SWRU612 December 2023 CC3300 , CC3301 , CC3351

- 1

- Abstract

- Trademarks

- 1Introduction

-

2Schematic Considerations

- 2.1 Schematic Reference Design

- 2.2 Power Supply

- 2.3 Clock Source

- 2.4 Radio Frequency (RF)

- 2.5 Digital Interfaces

- 3Layout Considerations

3.4 XTAL

Figure 3-11 shows the placement and layout around the 40 MHz XTAL and its connections to the CC33xx IC.

Figure 3-11 is sampled from the BP-CC3301 design files.

Figure 3-11 40MHz XTAL From

BP-CC3301

Figure 3-11 40MHz XTAL From

BP-CC3301When integrating the XTAL, please follow these guidelines:

- The traces connecting the XTAL to the CC3301 (XTAL_P and XTAL_M) be as short as possible with matching trace length.

- Place a 150 Ω resistor on the XTAL_P pin as close as possible to the CC33xx.

- The two loading capacitors should be parallel to the edge of the XTAL.

- On layer below the crystal (layer 2), place a cutout underneath the area of the XTAL and the loading capacitors. Check on the layer below that (layer 3) has good ground underneath the same area. For a visual representation, see Figure 3-12.

- Wherever possible, there should be increased ground via stitching around the XTAL for optimal isolation.

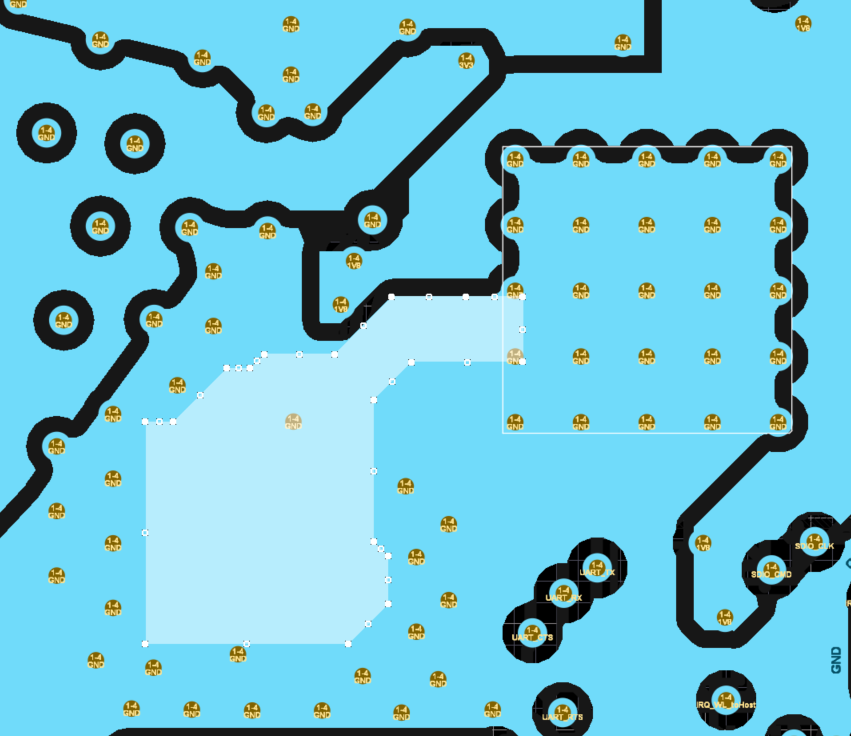

Figure 3-12 is sampled from layer 3 of the M2-CC3301 design files.

Figure 3-12 Reference Layout for Layer

Under XTAL Cutout

Figure 3-12 Reference Layout for Layer

Under XTAL Cutout