SSZT786 february 2018

Anyone who uses a battery-powered product or device can appreciate the importance of an accurate battery-capacity indicator. It can be very frustrating to have your device suddenly die without any warning.

Traditionally, the simplest method of indicating battery capacity was to measure the battery voltage with an analog comparator and generate a simple low-battery warning below a predetermined threshold. In products that already have a general-purpose microcontroller (MCU), an analog-to-digital converter (ADC) can make a more accurate (digital) voltage reading, compare that reading to a set of predefined levels, and generate a more sophisticated battery-level indicator.

But if you look at the voltage profile of an actual battery in an application with variable load conditions, you will soon learn that a simple voltage-based reading can be very misleading. Assume that a single-series cell-powered system needs to be alerted when the battery voltage is 3.7V, which is based on an open circuit voltage (OCV) of about a 15% state of charge (where 0% is empty and 100% is full). The challenge is that battery voltage may cross 3.7V several times before settling. The system may alert the end user too early and shorten the run time or issue an alert too late and allow the system to crash, potentially even damaging the hardware.

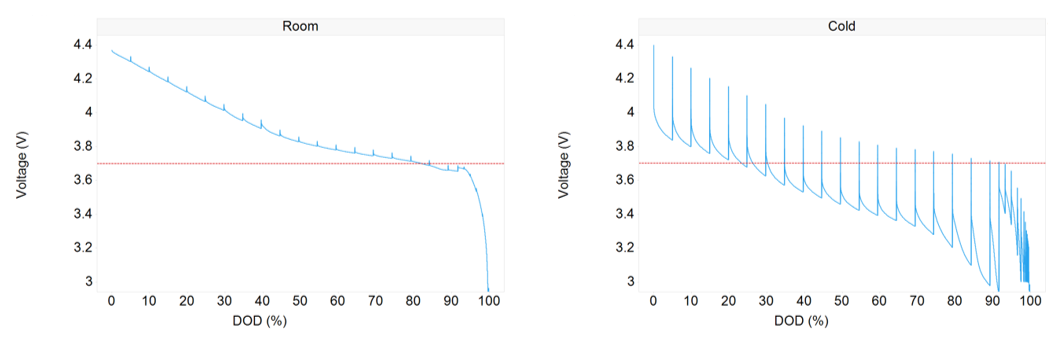

Figure 1 is an example of the same battery responding to dynamic loads at different temperatures. Using a lower current at cold temperatures helps drain out all of the battery’s capacity. The depth of discharge (DOD) (DOD = 1 – true state of charge) normalizes the X axis. The voltage responses appear to be two different animals!

Figure 1 Battery-voltage Response to Dynamic Loads at Different Temperatures

Figure 1 Battery-voltage Response to Dynamic Loads at Different TemperaturesAging is another concern. Once the present full capacity of the battery is below 80% of its original full capacity due to aging, it’s going to spiral down to its end-of-life state very quickly. For an aged battery, a voltage = 3.7V may indicate almost no remaining capacity.

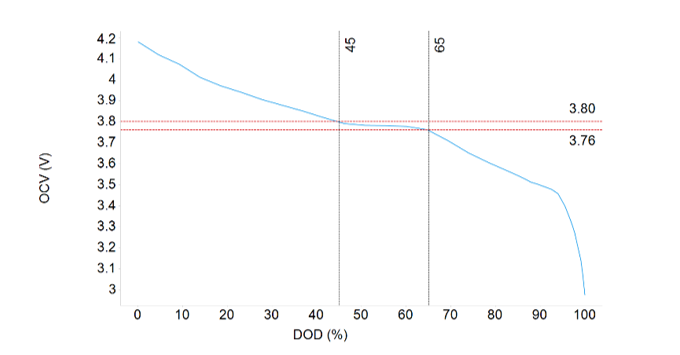

In many cases, a generic MCU’s ADC accuracy is typically not good enough for an accurate state-of-charge calculation. For some batteries, 1mV error converts to a 1% state-of-charge error. Figure 2 is an example where ±20mV accuracy means a 20% state-of-charge error in the flat region, assuming that you need OCV.

Figure 2 DOD Percent Error Caused by OCV Reading Error

Figure 2 DOD Percent Error Caused by OCV Reading ErrorFurthermore, the general-purpose MCU in a system may have many functional blocks and numerous other tasks going on in parallel. It may not be the most power-efficient solution or the most accurate battery-level indicator. But by adding a small external application-specific fuel-gauge device, you can get a more accurate and power-optimized solution.

If the portable device spends a significant amount of time in an idle/low-power state, the main MCU (which could consume more power than a dedicated gauge device) does not have to wake up and consume power just to check on the battery condition. While it can take the MCU several milliamps to measure and calculate the state of charge, a discrete gauge consumes only a small fraction of what an MCU would have consumed– the average current is 20 to 30µA with sleep mode on. With proper power-management techniques, it can even drop to <2µA.

TI’s discrete gauge hardware is specifically designed for battery management. The gauge device takes accurate measurements with minimum power consumption. However, without a proper battery model and supporting gauge algorithm, the measurements are only a reflection of the present moment. The TI models and gauge algorithm comprehend the electrochemical features of many different kinds of batteries and have been proven in many millions of systems in the field.

In addition, TI discrete gauges provide added functionality such as black-box battery forensics, health indication and smart charge control. An accurate gauge device helps bring power management to another level for an enhanced customer experience.

Last but not least, a percentage prediction adds sophistication and intelligence to the product, and instantly improves the end-user experience.

If you’re trying to find the right fuel gauge to your design, try searching our portfolio of gauges.

Additional Resources

-

If you have questions on designing with fuel gauges, search for support here.

- Explore TI’s battery fuel gauge portfolio, with discrete gauges, protection integrated gauges and battery management units.