TIDT355 October 2023

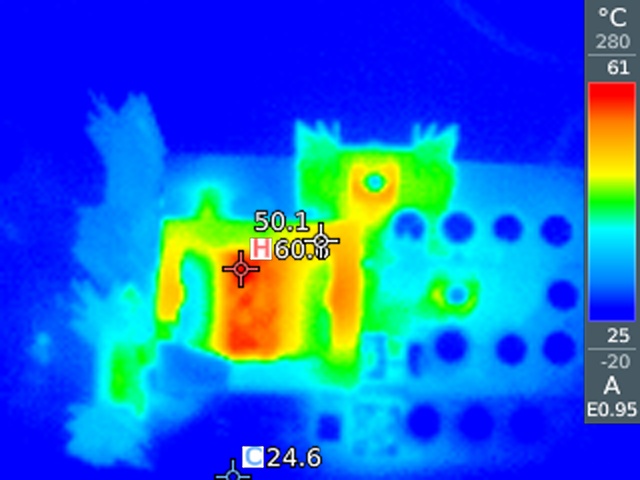

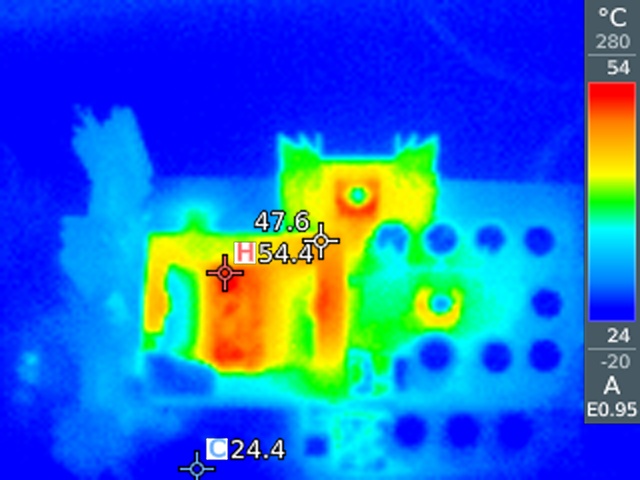

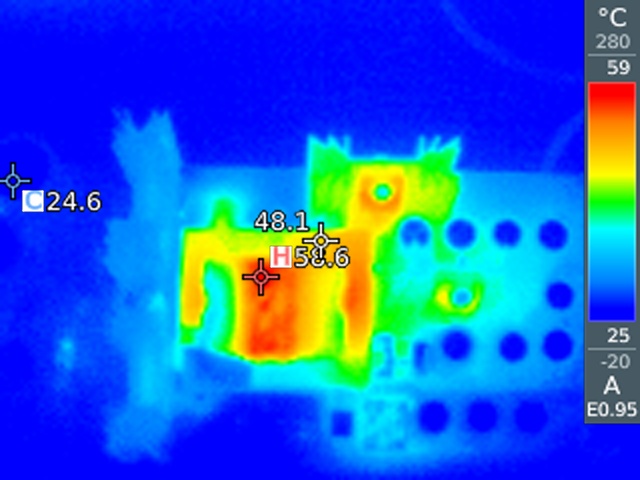

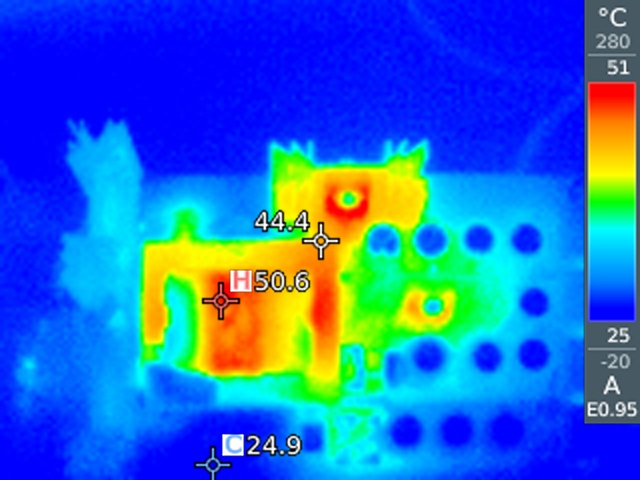

2.3 Thermal Images

Table 2-2 shows the thermal images at the four voltages. All images were captured with 25ºC ambient, after a 30-minute warm up and with an airflow of 200 LFM.

Table 2-2 Thermal Image Data

| Temperature (°C) | ||||

|---|---|---|---|---|

| 600 VIN | 800 VIN | 1000 VIN | 1500 VIN | |

| High-side switch Q1 | 46.3 | 47.3 | 49.4 | 55.4 |

| Low-side switch Q2 | 42.4 | 43.5 | 43.2 | 47.3 |

| Transformer | 52.2 winding 52.4 Core | 55.2 winding 54.3 core | 59.2 winding 55.2 Core | 62.3 winding, 58.2 Core |

| Secondary diode (24 V) | 50.5 | 52.1 | 53.1 | 55.2 |

| Secondary diode (15 V) | 47.2 | 48.5 | 49.3 | 53.2 |

| Secondary diode (–15 V) | 41.4 | 42.3 | 44.6 | 45.6 |

| Secondary diode (8 V) | 46.2 | 47.2 | 48.5 | 50.3 |

| UCC28740 | 34.5. | 36.1 | 39.2 | 41.2 |

Figure 2-2 Thermal Image at 1500

VIN Full Load

Figure 2-2 Thermal Image at 1500

VIN Full Load Figure 2-4 Thermal Image at 800 VIN Full Load

Figure 2-4 Thermal Image at 800 VIN Full Load Figure 2-3 Thermal Image at 1000

VIN Full Load

Figure 2-3 Thermal Image at 1000

VIN Full Load Figure 2-5 Thermal Image at 600

VIN Full Load

Figure 2-5 Thermal Image at 600

VIN Full Load