TIDT279 October 2022

1.1 Power and Load Connections and Test Points

Table 1-1 describes power and load connections. Table 1-2 lists the test point descriptions and devices.

Table 1-1 Power and Load Connections

| Connections | Description |

|---|---|

| J-BAT | VIN to LM5127-Q1 three-output power

supply 9-V to 18-V steady state main power input 2 × 1 5.08-mm terminal block |

| J8 and J8R | 8-V, 600-mA SEPIC output, 2 × Keystone 1212-ST

(0.187 in [4.75 mm] Quick-connect male solder connector non-insulated) |

| J5 and J5R | 5-V, 120-mA buck output, 2 × Keystone 1212-ST |

| J3 and J3R | 3.3-V, 6.7-A buck output, 2 × Keystone 1212-ST |

Table 1-2 Test Points

| Test Point | Description | Device |

|---|---|---|

| SP8 | 8-V output sense | MCX jack receptacle |

| TP801 | Bode plot injection point for the 8-V loop | |

| TP1 | Active low when any output active | |

| J55 | Jumper to disable 5 V | TSW-102-07-G-S |

| J33 | Jumper to disable 3.3 V | TSW-102-07-G-S |

| SP5 | 5-V output sense | MCX jack receptacle |

| TP501 | Bode plot injection point for the 5-V loop | |

| SP3 | 3.3-V output sense | MCX jack receptacle |

| TP301 | Bode plot injection point for the 3.3-V loop | |

| J300 | Dynamic current monitor off the 3.3-V dynamic load | Receptacle, ultra miniature coaxial, male pin, 50-Ω, SMT |

| J301 | Signal generator injection for the 3.3-V dynamic load | TSW-102-07-G-S |

| J302 | Not used, was to change 3.3-V loop speed |

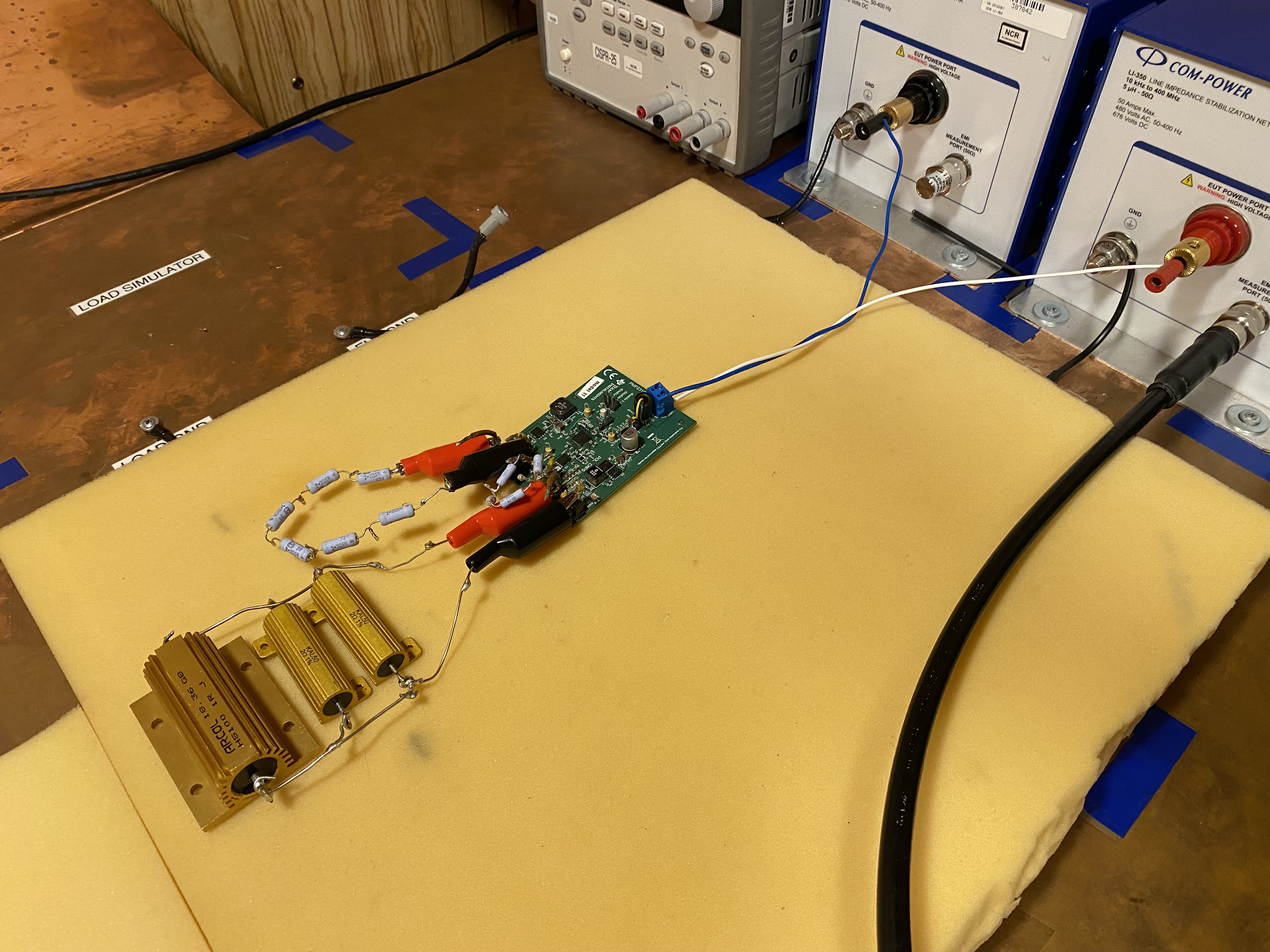

Figure 1-1 shows the test setup.

Figure 1-1 Test Setup for Conducted Emissions

Figure 1-1 Test Setup for Conducted Emissions