SSZTCX7 February 2024 LM5180-Q1 , UCC14240-Q1 , UCC25800-Q1

A variety of industrial and automotive systems use isolated bias supplies. Most existing approaches using flyback or push-pull converters for isolated bias power (see the Texas Instruments [TI] “Isolated Bias Power Supply Architecture and Topology Trade-Offs for HEV/EVs” presentation and “HEV/EV Traction Inverter Power Stage with 3 Types of IGBT/SiC Bias-Supply Solutions Reference Design”) require significant design effort and rely on a low leakage inductance isolation transformer.

In this power tip, I’d like to present two approaches that both reduce design complexity and noise coupling in isolated bias supplies. One approach, useful for multiple isolated outputs and overall output power to 8 W, uses the inductor-inductor-capacitor (LLC) topology along with a half-bridge driver such as TI’s UCC25800-Q1. The second approach, which integrates the isolation transformer and is useful for up to 1.5 W and one isolated output, uses a single integrated circuit (IC) such as TI’s UCC14240-Q1. That device contains both the power and feedback isolation and needs only filter capacitors and resistor-dividers to complete the design.

The complexity of isolated power, especially at low power levels, is a significant cost-, size- and design-resource burden. The most common topology for low power is the flyback converter. Conventional flyback converters use an optocoupler to feed back the output voltage from the secondary side to the controller IC on the primary side. Low-cost optocouplers are not an option in demanding automotive and industrial environments because of long-term reliability concerns. Even with closed-loop regulation, only one of the flyback outputs is really fully regulated. Flyback converters with primary-side regulation that eliminate any optocoupler requirement, such as TI’s LM5180-Q1, are available. However, the need for a low-leakage transformer, with its noise and isolation challenges, remain.

With most converter topologies, a low-leakage transformer is key to delivering power across the isolation barrier efficiently. Methods to reduce transformer leakage inductance, such as closely coupled windings and interleaving, generally increase the primary to secondary capacitance. This capacitance spreads noise from both the isolated converter switching itself, and the circuitry to which the isolated output is connected, such as a high-side switch in a traction inverter or an onboard charger. These switches can swing up and down at over 100 V per nanosecond. Also, there is a significant cost and size burden in transformers requiring both high (several kilovolts) reinforced isolation and low leakage inductance.

My focus here will be on the highly isolated power needs of approximately 8 W or less, where the available primary-side power is in the range of 12 VDC to 24 VDC. A high isolation rating (3-kV root mean square [RMS] or greater) is necessary to meet safety isolation where power is needed in circuitry connected to the AC mains or to 400- and 800-V batteries. Application examples include isolated bias power in onboard chargers for electric vehicles and traction inverters, which typically need roughly +15 V for rapid switch turnon and roughly –5 V for rapid switch turnoff, with the return tied to the emitter or source of the high-power switch.

One IC for multiple outputs and up to 8 W: the UCC25800-Q1

The LLC topology (see the application note, “Bias Supply Design for Isolated Gate Driver Using UCC25800-Q1 Open-Loop LLC Transformer Driver”) allows good load regulation of the isolated output voltage without feedback. This topology actually uses the leakage inductance of the transformer to provide soft switching and greatly reduce switching losses in the main switches. The fact that the leakage inductance effect on output regulation can be effectively tuned out by the coupling capacitance allows the use of high isolation transformers, on which the primary and secondary are on separate bobbins. This results in very low coupling capacitance for low system noise and high reinforced (several kilovolts) isolation for safety purposes. The soft switching, combined with the tuning out of the leakage inductance by the coupling capacitor, turns leakage inductance from being an enemy to being a friend.

This approach does require a regulated input DC voltage for power to avoid the need for secondary-side regulation. With a two-switch half bridge (for the low power levels needed here), a square wave of one-half the input voltage is applied to the transformer primary. For automotive applications, there is often a regulated DC voltage of 12 V or 24 V for other purposes. If a pre-regulator is necessary, a simple single-ended primary-inductor converter will provide the regulated 15- or 24-V input power. The design burden of this pre-regulator will often be much less than the challenge of taming the system noise caused by the low-leakage flyback transformer.

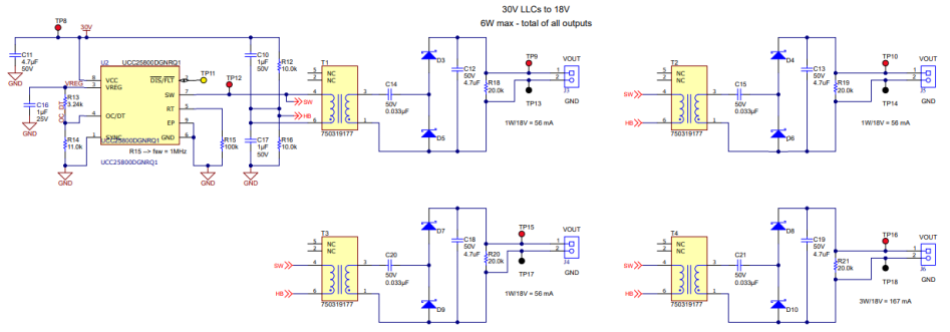

Published design examples with the UCC25800-Q1 include the “Pre-Regulated Isolated Driver Bias Supply Reference Design for Traction Inverter Applications”: four outputs, 6 W total off 30 V (shown in Figure 1 and Figure 2) and the “Isolated IGBT and SiC Driver Bias Supply Reference Design for Traction Inverter Applications,” with +16 V/–5V for 6.6-W maximum off of 24 V. The transformer used in the insulated-gate bipolar transistor (IGBT) and silicon carbide (SiC) driver reference design has only 1.3-pF typical of primary to secondary capacitance, versus 20-pF typical for a flyback transformer of similar power. This reduction by more than a factor of 10 in capacitance represents at least a 20-dB reduction of noise spread in the system. The only primary and secondary interfaces are the transformers.

Figure 1 From the pre-regulated

reference design schematic—the isolated four-output converter. Source: Texas

Instruments

Figure 1 From the pre-regulated

reference design schematic—the isolated four-output converter. Source: Texas

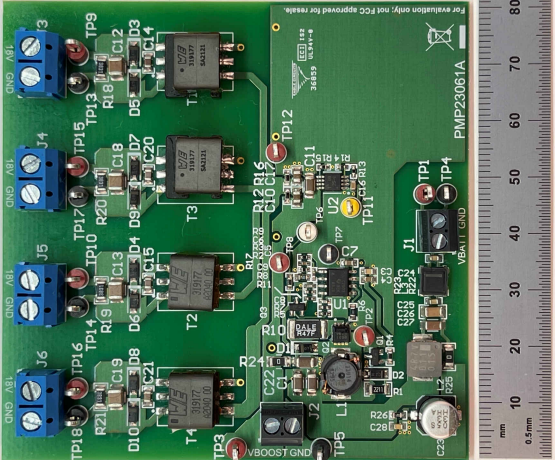

Instruments Figure 2 Pre-regulated reference design

assembled board, including boost circuit from 6 VIN. Source: Texas

Instruments

Figure 2 Pre-regulated reference design

assembled board, including boost circuit from 6 VIN. Source: Texas

InstrumentsOutput regulation of the four outputs varied in range from 16.25 V to 17.27 V for loads from 10% to 100% of the maximum load.

A simpler approach when you need less than 2 W of isolated power: the UCC14240-Q1

An even simpler approach is a self-contained isolated converter IC that integrates the transformer and secondary to primary feedback, with only the input/output capacitors and voltage dividers needed to set both the positive and negative outputs. The power stage includes a primary-side full bridge, an isolation transformer with very low primary to secondary capacitance of approximately 3.5 pF to minimize system noise coupling, and a full-bridge output rectifier. Choosing a switching frequency of 13 MHz both enables this low primary to secondary capacitance and keeps its own switching noise well removed from any bands of concern in automotive applications. The internal feedback of the IC allows the input voltage to vary more than ±10% from nominal and still give well-regulated positive and negative voltages to within 1.3% of nominal output. This IC shows that topology complexity - which is fully contained inside the IC – is not a design burden.

The UCC14240-Q1 works off 21 VIN to 27 VIN and targets gate-drive applications for IGBTs and SiC metal-oxide semiconductor field-effect transistors in traction inverters, onboard chargers and motor control, with a typical positive voltage of +15 V to turn on the device, and a typical negative voltage of –5V to turn off the device. However, other combinations of positive and negative voltages are allowed within the 18-V to 25-V total.

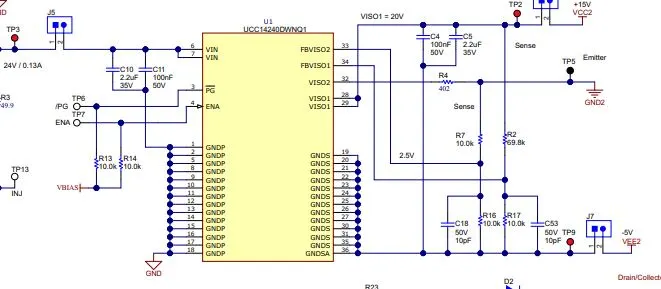

Figure 3, Figure 4, and Figure 5 illustrate a self-contained high-isolation example with planned 3,000-VRMS isolation as part of an “SPI-Programmable Gate Driver and Bias Supply Reference Design.” U1 is the actual DC/DC isolated power supply, U3 is a smart isolated gate driver, and U2 with Q1 and L1 is a car battery to DC converter. Note the 8-mm primary-to-secondary isolation valley.

Figure 3 From the automotive

“SPI-Programmable Gate Driver and Bias Supply with Integrated Transformer

Reference Design” schematic - the isolated +15-V/–5-V converter. Source: Texas

Instruments

Figure 3 From the automotive

“SPI-Programmable Gate Driver and Bias Supply with Integrated Transformer

Reference Design” schematic - the isolated +15-V/–5-V converter. Source: Texas

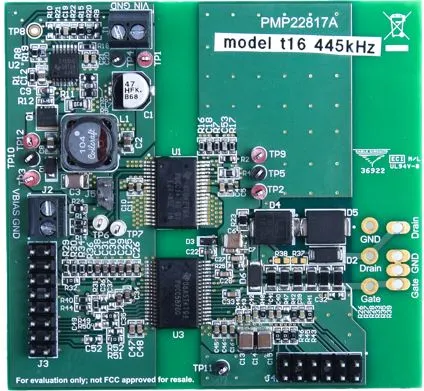

Instruments Figure 4 Automotive SPI-programmable

reference design assembled board. Source: Texas Instruments

Figure 4 Automotive SPI-programmable

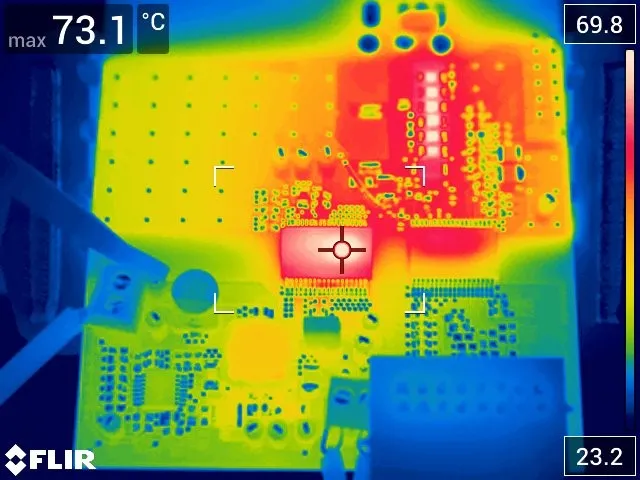

reference design assembled board. Source: Texas Instruments Figure 5 Automotive SPI-programmable

reference design thermal image with 1.6-W loading. Source: Texas

Instruments

Figure 5 Automotive SPI-programmable

reference design thermal image with 1.6-W loading. Source: Texas

InstrumentsThese two approaches make providing isolated power for gate drives in high-power inverters and battery chargers much less of a design challenge, with the added bonus of also reducing radio-frequency noise at the system level. The first approach enables multiple isolated outputs controlled by a single IC. With the second approach, one IC with only filter capacitors and divider resistors provides a complete isolated power solution.

Related Content

- Power Tips #112: Onboard fixtures for fault testing

- Power Tips #111: Why current sensing is a must in collaborative, mobile robots

- Power Tips #110: How parasitics create an unexpected EMI filter resonance

- Power Tips #109: Five major trends in power supply design for servers

- Creating an isolated power supply creates many challenges

- Isolated power conversion: making the case for secondary-side control

Previously published on EDN.com.