TIDT369B November 2023 – July 2024

3.3 Start-Up Sequence

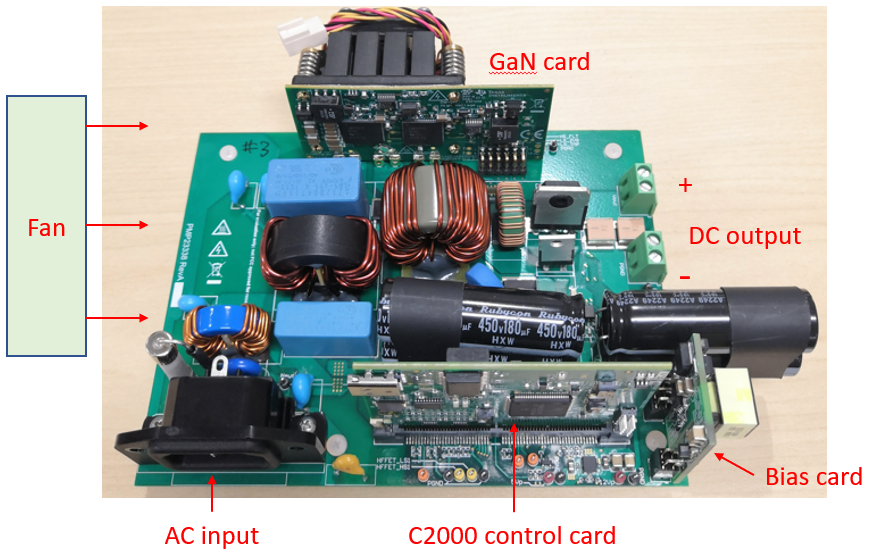

Figure 3-1 Test setup

Figure 3-1 Test setupStart-up sequence:

- Check GaN card, C2000 control card and Bias card are plugged in correctly and tightly

- Use a fan for cooling during test

- Connect a high voltage load to DC output, set load to 0.1A

- Connect AC source to AC input

- Use current probe to monitor AC input current, use voltage meter to measure DC output voltage

- Set AC output at 115V/60Hz, turn on AC, you see DC output voltage is regulated at about 385V

- Graduate increase load. Full load: 1800W@115VAC, 3600W@230VAC