SSZTCG6 july 2015 LM2771 , LM2775 , TPS3619

Wouldn’t it be much easier if all devices in an electronic design operated from the same supply voltage? Unfortunately, not all functions have the same supply-voltage requirements, requiring the generation of multiple supply rails within a given device design. You may need multiple supply voltages, even for an IC like a high-performance data converter.

If a voltage rail does not need to be particularly efficient, requires a low load current or just needs to be the very lowest cost, then a simple low-dropout regulator (LDO) is usually the best approach.

If a voltage rail requires a very high load current (say, greater than a few hundred milliamps), or needs low output ripple, consider an inductive solution, with its high efficiency.

But for solutions requiring relatively low load currents and efficiencies higher than LDOs, plus cost/size constraints, a charge-pump DC/DC device is worth considering.

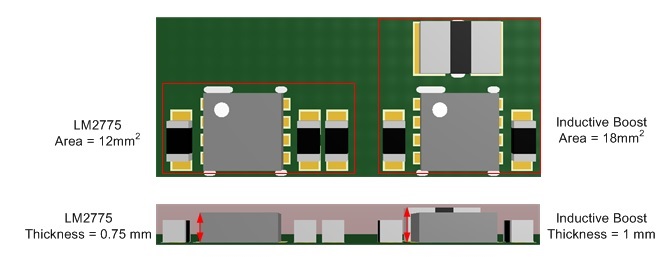

Figure 1 Example of a Charge Pump

(12mm2) Versus an Inductive Solution (29mm2):

VIN = 3.0V to 4.5V and vOUT = 5V at 150mA

Figure 1 Example of a Charge Pump

(12mm2) Versus an Inductive Solution (29mm2):

VIN = 3.0V to 4.5V and vOUT = 5V at 150mACharge-pump DC/DC devices enable you to generate different output voltages (boost/buck/inverted) from a given input voltage. These devices only require a flying capacitor to support the charge pump itself and decoupling capacitors for input- and output-voltage pins. Figure 1 above highlights an example where an application needing a Vout of 5V with a load of 150mA compares between a charge pump boost and an inductive boost – a greater than 30% solution size saving.

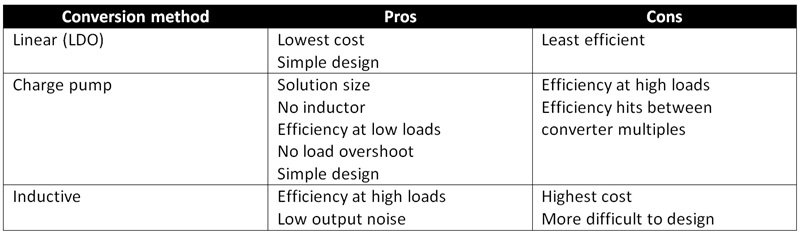

Figure 2 summarizes the different voltage-conversion methods.

Figure 2 Design Criteria Comparisons

between DCDC Converter Approaches

Figure 2 Design Criteria Comparisons

between DCDC Converter Approaches A charge-pump solution can be useful if you need a single special-voltage rail for a specific low-load device within a system. In such a system, an inductive DC/DC usually supports the overall system rail given the higher load requirement. A switch-capacitor DC/DC generates the specific light-load rail – be it a boost, a buck or an inverted voltage from the main system rail – and does so with only the use of capacitors, with reasonable efficiency, in a small solution size and very cost-effectively.

Additional Resources

- Learn more about “The Forgotten Converter” in this white paper.

- Find help deciding between a charge pump, inductor-based converter or LDO.

- Simulate your design using the LM2775.