-

How Level Shifters Enable the Transition to Low-voltage Processors in Industrial Environments

How Level Shifters Enable the Transition to Low-voltage Processors in Industrial Environments

Atul Patel

Consumer, computing, personal electronics, enterprise networking, automotive and industrial use cases are moving rapidly toward lower-voltage processor and microcontroller technologies. The advantages of lower-voltage processor-based systems – higher levels of energy efficiency, longer battery life, improved thermal performance, reduced production costs and lower cost of ownership – are powerful incentives for system designers. Today, I am focusing on the benefits industrial system designers gain from moving to low voltage processors.

Given that industrial applications areas such as building automation, factory automation and smart grid by nature need to support higher-voltage peripheral devices such as connected sensors, actuators, field buses, motor-drive units and many other components operating at higher-voltage domains, choosing a lower-voltage processor-based design can become especially complicated. The major challenge that industrial system designers face when integrating higher-voltage components with lower-voltage processors is bridging the data interfaces between components that operate at different voltage levels. You cannot simply connect the data and control interfaces of devices on different voltage rails together and then expect them to interoperate.

Industrial system designers resolve voltage-level differences in data and control interfaces by level shifting (also known as level translating) the interfaces to common voltage levels so that the devices can interoperate as expected. System designers have historically used multiple discrete components such as transistors and resistors to implement level-shifting schemes within their applications. However, today’s modern designs are using integrated level-shifting solutions like integrated circuits (ICs), which provide a greater level of flexibility, scalability and robustness when compared to discrete implementations.

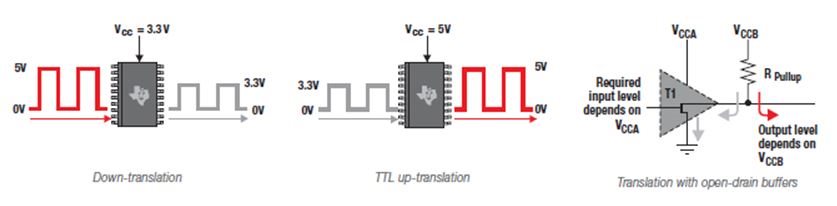

The value of integrated level-shifting solutions becomes very clear as the number of data lines that need to shift increases for a given implementation. For example, level shifting an 8- or 16-bit interface would require 20 to 50 discrete components compared to a single level-shifter IC. In addition, the discrete solutions would require a greater amount of engineering effort to manage component-to-component performance variability, such as a propagation delay over temperature and its associated impact on system timing. The large increase in component count, associated with discrete implementations, also increases the probability of system reliability issues. As industrial systems become more sophisticated, integrated level-shifting solutions are becoming an important component of a design engineer’s toolbox. Figure 1 offers a few examples of integrated level shifting.

Figure 1 Example of Step Down and Step

up Level Translation

Figure 1 Example of Step Down and Step

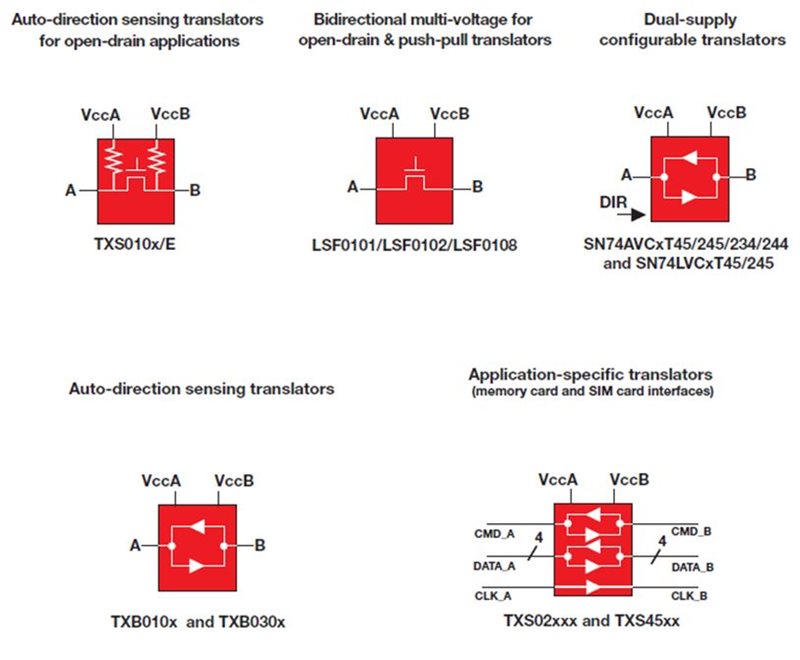

up Level TranslationIntegrated level-shifting solutions are available in a wide array of bit widths, data-rate ranges, current drive capabilities, package options and other application-specific functions. For example, TI’s portfolio of level-shifter devices contains several different types of functions to address almost any application requirement. Common level-shifter types include auto-direction-sensing level translators; bidirectional multi-voltage-level translators; dual-supply direction-controlled push-pull level translators; auto-direction-controlled push-pull level translators; and finally, application-specific level translators. Figure 2 shows some examples of the different level-shifter types.

Figure 2 Example of Different Level

Translator Types

Figure 2 Example of Different Level

Translator TypesIn the next installment of this two-part series, we will explore how to select the appropriate translator solution and rules of thumb for implementing level translators in industrial applications. In the meantime, to learn more about voltage-level translation, log in to leave a comment or visit voltage level translation portal.

Additional Resources

- Download the application note, “Voltage Translation Between 3.3-V, 2.5-V, 1.8-V and 1.5-V Logic Standards.”

- Read the “Voltage Level Translation Guide.”

- Start designing now with a voltage-level translation evaluation module:

- Learn more about low-voltage processors.

IMPORTANT NOTICE AND DISCLAIMER

TI PROVIDES TECHNICAL AND RELIABILITY DATA (INCLUDING DATASHEETS), DESIGN RESOURCES (INCLUDING REFERENCE DESIGNS), APPLICATION OR OTHER DESIGN ADVICE, WEB TOOLS, SAFETY INFORMATION, AND OTHER RESOURCES “AS IS” AND WITH ALL FAULTS, AND DISCLAIMS ALL WARRANTIES, EXPRESS AND IMPLIED, INCLUDING WITHOUT LIMITATION ANY IMPLIED WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE OR NON-INFRINGEMENT OF THIRD PARTY INTELLECTUAL PROPERTY RIGHTS.

These resources are intended for skilled developers designing with TI products. You are solely responsible for (1) selecting the appropriate TI products for your application, (2) designing, validating and testing your application, and (3) ensuring your application meets applicable standards, and any other safety, security, or other requirements. These resources are subject to change without notice. TI grants you permission to use these resources only for development of an application that uses the TI products described in the resource. Other reproduction and display of these resources is prohibited. No license is granted to any other TI intellectual property right or to any third party intellectual property right. TI disclaims responsibility for, and you will fully indemnify TI and its representatives against, any claims, damages, costs, losses, and liabilities arising out of your use of these resources.

TI’s products are provided subject to TI’s Terms of Sale (www.ti.com/legal/termsofsale.html) or other applicable terms available either on ti.com or provided in conjunction with such TI products. TI’s provision of these resources does not expand or otherwise alter TI’s applicable warranties or warranty disclaimers for TI products.

Mailing Address: Texas Instruments, Post Office Box 655303, Dallas, Texas 75265

Copyright © 2023, Texas Instruments Incorporated