How MCUs increase system performance in robot motor control designs

Robotic systems automate repetitive tasks, handling complex, powerful motions and working in environments that are dangerous or harmful to humans. More integrated, higher-performance microcontrollers (MCUs) enable higher power efficiency and smoother and safer motion with much higher accuracy, therefore increasing productivity and automation. For example, higher accuracy – sometimes within 0.1 mm – is important for applications that handle laser welding, precision coatings, or inkjet or 3D printing.

The number of axes in a robot arm and the type of control architecture needed (either centralized or distributed, also known as decentralized) will ultimately determine the right MCU or motor-control integrated circuit (IC) for that system. Modern factories use a mix of robots with varying numbers of axes, defined as the degree of movement and rotation across x, y or z planes, in order to handle different phases of manufacturing; therefore, there are various control architectures throughout the factory floor.

It’s important to choose MCUs with additional performance headroom to provide future scalability, as well as the capacity to support add-on features. Planning for scalability and additional features can reduce cost, time and complexity during the design process.

In this article, I’ll explore centralized and distributed motor-control architectures and the design considerations for the integrated, real-time MCUs enabling them. To read about key motor drive design challenges for robotics, read our technical article, “How motor drive innovations are helping solve robotic movement design challenges.”

A centralized architecture

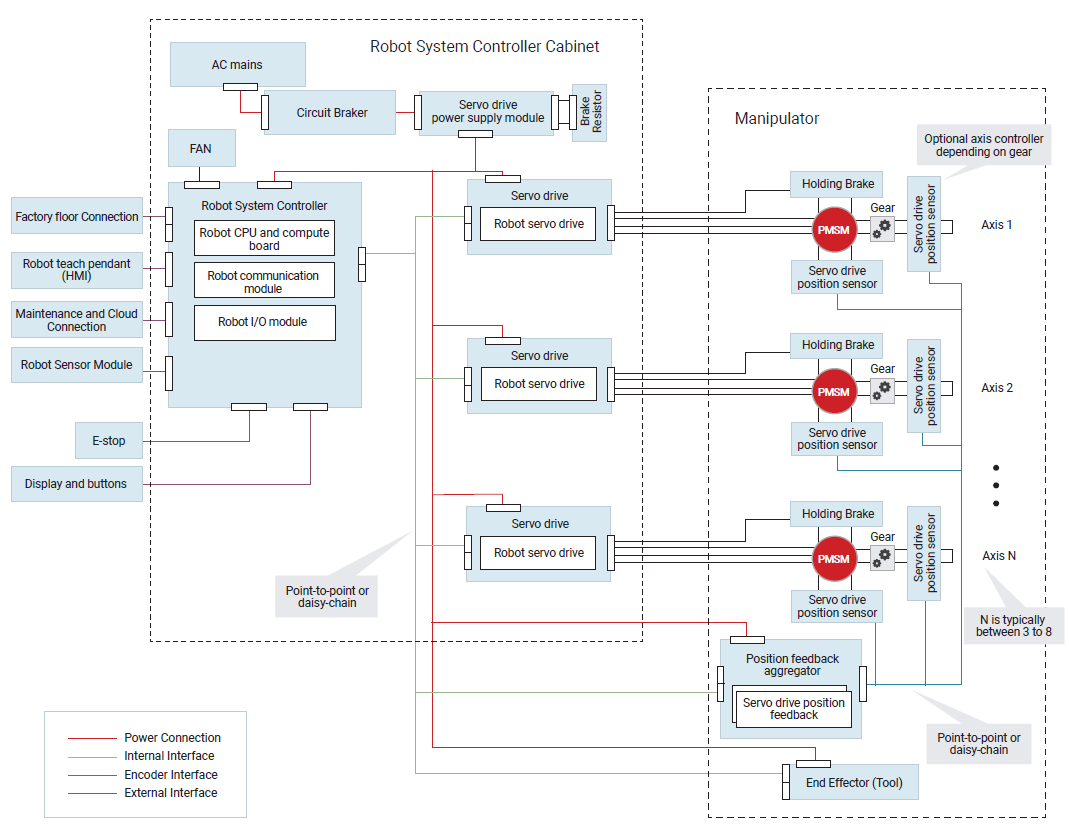

In a centralized system (Figure 1), one MCU controls multiple axes. This approach is effective at handling heat dissipation in higher-power motor drivers (typically above 2-3 kW) that require large heat sinks and cooling fans. In this architecture, position data is usually acquired externally through a resolver board or aggregator connected to the encoders.

Figure 1 Block diagram of a centralized motor-control architecture for multiple-axis systems

Figure 1 Block diagram of a centralized motor-control architecture for multiple-axis systemsTypically, in this architecture, multiple power stages are on the same printed circuit board or in close proximity; thus, one MCU can control multiple axes. This approach simplifies the real-time control and synchronization between multiple axes, as there is no need for longer communication lines between multiple motor-control MCUs.

The motor-control MCU/microprocessor in a centralized architecture mainly requires high-performing real-time processing cores such as Arm® Cortex®-R5F cores or digital signal processors, real time communication interfaces such as EtherCAT, and enough pulse-width modulation (PMW) channels and peripherals for voltage and current sensing. MCUs such as the AM2432 can enable scalable multiple-axis systems and offer real-time control peripherals for as many as six axes and real-time communications in a single chip.

In the past, field-programmable gate arrays or application-specific integrated circuits were primarily used for centralized motor control in automated systems. However, the high level of integration and cost-effectiveness of Arm Cortex MCUs can help you meet your system’s performance requirements while also enabling design scalability and flexibility.

While centralized control architectures can meet the performance and efficiency design requirements of high-powered automated systems such as heavy-payload industrial robots, they do require additional cables from the cabinet to the mechanical motor in the joint, as well as from the position sensors to the aggregators. Those wires do not only cost more, they also wear out and require maintenance.

A decentralized architecture

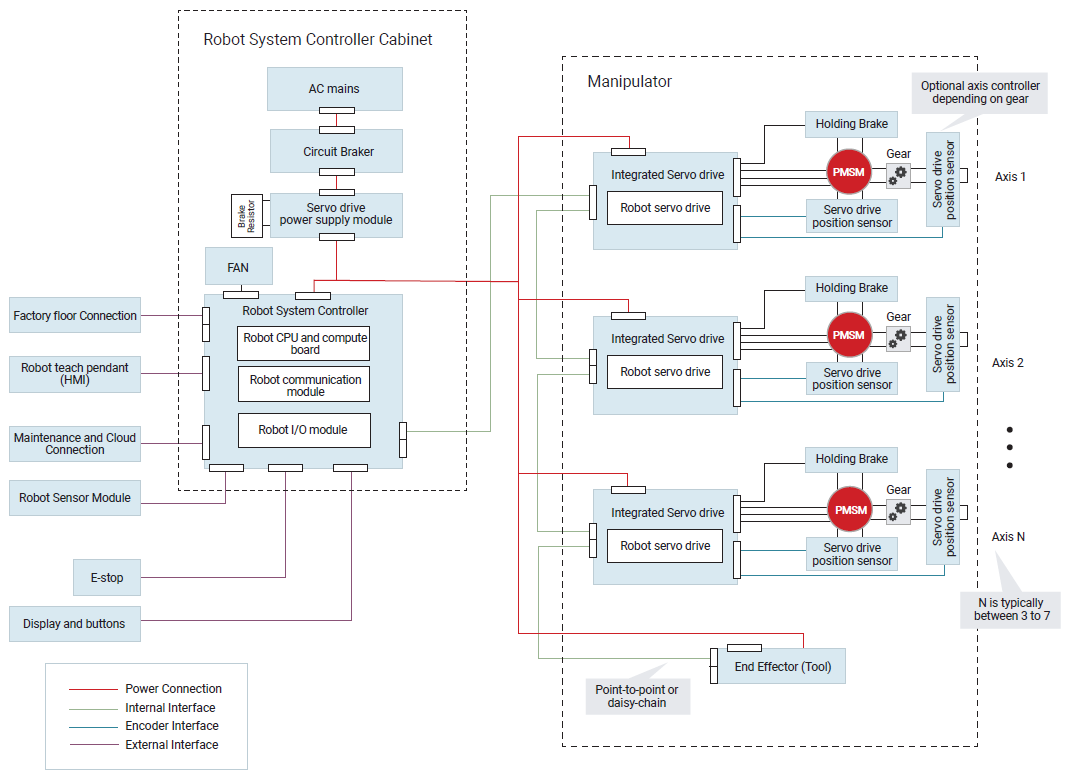

Decentralized architectures (Figure 2) have recently grown in popularity for systems with lower power requirements, and have become the standard approach for collaborative robot (cobot) manipulators.

Figure 2 Block diagram of a decentralized motor control architecture for single-axis systems

Figure 2 Block diagram of a decentralized motor control architecture for single-axis systemsDecentralized architectures integrate multiple single-axis motor drives into each joint within the robot, connected and synchronized through a real-time communication interface such as EtherCAT. Each drive usually controls one single axis and handles certain safety functions locally. Therefore, each MCU needs real-time control and communication capabilities, motor-control peripherals for a single axis, three to six PWM channels, on-chip successive approximation register analog-to-digital converters, or delta-sigma modulator inputs.

In these applications, the position sensor usually sits next to the MCU, so these MCUs need a digital or analog interface to read data from the position sensor. While this architecture requires more MCUs, cost reductions at the system level can be significant, since you’ll need less cabling between the power bus and communication interface. Modern real-time MCUs such as the TMS320F28P650DK integrate all necessary peripherals including safety peripherals, which can enable single- or two-chip solutions for an integrated axis in decentralized architectures with high performance at a small size.

Conclusion

While motors may not be the trendiest system in a robot – especially when compared to artificial intelligence-enabled systems – they are the “muscles” that keep factories moving. They might be the most crucial part of modern manufacturing, so selecting the right control device deserves a lot of consideration. As these devices become more integrated, additional capabilities such as edge computing and wireless connectivity may make their way into motor-control designs.

IMPORTANT NOTICE AND DISCLAIMER

TI PROVIDES TECHNICAL AND RELIABILITY DATA (INCLUDING DATASHEETS), DESIGN RESOURCES (INCLUDING REFERENCE DESIGNS), APPLICATION OR OTHER DESIGN ADVICE, WEB TOOLS, SAFETY INFORMATION, AND OTHER RESOURCES “AS IS” AND WITH ALL FAULTS, AND DISCLAIMS ALL WARRANTIES, EXPRESS AND IMPLIED, INCLUDING WITHOUT LIMITATION ANY IMPLIED WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE OR NON-INFRINGEMENT OF THIRD PARTY INTELLECTUAL PROPERTY RIGHTS.

These resources are intended for skilled developers designing with TI products. You are solely responsible for (1) selecting the appropriate TI products for your application, (2) designing, validating and testing your application, and (3) ensuring your application meets applicable standards, and any other safety, security, or other requirements. These resources are subject to change without notice. TI grants you permission to use these resources only for development of an application that uses the TI products described in the resource. Other reproduction and display of these resources is prohibited. No license is granted to any other TI intellectual property right or to any third party intellectual property right. TI disclaims responsibility for, and you will fully indemnify TI and its representatives against, any claims, damages, costs, losses, and liabilities arising out of your use of these resources.

TI’s products are provided subject to TI’s Terms of Sale (www.ti.com/legal/termsofsale.html) or other applicable terms available either on ti.com or provided in conjunction with such TI products. TI’s provision of these resources does not expand or otherwise alter TI’s applicable warranties or warranty disclaimers for TI products.

Mailing Address: Texas Instruments, Post Office Box 655303, Dallas, Texas 75265

Copyright © 2024, Texas Instruments Incorporated