-

Advantages of Leaded Packages in Robust Industrial Designs

Advantages of Leaded Packages in Robust Industrial Designs

Michael DeSando

This article was co-authored by Harrison Overturf and updated in August 2020.

When designing industrial applications, engineers want to work with robust and reliable packages that can withstand harsh environments as well as extreme electrical conditions. With the evolution and miniaturization of the integrated circuit (IC), packages have also evolved and become smaller. While smaller packages lead to smaller total solutions, they come with some disadvantages, making it harder for engineers to quickly and easily rework boards that fail in the field, or extract heat from the system - both important considerations in industrial design.

Integrated circuits come in a variety of shapes and sizes, and can be physically connected into a given circuit in a number of ways. In this post, I’ll discuss the robustness of various packages such as the TO-263, TO-220, and the SOIC, specifically with regards to TI’s LM2576, LM2596, LM2676, and LMR36510 SIMPLE SWITCHER® step-down regulators. These packages provide an easy assembly, along with superior thermal characteristics.

Ease of Use

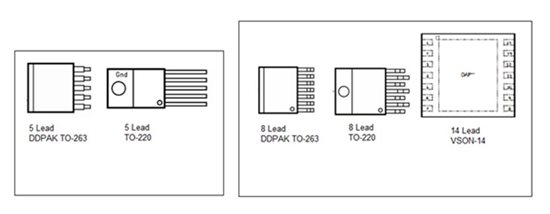

LM2576, LM2596, and LM2676 nonsynchronous buck converters require only input and output capacitors, a power inductor, and a catch diode for a complete circuit application, which makes each design very simple, with low part count and low cost. Figure 1 illustrates the products with each package option.

Figure 1 LM2576, LM2596, and LM2676 Regulators

Figure 1 LM2576, LM2596, and LM2676 RegulatorsThe long leads of the DDPAK and TO packages allow for easy soldering during assembly compared to other packages that have very short leads or leads under the package. The TO-220 packages enable engineers to either bolt the device to the PCB, which can be useful if an application requires extreme mechanical stability due to quick, sudden changes in direction or movement, and/or bolt an additional heat sink on the device, if an application requires maximum heat dissipation.

Figure 2 HSOIC-8 Package Used for LMR36510 and LMR33610 Regulators

Figure 2 HSOIC-8 Package Used for LMR36510 and LMR33610 RegulatorsThe SOIC-8 package of the LMR36510 and LMR33610 also offers improved resistance to mechanical strain. The helps to absorb physical flex on a PCB which makes the end equipment more resilient. The leads facilitate quick visual inspection of a PCB which can be helpful when debugging in the field. TI’s LMR36510 and LMR33610 are a scalable device family meaning that every device in the family shares the same pin-out, allowing engineers to use the same PCB layout for multiple designs and save time.

Thermal Performance

LM2576, LM2596 and LM2676's package types offer excellent heat-dissipating characteristics. In nearly all applications, a heat sink is not required; saving space and reducing cost and part count. For both the TO-263 and TO-220 packages, the junction-to-case temperature increases 2°C/W. The junction-to-case temperature increases 30°C/W for switching-regulator devices with smaller TSSOPs.

Better thermal resistance means that the part won’t heat up as much during operation, which makes it (and thus the overall system) more stable and reliable. As part heats up, the electrical characteristics can vary depending on how hot the part gets. At higher temperatures, efficiency and regulation can worsen. If a part reaches its upper temperature threshold, it can become damaged, causing the system to fail.

The applications engineering team at TI tested the thermal performance of the LM2596 buck converter against pin-to-pin compatible parts from various manufacturers. These parts will be referred to as Regulator W, X, Y, Z. Table 1 below shows a summary of the measured temperatures of the IC as well as the catch diode during short circuit tests. All tests were performed using the TO-263 package on PCBs with the same layout and external components.

| IC Temperature (°C) | Diode Temperature (°C) | |

| TI Simple Switcher LM2596 | 38.1 | 69.9 |

| Regulator W | 80.9 | 110.0 |

| Regulator X | 59.2 | 85.5 |

| Regulator Y | 45.7 | 88.4 |

| Regulator Z | 57.9 | 78.6 |

Conclusion

For industrial designs where excellent thermal performance is of utmost importance, consider using TI’s LM2576, LM2596, and LM2676 regulators in robust packages which offer reduced part count and a proven track record of performance. The ease of use and scalability of the LMR36510 and LMR33610 can help simplify your designs and save time.

Additional Resources:

- Learn more about thermal performance in this training video series, "Thermal Performance – It Matters."

- Read these technical articles:

- Find all TI Packages here.

IMPORTANT NOTICE AND DISCLAIMER

TI PROVIDES TECHNICAL AND RELIABILITY DATA (INCLUDING DATASHEETS), DESIGN RESOURCES (INCLUDING REFERENCE DESIGNS), APPLICATION OR OTHER DESIGN ADVICE, WEB TOOLS, SAFETY INFORMATION, AND OTHER RESOURCES “AS IS” AND WITH ALL FAULTS, AND DISCLAIMS ALL WARRANTIES, EXPRESS AND IMPLIED, INCLUDING WITHOUT LIMITATION ANY IMPLIED WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE OR NON-INFRINGEMENT OF THIRD PARTY INTELLECTUAL PROPERTY RIGHTS.

These resources are intended for skilled developers designing with TI products. You are solely responsible for (1) selecting the appropriate TI products for your application, (2) designing, validating and testing your application, and (3) ensuring your application meets applicable standards, and any other safety, security, or other requirements. These resources are subject to change without notice. TI grants you permission to use these resources only for development of an application that uses the TI products described in the resource. Other reproduction and display of these resources is prohibited. No license is granted to any other TI intellectual property right or to any third party intellectual property right. TI disclaims responsibility for, and you will fully indemnify TI and its representatives against, any claims, damages, costs, losses, and liabilities arising out of your use of these resources.

TI’s products are provided subject to TI’s Terms of Sale (www.ti.com/legal/termsofsale.html) or other applicable terms available either on ti.com or provided in conjunction with such TI products. TI’s provision of these resources does not expand or otherwise alter TI’s applicable warranties or warranty disclaimers for TI products.

Mailing Address: Texas Instruments, Post Office Box 655303, Dallas, Texas 75265

Copyright © 2023, Texas Instruments Incorporated