-

Create a Cost-effective Boost Power Supply with True Load-disconnect Functionality

Create a Cost-effective Boost Power Supply with True Load-disconnect Functionality

Charles Wong

The fast-growing consumer electronics market brings opportunities as well as challenges for boost converters. The huge volume drives the market to be very cost-sensitive, so you will need to make trade-offs between solution cost and performance.

The Need for True Load-disconnect Functionality

A boost converter does not have a native mechanism for load disconnection. The rectifier diode or body diode of the synchronous field-effect transistor (FET) passes the battery voltage to the load even when the boost converter is not operating. This leads to continuous battery drainage, even though the leak current may be small.

Many applications require the complete load disconnection and elimination of battery-current leakage when the circuit is not operating. For instance, a boost converter in an electric shaver only needs to operate when it is in use, to boost the battery voltage up for the LED backlight and the motor. Because the electric shaver is off most of the time, disconnecting the loads (the LED backlight and motor in this example) can avoid draining the battery and extend the shaver’s service time between charging or battery replacement.

Obviously, a boost converter with an integrated load-disconnect function is a solution, but the cost of such a device is much higher than a converter without one. This is because a true load disconnect has to be implemented with two high-side power metal-oxide semiconductor field-effect transistors (MOSFETs) in a back-to-back connection, or with a single power MOSFET that can turn off the FET’s body diode. Both implementations can greatly increase the cost of the boost converter integrated circuit (IC). In contrast, a boost converter like the TPS61322xx with an external load disconnect switch offers a cost-effective solution.

True Load-disconnect Configuration Options

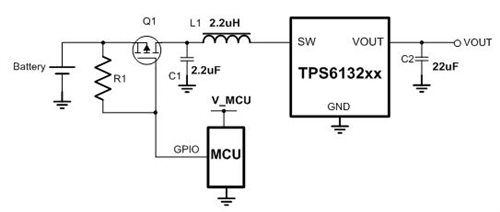

You can implement a load-disconnect function by placing an external switch Q1 in the input power path of the boost converter, as shown in Figure 1. A mechanical switch, p-channel FET, p-channel n-channel p-channel (PNP) transistor, n-channel FET or n-channel p-channel n-channel (NPN) transistor can serve as the disconnect switch.

A popular choice is a mechanical switch, which doesn’t require any extra control logic circuit but loses the ability to be controlled by the system microcontroller (MCU). Solid-state semiconductor devices are more controllable and robust, though. P-channel or n-channel FETs are usually preferable to PNP or NPN transistors because the latter two consume continuous base current to drive.

Between the n-channel FET and p-channel PFET, the RDS(on) of the n-channel FET is less than half the p-channel FET for the same size, and cheaper as well. However, it is challenging to design the printed circuit board (PCB) layout for an n-channel FET because you have to use it to break the ground path. Pay careful attention to the ground routing in these systems. Some applications prohibit the interruption of ground routing, because the broken ground leaves the load circuit energized, which can be a big risk.

Figure 1 Load disconnection by mechanical switch

Figure 1 Load disconnection by mechanical switchAnother popular solution is to use a p-channel FET on the high side of the power path, which doesn’t interrupt the system ground routing. Figure 2 shows a circuit configuration when the supply voltage of the MCU is higher than the battery voltage, and where the MCU directly controls main switch Q1. If the MCU’s supply voltage is lower than the battery voltage, the general-purpose input/output (GPIO) voltage will not be high enough to turn off Q1 successfully. The solution is to use the configuration shown in Figure 3, where introducing a small n-channel FET or NPN transistor (Q2) helps control Q1.

Figure 2 Load disconnection by p-channel FET, V_MCU > VBattery

Figure 2 Load disconnection by p-channel FET, V_MCU > VBattery Figure 3 Load Disconnection by P-channel FET, V_MCU < vBattery

Figure 3 Load Disconnection by P-channel FET, V_MCU < vBatteryIf the ground routing is not a concern, an n-channel FET or NPN transistor can fulfill the load-disconnect function, as shown in Figure 4. This approach is simpler than the p-channel FET configuration, and the MCU controls Q1 directly.

Figure 4 Load Disconnection by N-channel FET

Figure 4 Load Disconnection by N-channel FETSwitch Considerations

It is very important to select a suitable load-disconnect switch. Unlike the MOSFETs of DC/DC converters, the load-disconnect switch is either on or off without frequent switching. Therefore, the gate charge Qg and the parasitic capacitances of the disconnect switch are not a main concern in component selection. Do pay attention to two things, however:

- The rated voltage of the switch should be higher than the battery voltage.

- Assess the RDS(on) of Q1 by allowing about 1% total solution efficiency loss under the maximum load. Use Equations (1) and (2) to calculate the power loss of the disconnect switch:

where IINRMS is the root-mean-square (RMS) value of the input current and RDS(on) is the on-resistance of the switch.

As an example, selecting an MOSFET with an RDS(on) < 25mΩ for 3V-to-5V conversion under a 500mA load causes about 1% loss in overall efficiency. The gate threshold should be less than the minimum battery voltage in order to guarantee operation in the entire range of the battery voltage. Q1 should support in-rush current during startup, during which the battery will charge both the input and output capacitors, and there are not many current-limit factors except for the RDS(on) of Q1 and the boost converter’s internal synchronous FET. This in-rush current is not only related to the slew rate of Q1’s gate voltage, but also affected by the input and output capacitors.

Test Results

I conducted a test with the TPS613222ADBVR, a fixed 5.0-V output voltage boost converter. The conditions were VIN = 1.8V, 2.7V, 3.6V, 4.2V, L = 2.2µH.

As Figure 5, Figure 6 and Figure 7 show, the efficiency differences are very small between the circuit with and without a load-disconnect switch. The worst case is at a heavy load under a low VIN condition, because if VIN < 1.8V, Q1 will not have an adequate gate voltage to fully drive the FET. The RDS(on) will increase and hurt the efficiency.

Figure 5 TPS613222A Efficiency without a Load-disconnect Switch

Figure 5 TPS613222A Efficiency without a Load-disconnect Switch Figure 6 TPS613222A Efficiency with N-channel FET Disconnect Switch (FDN337N, RDS(on) = 82mΩ at vGS = 2.5V)

Figure 6 TPS613222A Efficiency with N-channel FET Disconnect Switch (FDN337N, RDS(on) = 82mΩ at vGS = 2.5V) Figure 7 TPS613222A Efficiency with P-channel FET Disconnect Switch (FDN306P, RDS(on) = 50mΩ at vGS = -2.5V)

Figure 7 TPS613222A Efficiency with P-channel FET Disconnect Switch (FDN306P, RDS(on) = 50mΩ at vGS = -2.5V)Conclusion

A device like the TPS613222A provides a cost-effective solution to applications requiring a true load-disconnect function. You can decide to add the appropriate type of switch according to your end-application requirements. True load disconnection is easy to achieve and the total cost can still remain very competitive. For further information, read the blog post, “How to Select a MOSFET – Load Switching.”

IMPORTANT NOTICE AND DISCLAIMER

TI PROVIDES TECHNICAL AND RELIABILITY DATA (INCLUDING DATASHEETS), DESIGN RESOURCES (INCLUDING REFERENCE DESIGNS), APPLICATION OR OTHER DESIGN ADVICE, WEB TOOLS, SAFETY INFORMATION, AND OTHER RESOURCES “AS IS” AND WITH ALL FAULTS, AND DISCLAIMS ALL WARRANTIES, EXPRESS AND IMPLIED, INCLUDING WITHOUT LIMITATION ANY IMPLIED WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE OR NON-INFRINGEMENT OF THIRD PARTY INTELLECTUAL PROPERTY RIGHTS.

These resources are intended for skilled developers designing with TI products. You are solely responsible for (1) selecting the appropriate TI products for your application, (2) designing, validating and testing your application, and (3) ensuring your application meets applicable standards, and any other safety, security, or other requirements. These resources are subject to change without notice. TI grants you permission to use these resources only for development of an application that uses the TI products described in the resource. Other reproduction and display of these resources is prohibited. No license is granted to any other TI intellectual property right or to any third party intellectual property right. TI disclaims responsibility for, and you will fully indemnify TI and its representatives against, any claims, damages, costs, losses, and liabilities arising out of your use of these resources.

TI’s products are provided subject to TI’s Terms of Sale (www.ti.com/legal/termsofsale.html) or other applicable terms available either on ti.com or provided in conjunction with such TI products. TI’s provision of these resources does not expand or otherwise alter TI’s applicable warranties or warranty disclaimers for TI products.

Mailing Address: Texas Instruments, Post Office Box 655303, Dallas, Texas 75265

Copyright © 2023, Texas Instruments Incorporated