zirconate titanate-based dielectric ceramic materials for capacitors that are part of integrated circuits or discrete semiconductors.

- Exemption 15: lead in solders to complete a viable electrical connection between semiconductor die and carriers within integrated circuit flip-chip packages.

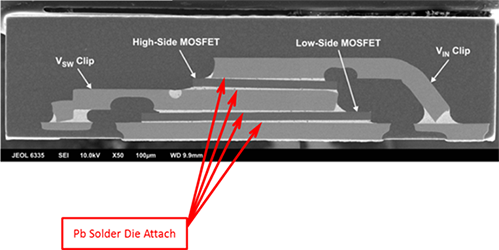

All TI FET devices are lead-free external to the package. Many TI MOSFET products use leaded solder for die attachment to a leadframe and/or copper clip and are subject to Exemption 7(a). Figure 1 shows the stackup of a TI power block (a dual MOSFET device).

Figure 1 Cross Section of TI Power Block

Figure 1 Cross Section of TI Power BlockUnfortunately, there is general lack of industry standards for documenting the lead-free status of semiconductor devices. The available information can be misleading and the designer may not know if the device they have selected is 100% lead-free. The onus is on the designer to check the bill of materials for every device selected.

Where to Go for Lead-free Status of TI MOSFET Products

When reviewing compliance for a specific TI device number, there are several places to find RoHS information.

- Start with the data sheet. TI will include the term “RoHS compliant” in the Features bullet list on the first page of a TI data sheet. In better to understand the device compliance, you should also review the Eco Plan in the Packaging Information section near the end of the data sheet. In that section, TI uses this terminology:

- “RoHS” means semiconductor products that are compliant with current EU RoHS requirements for all 10 RoHS substances, including the requirement that an RoHS substance not exceed 0.1% by weight in homogeneous materials. Where designed to be soldered at high temperatures, RoHS products are suitable for use in specified lead-free processes. TI may reference these types of products as “Pb-Free.”

- “RoHS exempt” means products that contain lead but are compliant with the EU RoHS pursuant to a specific EU RoHS exemption.

- “Green” means that the content of chlorine- and bromine-based flame retardants meets Joint Electron Device Engineering Council JS709C low halogen requirements at a ≤1,000-ppm threshold. Antimony trioxide-based flame retardants must also meet the ≤1,000-ppm threshold requirement.

- Material content search on TI.com. If you need additional details, you can use the material content search function on TI.com for a specific device number.

Table 1 shown below summarizes the lead free status of TI discrete MOSFET and power block products.

| Product category = single MOSFET | |||

|---|---|---|---|

| Package description | Package suffix | 100% lead-free | RoHS exempt |

| Land grid array (LGA) | F3, F4, F5, L | Y | N |

| Wafer-level packaging (WLP) | W, W10, W15, W1015 | Y | N |

| 2-mm-by-2-mm small outline no-lead (SON) | Q2 | Y | N |

| 3-mm-by-3-mm SON | Q3A | Y | N |

| 3-mm-by-3-mm SON | Q3 | N | Y |

| 5-mm-by-6-mm SON | Q5, Q5A, Q5B | N | Y |

| Transistor outline (TO)-220 | KCS | N | Y |

| D2PAK | KTT | N | Y |

| Product category = dual MOSFET | |||

| Package description | Package suffix | 100% lead-free | RoHS exempt |

| LGA | L | Y | N |

| WLP | W15, W1015, W1723 | Y | N |

| S0-8 | ND | Y | N |

| 2-mm-by-2-mm SON | Q2 | Y | N |

| 3-mm-by-3-mm SON | Q3 | N | Y |

| 3-mm-by-3-mm SON | DMS | N | Y |

| Product category = power block | |||

| Package description | Package suffix | 100% lead-free | RoHS exempt |

| 3-mm-by-3-mm SON | Q3D | N | Y |

| 5-mm-by-6-mm SON | Q5D | N | Y |

| 5-mm-by-6-mm dual-cool SON | Q5DC | N | Y |

| PB II | P, N, M | Y | N |

Conclusion

TI strives for compliance with all regulations regarding the use of lead in its MOSFET products. Not all lead-free devices are created equally. Many power MOSFET products from TI and other vendors are lead-free external to the package but use leaded solder internally for die attachment and interconnect. Always check the material content for a device from TI to determine whether it is RoHS compliant and if there are any exemptions.

Additional Resources

- Read TI’s letter regarding the EU RoHS Exemptions expiring in July 2016.