-

Power Tips: How to Reduce D-CAP Control Output Capacitance

Power Tips: How to Reduce D-CAP Control Output Capacitance

Manjing Xie

When selecting output capacitors for a switching regulator, application requirements such as output ripple or transient response will usually determine how much output capacitance you need. This assumes that you can adjust the compensation network to accommodate a variety of output capacitors. For control architectures without compensation such as D-CAP™ control, the output capacitors you select should guarantee system stability as well.

Here is an example with the following application requirements:

- VIN = 10V.

- VOUT = 3.3V.

- Iout = 20A.

- Fsw = 400KHz.

- Output ripple = ± 0.5%.

- Output current step = 5A with di/dt of 10A/µsec.

- Allowable transient overshoot and undershoot = ± 3%, including output ripple.

I selected a D-CAP regulator, TPS53355 and an inductor of 1.0µH. The application requires all-ceramic output capacitors. To meet the ± 0.5% output-ripple requirement, I need 30µF output capacitance. To meet the 3% transient-response requirement, I need 146µF output capacitance, assuming that the cross-over is at one-sixth the switching frequency. With a maximum allowable ripple injection of 50mV, using Equation 11 in the TPS53355 data sheet, I calculated that I need 240µF output capacitance for stability. That means that I need an additional 94µF capacitance more for stability than for transient response.

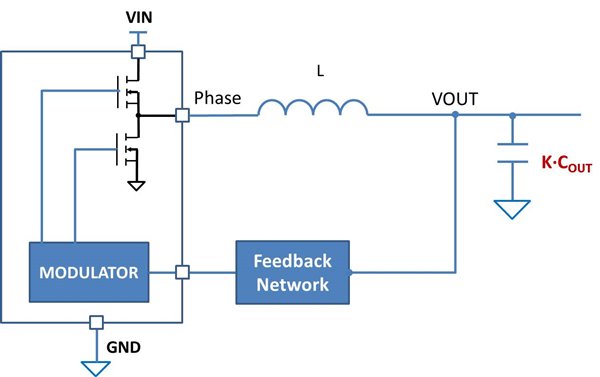

How can I achieve stability without an additional 94µF capacitance? I have a simple solution. The idea is to create an equivalent output capacitance of 240 µF for the feedback system with the capacitors to meet transient response requirement. To do this, I added an AC attenuator stage to the feedback path, as shown in Figure 1.

Figure 1 Buck converter block diagram

with AC attenuator stage

Figure 1 Buck converter block diagram

with AC attenuator stageSystem cross-over frequency is usually one-sixth to one-fourth the switching frequency, which is much higher than the double-pole frequency of the buck converter. The AC attenuator shown in Figure 1 is designed to be effective at frequencies higher than the double-pole frequency as well. Subsequent discussion is only fore frequencies much higher than the double-pole frequency.

If the attenuation of the AC attenuator is K, the system shown in Figure 2 should have similar loop gain as the system shown in Figure 1 at frequencies higher than one-fourth of the switching frequency.

Figure 2 Equivalent block diagram with

K times output capacitance

Figure 2 Equivalent block diagram with

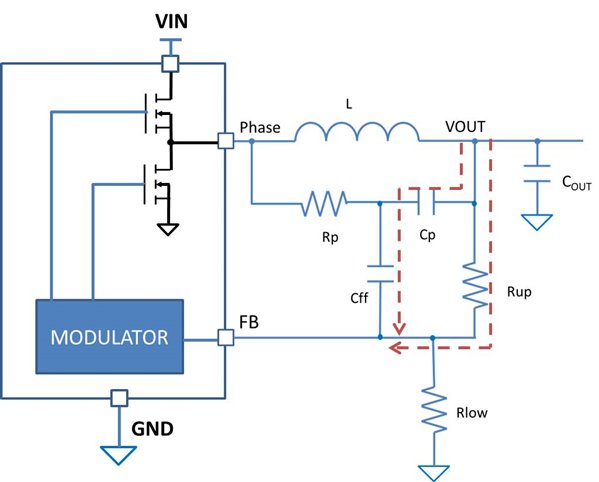

K times output capacitanceHow did I insert the AC attenuator? Let’s examine the original feedback network of a D-CAP regulator, as shown in Figure 3.

Figure 3 Block diagram of a D-CAP

regulator with a DCR injection circuit

Figure 3 Block diagram of a D-CAP

regulator with a DCR injection circuitCp is usually of value much greater than Cff and can be considered shorted at frequencies higher than cross-over frequency. The pull-up capacitors, Cff and resistor, Rup forms a zero. The divider gain increases to 1 at high frequencies as shown in Figure 4. To attenuate the divider gain, I added a pull-down capacitor, Cpp, from the FB pin to GND. Figure 4 shows the effect of a 1nF Cpp on the feedback gain. The feedback network gain is reduced by 5dB at one-fourth the switching frequency. This is equivalent to an attenuation of 1.8.

Figure 4 Bode plots of transfer

functions from VOUT to FB with and without Cpp

Figure 4 Bode plots of transfer

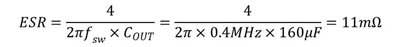

functions from VOUT to FB with and without CppIf a 160µF output capacitor is used, the attenuator creates an equivalent capacitance of 288µF for stability. Since the attenuation is applied to both the output capacitance and ripple injection by Rp and Cp at the same time, the original stability criteria remain effective. Referring to Equation 7 in the TPS53355 data sheet, an equivalent series resistance, ESR of 11mΩ is required for stability.

Figure 5 Equation 1

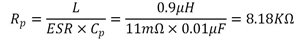

Figure 5 Equation 1The ripple across Cp should be of amplitude similar to that across the ESR as calculated above. Thus, I calculated Rp as:

Figure 6 Equation 2

Figure 6 Equation 2The Inductance rolls off to 0.9µH at full load. I selected a standard resistor value of 7.87KΩ for Rp.

To verify my proposed solution, I modified the High Power Density Buck Converter with Integrated FET DCAP Regulator TI Design reference design to meet the application requirements. Here are the key circuit parameters:

- L = 1.0µH.

- Total output capacitance = 161µF.

- For the DCR injection

circuit:

- Rp = 7.87kΩ and Cp = 0.01µF.

- For the resistor

divider network:

- Rlow = 3.24kΩ, Rup = 14kΩ, Cff = 1nF and Cpp = 1nF.

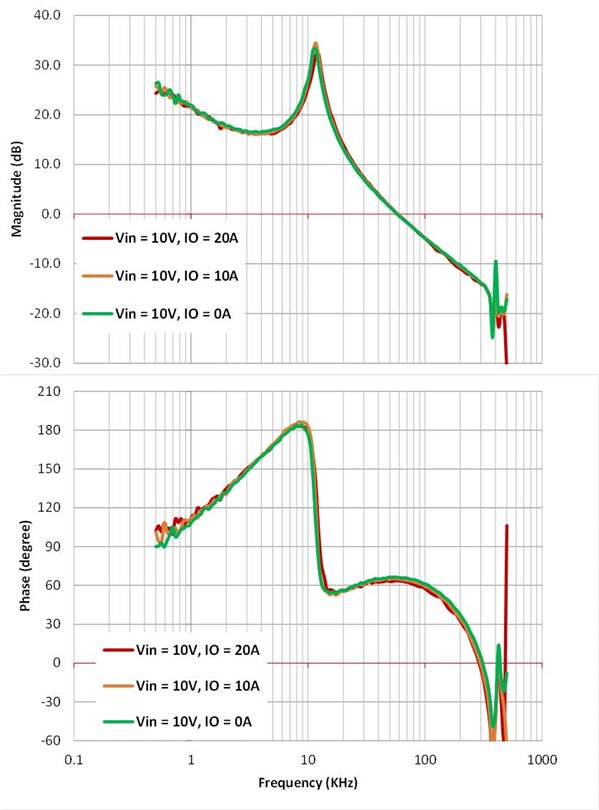

Figure 7 shows the measured Bode plot of the TPS53355. System phase margin is above 60 degrees, while gain margin is over 14dB.

Figure 7 Measured Bode plot of the

TPS53355

Figure 7 Measured Bode plot of the

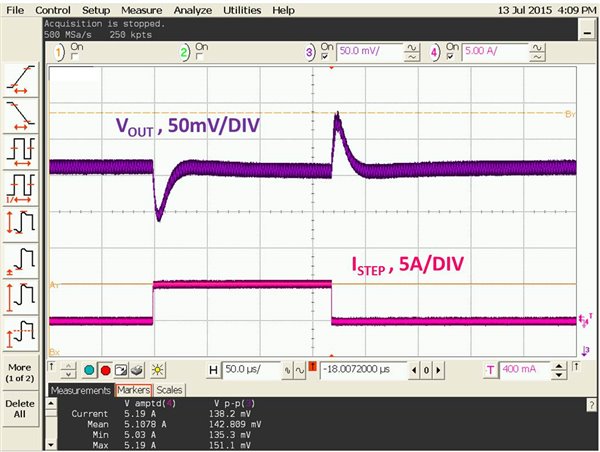

TPS53355Load-step transient response test was conducted per the application requirements. Figure 8 shows the transient-response performance. Overshoot and undershoot are below the ±99mV requirement.

Figure 8 Load-step transient

response

Figure 8 Load-step transient

responseThe output ripple meets the ±0.5% VOUT requirement.

Figure 9 Output ripple of the TPS53355 (VIN = 12.6V, Io = 20A,

oscilloscope in persistence mode)

Figure 9 Output ripple of the TPS53355 (VIN = 12.6V, Io = 20A,

oscilloscope in persistence mode)Simply adding a small capacitor from the FB pin to GND greatly reduced the output-capacitance requirement for D-CAP™ control with all-ceramic-output capacitors. My solution rendered a stable system with satisfactory application performance.

Additional Resources

- Read the blog post, “Power Tips: Calculating capacitance for load transients"

- Read the blog post, “Power Tips: How to measure Bode plots with DCAP regulators"

- Download the High Power Density Buck Converter with Integrated FET DCAP Regulator TI Design reference design

- Download the TPS53355 data sheet

- Read all Power Tips blogs

IMPORTANT NOTICE AND DISCLAIMER

TI PROVIDES TECHNICAL AND RELIABILITY DATA (INCLUDING DATASHEETS), DESIGN RESOURCES (INCLUDING REFERENCE DESIGNS), APPLICATION OR OTHER DESIGN ADVICE, WEB TOOLS, SAFETY INFORMATION, AND OTHER RESOURCES “AS IS” AND WITH ALL FAULTS, AND DISCLAIMS ALL WARRANTIES, EXPRESS AND IMPLIED, INCLUDING WITHOUT LIMITATION ANY IMPLIED WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE OR NON-INFRINGEMENT OF THIRD PARTY INTELLECTUAL PROPERTY RIGHTS.

These resources are intended for skilled developers designing with TI products. You are solely responsible for (1) selecting the appropriate TI products for your application, (2) designing, validating and testing your application, and (3) ensuring your application meets applicable standards, and any other safety, security, or other requirements. These resources are subject to change without notice. TI grants you permission to use these resources only for development of an application that uses the TI products described in the resource. Other reproduction and display of these resources is prohibited. No license is granted to any other TI intellectual property right or to any third party intellectual property right. TI disclaims responsibility for, and you will fully indemnify TI and its representatives against, any claims, damages, costs, losses, and liabilities arising out of your use of these resources.

TI’s products are provided subject to TI’s Terms of Sale (www.ti.com/legal/termsofsale.html) or other applicable terms available either on ti.com or provided in conjunction with such TI products. TI’s provision of these resources does not expand or otherwise alter TI’s applicable warranties or warranty disclaimers for TI products.

Mailing Address: Texas Instruments, Post Office Box 655303, Dallas, Texas 75265

Copyright © 2023, Texas Instruments Incorporated