TIDUC26A April 2022 – April 2024

4 Hardware Components

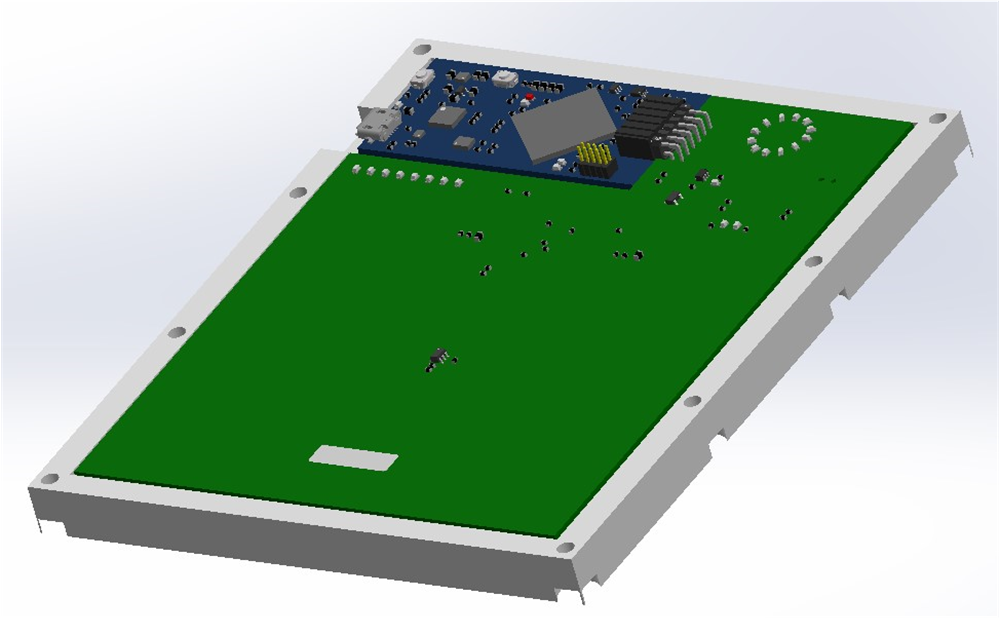

The 3D printed housing is separated into different components and assembled into the final housing. These components were designed for a Selective Laser Sintering process that uses Nylon 12 as the material. This gives the button surface slight flexibility to bend and allows for the magnetic dial to rotate smoothly. The design starts with a housing base that provides a rigid surface for the PCB to sit in as well as a hole for the USB cable and multiple holes for the bolts to secure the housing shut.

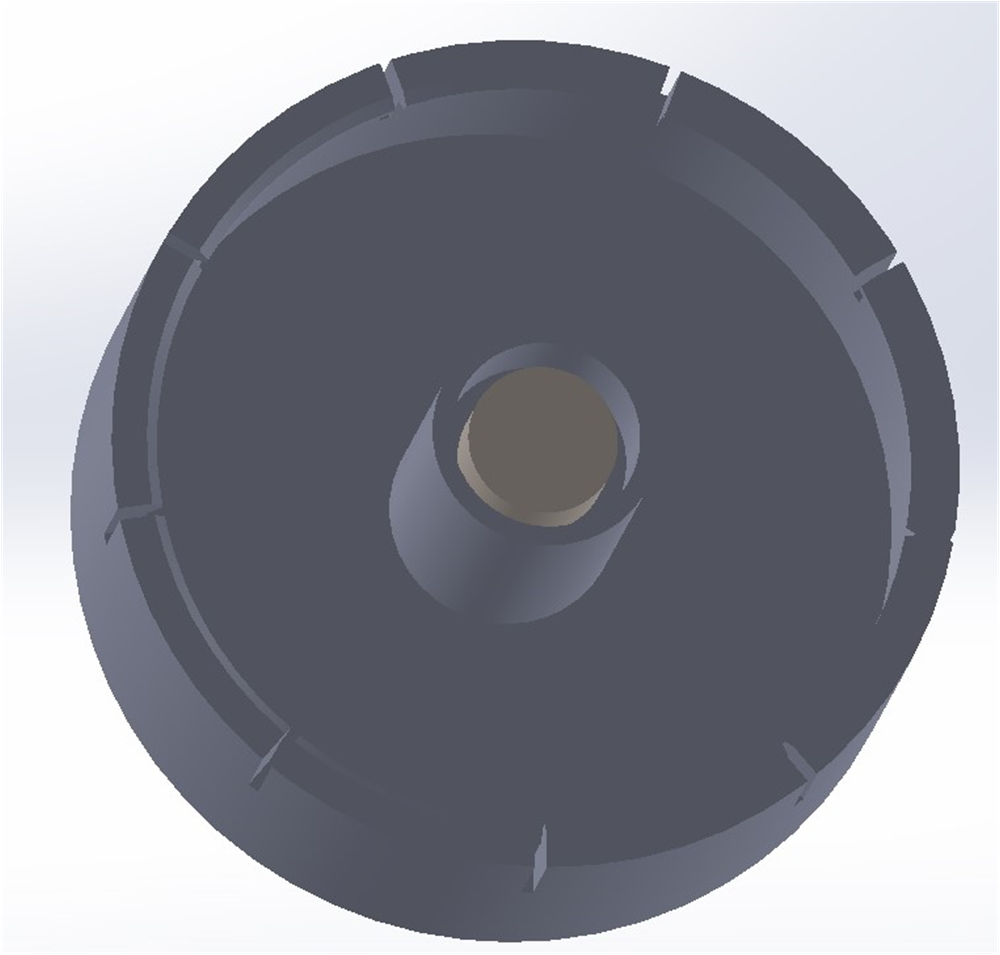

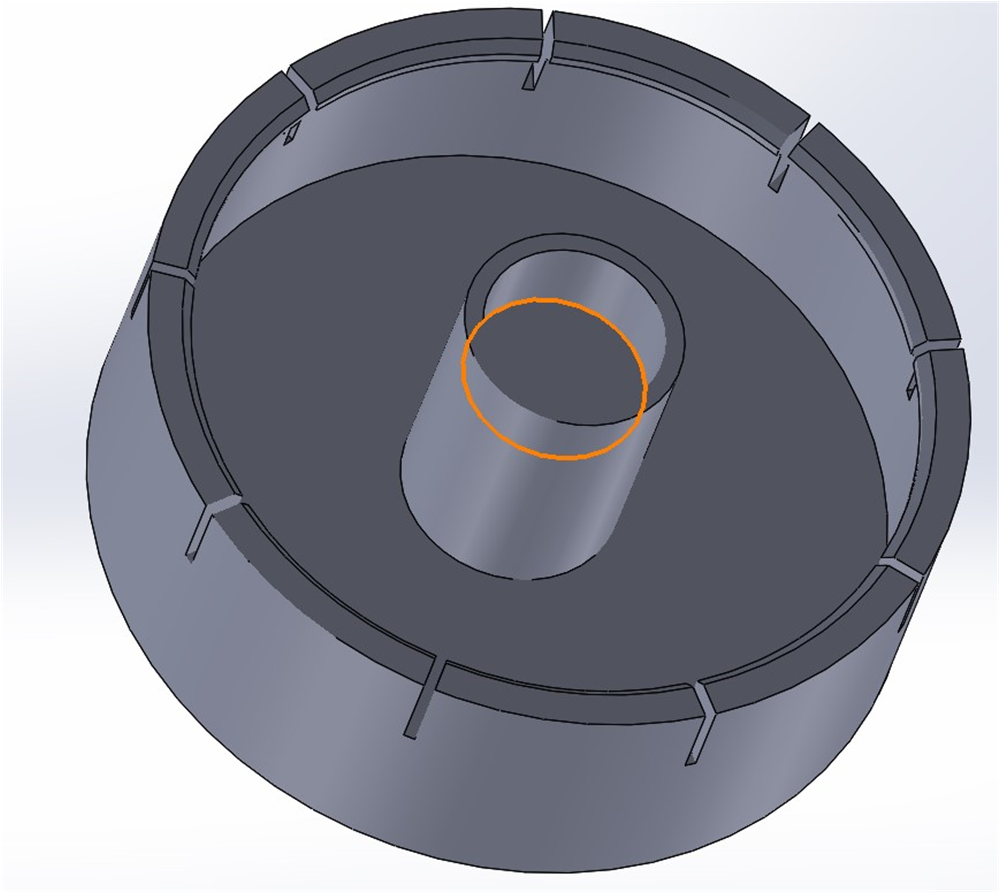

Figure 4-1 Housing Base

Figure 4-1 Housing BaseThe PCB rests inside the groove around the outside of the base along with the SCB attached.

Figure 4-2 Housing Base with PCB

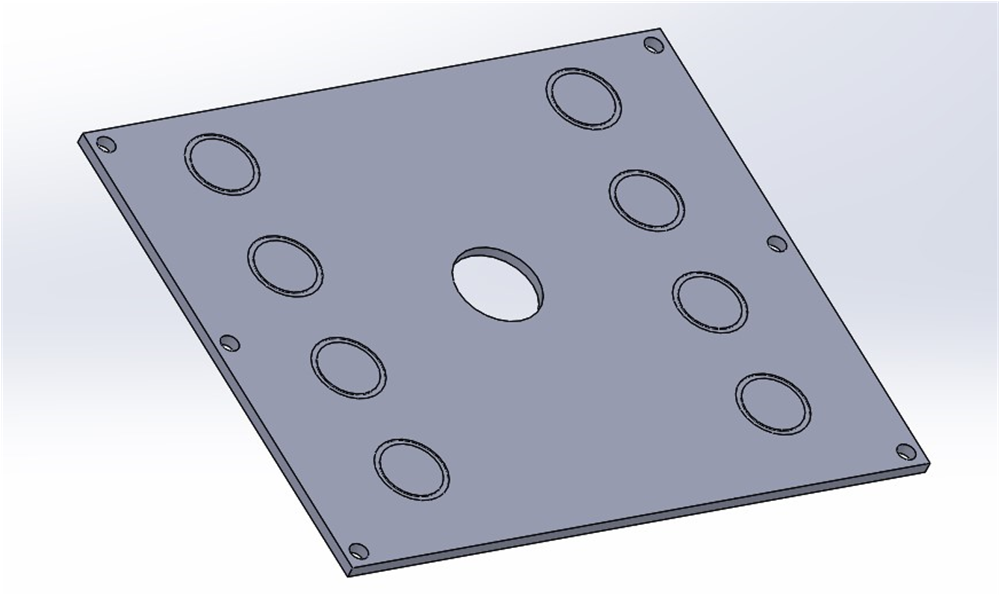

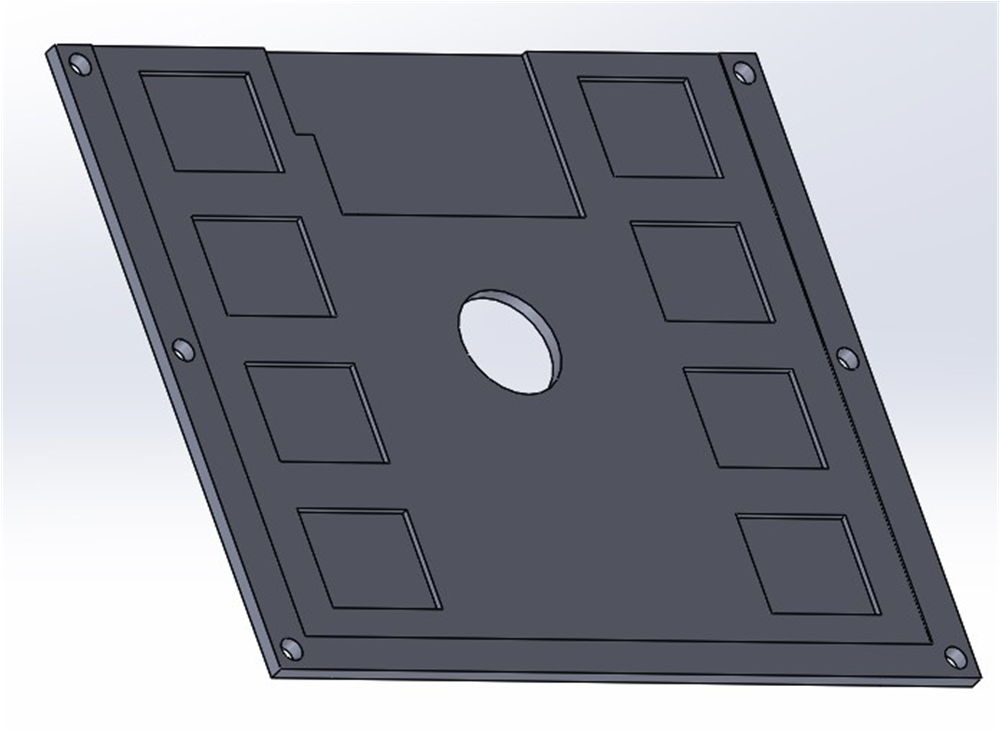

Figure 4-2 Housing Base with PCBThe top cover is broken into multiple parts to make it easier to print with some 3D printing technologies. These different parts are the button surface, a dial attachment, the dial, and a small cover for the top portion of the PCB. The button surface has grooves on the top to show where a button press needs to occur and a hole in the middle for the dial attachment piece to sit in. On the back, there are rectangular cutouts for the metal targets to be added into. To obtain the best mechanical isolation, the button cover is adhered to the PCB as well as bolted to the housing base. This portion of the design was built to match the button stackup design previously mentioned.

|

|

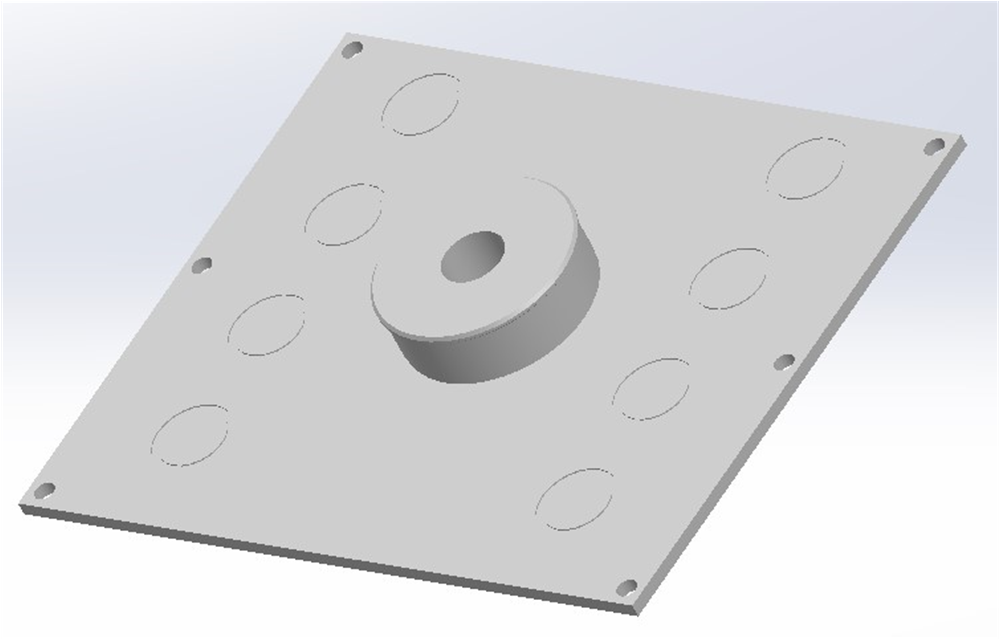

The dial attachment is a small round piece that sits in the hole of the button surface. The main purpose is to provide a spot for the dial to clip into. The dial attachment needs to be fixed to the button surface with glue to make sure that it does not move when using the button.

Figure 4-4 Button Cover with Dial

Attachment

Figure 4-4 Button Cover with Dial

AttachmentThe dial is designed to clip onto the dial attachment with a spring sitting between the two. The dial also has a small hole that the magnet gets glued into. This allows for the magnet to sit directly above the TMAG5273 for best rotational sensing measurements.

|

|

The small top cover has some cutouts to let the LEDs be visible even when the cover is on as well as a cutout for the USB cable to connect to the SCB. The main purpose of the top cover is to complete the housing and hold the SCB in place.

Figure 4-6 Full Assembly

Figure 4-6 Full Assembly