-

How to design a limited power source industrial AC/DC power supply with minimal components – part 1

How to design a limited power source industrial AC/DC power supply with minimal components – part 1

Latif Ameer

DIN rail power supplies in industrial equipment.

In this two-part series, I’ll explain the basic details of limited power source (LPS) requirements and how you can optimize the feedback loop with the UCC28740 primary-side regulated (PSR) flyback controller to reduce the overall components in high-power-density industrial DIN rail power supplies.

Increasingly, the responsibilities of a power-supply designer extend beyond merely meeting a product’s functional specifications. The latest-generation products need to be robust and safe over various operating conditions such as overcurrent, overvoltage, short circuit and limited power output.

To meet safety requirements for equipment powered using industrial power supplies, it is important to precisely limit current and power during all operating circumstances, which include normal conditions, load-transient conditions and severe output-fault conditions. In addition, the voltage should exceed certain limits to prevent electrical shocks for the end user. Limiting power, current and voltage also has a multitude of associated benefits, which include reduced wire gauges for output interconnections, reduced component stress for downstream converters, reduced system cost and increased system reliability.

Safety standards such as IEC - International Electrotechnical Commission IEC 60950-1 and the National Electrical Code (NEC) define these limits for voltage, current and power.

For instance, IEC 60950-1 covers LPS requirements of power supplies in Clause 2.5 of the standard, shown in Table 1. Table 2B of IEC 60950-1 Clause 2.5 elucidates the restrictions for power sources for current and apparent power for cases where you do not use external overcurrent protection such as inherently limited source.

|

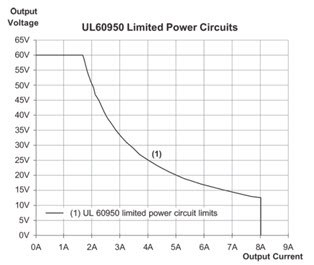

Figure 1 is a graphical representation of Table 1.

Figure 1 Graphical view of UL60950

limited power circuits

Figure 1 Graphical view of UL60950

limited power circuitsSimilarly, the NEC also sets guidelines for maximum possible voltage, current and power to govern the installation of wiring and equipment in commercial buildings and residential areas.

In the next installment of this series, I’ll explain the protection implementation with minimal components.

Additional resources:

- Explore these industrial power-supply designs:

IMPORTANT NOTICE AND DISCLAIMER

TI PROVIDES TECHNICAL AND RELIABILITY DATA (INCLUDING DATASHEETS), DESIGN RESOURCES (INCLUDING REFERENCE DESIGNS), APPLICATION OR OTHER DESIGN ADVICE, WEB TOOLS, SAFETY INFORMATION, AND OTHER RESOURCES “AS IS” AND WITH ALL FAULTS, AND DISCLAIMS ALL WARRANTIES, EXPRESS AND IMPLIED, INCLUDING WITHOUT LIMITATION ANY IMPLIED WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE OR NON-INFRINGEMENT OF THIRD PARTY INTELLECTUAL PROPERTY RIGHTS.

These resources are intended for skilled developers designing with TI products. You are solely responsible for (1) selecting the appropriate TI products for your application, (2) designing, validating and testing your application, and (3) ensuring your application meets applicable standards, and any other safety, security, or other requirements. These resources are subject to change without notice. TI grants you permission to use these resources only for development of an application that uses the TI products described in the resource. Other reproduction and display of these resources is prohibited. No license is granted to any other TI intellectual property right or to any third party intellectual property right. TI disclaims responsibility for, and you will fully indemnify TI and its representatives against, any claims, damages, costs, losses, and liabilities arising out of your use of these resources.

TI’s products are provided subject to TI’s Terms of Sale (www.ti.com/legal/termsofsale.html) or other applicable terms available either on ti.com or provided in conjunction with such TI products. TI’s provision of these resources does not expand or otherwise alter TI’s applicable warranties or warranty disclaimers for TI products.

Mailing Address: Texas Instruments, Post Office Box 655303, Dallas, Texas 75265

Copyright © 2024, Texas Instruments Incorporated