SWRA680 November 2020 CC3100 , CC3120 , CC3135 , CC3200 , CC3220R , CC3220S , CC3220SF , CC3235S , CC3235SF

1.1 Crystal Oscillator Model

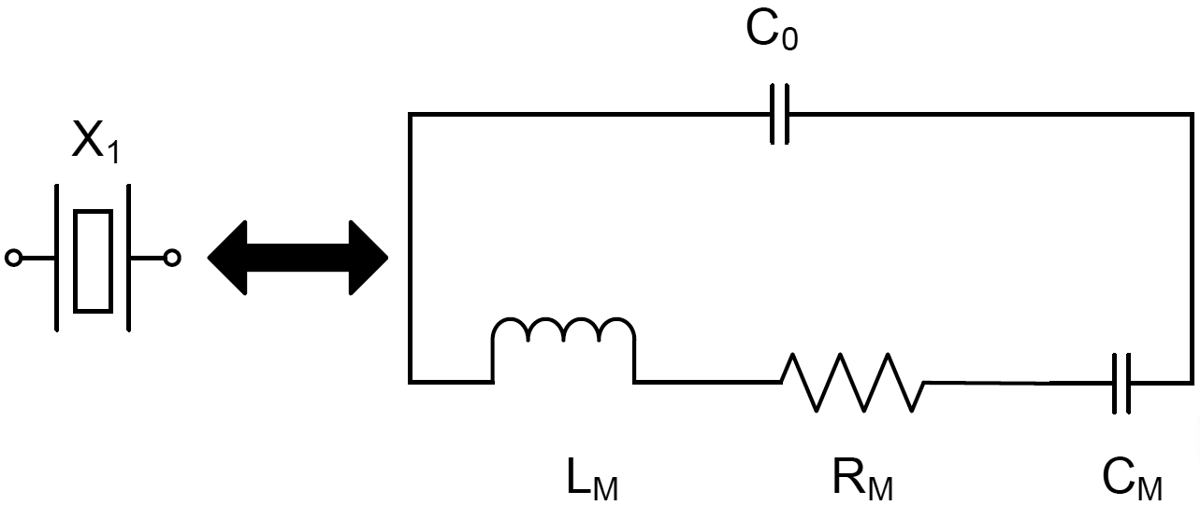

A crystal-based oscillator is formed by placing a crystal in the feedback loop of an oscillator circuit that provides sufficient gain and phase shift around the loop to start and sustain stable oscillations. A simplified electric model of a crystal is shown in Figure 1-1.

Figure 1-1 Crystal Symbol and the Electrical

Model

Figure 1-1 Crystal Symbol and the Electrical

ModelIt has R-L-C series components, called motional resistance (Rm), motional inductance (Lm), and motional capacitance (Cm). The capacitor in parallel, C0, is called the shunt capacitance, and models the package capacitance.