TIDT293 October 2022

3.4 INP

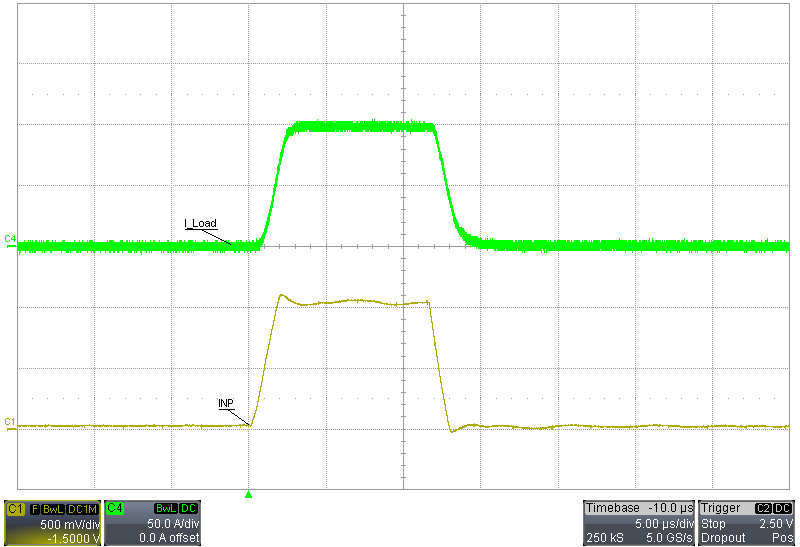

The INP is the driver reference signal for the high- and low-level transient as well as the slew rate. Monitor INP (TP7) to verify the signal is correct. Depending on U5, INP is at a 2.5-V or 1.25-V full scale load step.

The following scope plot is the INP signal relative to the load transient. For the 125-A variant, a 1-V INP signal produces a 100-A load step.

Figure 3-9 INP TLV431, 1 A to 100 A, 10-V

Output Load Transient

Figure 3-9 INP TLV431, 1 A to 100 A, 10-V

Output Load Transient