SSZT829 january 2018

24V systems are common in commercial trucks, including heavy-duty pickup trucks, as well as military vehicles that require extra power.

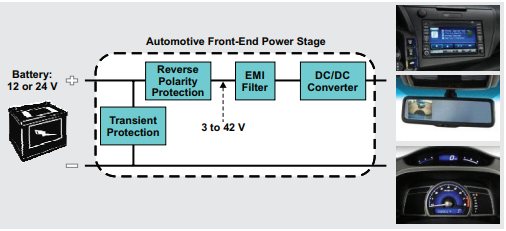

Converting power from 24V batteries to 12V for low-voltage electronics inside a vehicle cockpit necessitates the use of a DC/DC converter with a wide input-voltage range, fast load transient response and complete system protection, as shown in Figure 1.

Figure 1 24V Automotive Battery

System

Figure 1 24V Automotive Battery

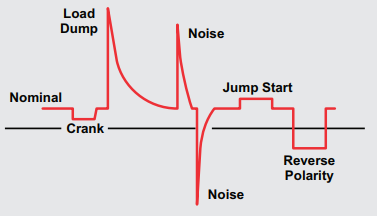

System24V systems (just like 12V systems) can experience wide input-voltage variations as a result of cold-crank and load-dump events, as shown in Figure 2. These peak load-dump transients can be as high as 60V.

Figure 2 24V Battery Input-voltage

Transient Events

Figure 2 24V Battery Input-voltage

Transient EventsA 24V-to-12V buck DC/DC converter has to be able to handle a wide input-voltage variation (up to 60V), provide tight load regulation and system protection, and have strong drivers to enable high conversion efficiency with external metal-oxide semiconductor field-effect transistors (MOSFETs).

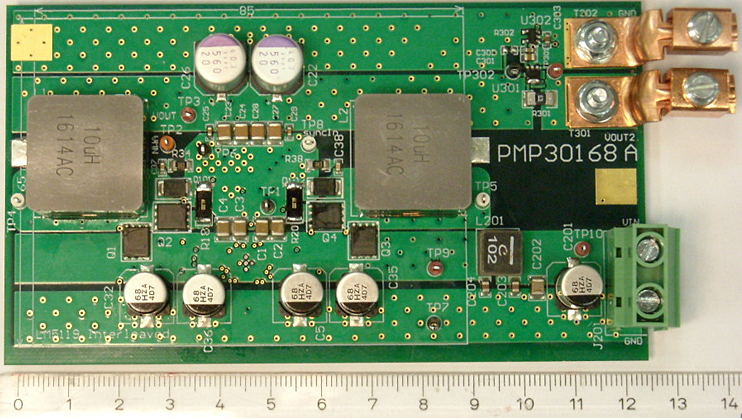

The 280W Automotive Dual-Phase Synchronous Buck Reference Design with 24VDC Input, 12VDC Output showcases a 24V-to-12V automotive battery power-conversion design. The resulting 12V output of the converter is available for various electronics inside the cockpit.

The synchronous buck reference design uses the LM5119-Q1 automotive-qualified two-phase pulse-width modulation (PWM) buck controller and is designed to downconvert 24V to 12V at 20A for a total of 240W of output power. This 240W design is 120mm by 70mm and includes all of the components required for the power supply (Figure 3).

Figure 3 Synchronous Buck Reference

Design 24V to 12V Buck Converter for Automotive Batteries

Figure 3 Synchronous Buck Reference

Design 24V to 12V Buck Converter for Automotive BatteriesThe reference design will support cranking down to 18V and load-dump transients (input voltage overshoot) to 58V.

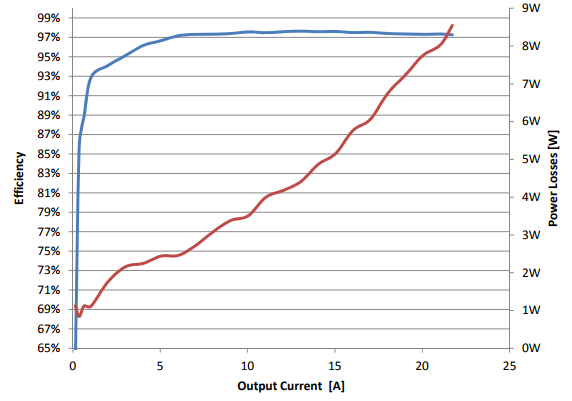

Efficiency is >97% from 6A to 20A with a power loss less than 9W, as shown in Figure 4.

Figure 4 Synchronous Buck Reference

Design 24V-to-12V Buck Converter Efficiency and Power Loss

Figure 4 Synchronous Buck Reference

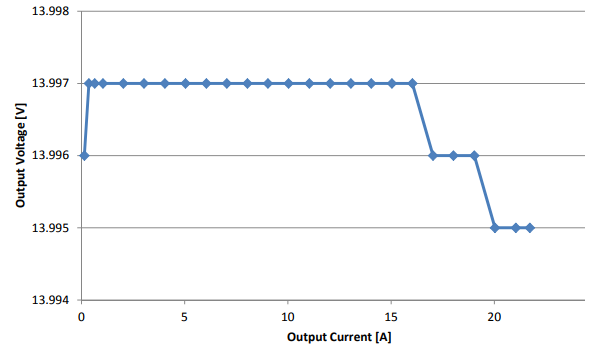

Design 24V-to-12V Buck Converter Efficiency and Power LossAs shown in Figure 5, the load regulation has only 2mV of deviation over the load current range.

Figure 5 Synchronous Buck Reference

Design Load Regulation

Figure 5 Synchronous Buck Reference

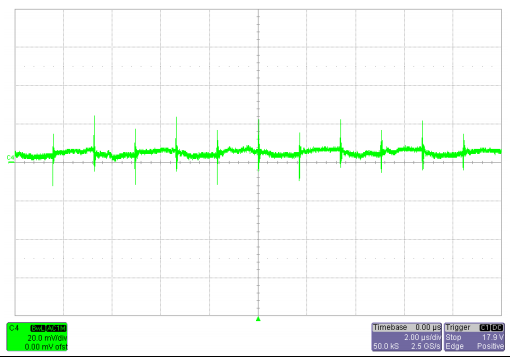

Design Load RegulationOutput ripple voltage is less than 10mVpp, with noise at 20mVpp (Figure 6).

Figure 6 Synchronous Buck Reference

Design Output Voltage Ripple

Figure 6 Synchronous Buck Reference

Design Output Voltage RippleIf you are designing an automotive battery 24V-to-12V buck DC/DC converter, consider this reference design for your toolkit. It comes with all of the technical documents and files to enable a quick implementation so that you and your customers can start steering the wheel.

Additional Resources:

- Read the Analog Applications Journal article, “Designing the front-end DC/DC conversion stage to withstand automotive transients.”

- Check out the automotive applications portal.