TIDUF23 may 2023

- Description

- Resources

- Features

- Applications

- 5

- 1System Description

- 2System Overview

-

3Hardware, Software, Testing Requirements,

and Test Results

- 3.1 Hardware Requirements

- 3.2 Test Setup

- 3.3 Test Procedure

- 3.4 Test Results

- 4General Texas Instruments High Voltage Evaluation (TI HV EVM) User Safety Guidelines

- 5Design and Documentation Support

- 6Terminology

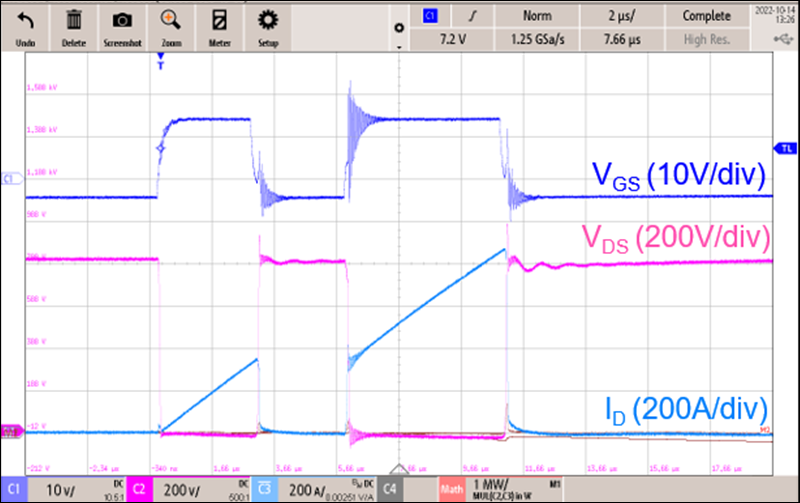

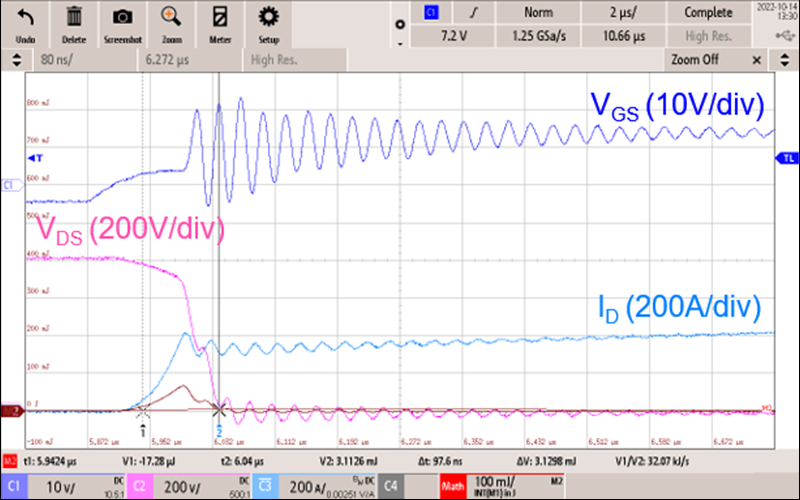

3.4.2 Isolated Gate Driver

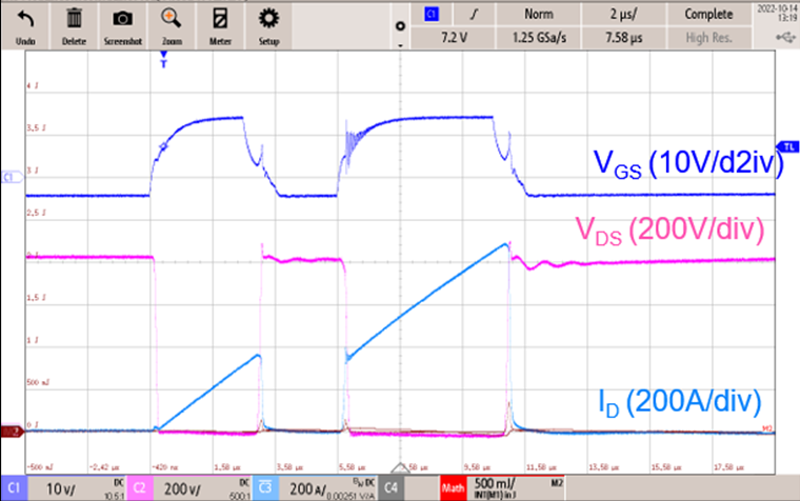

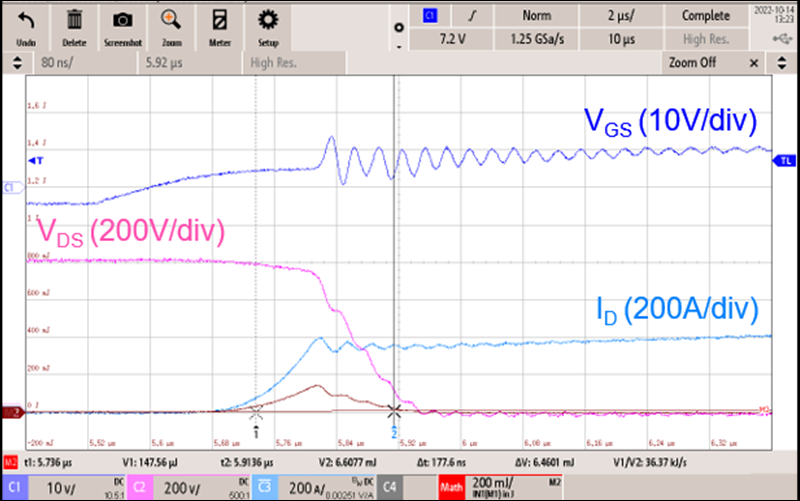

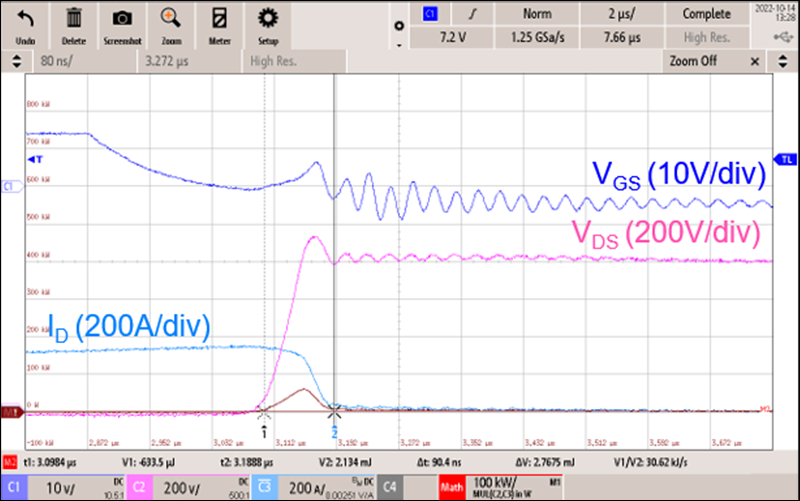

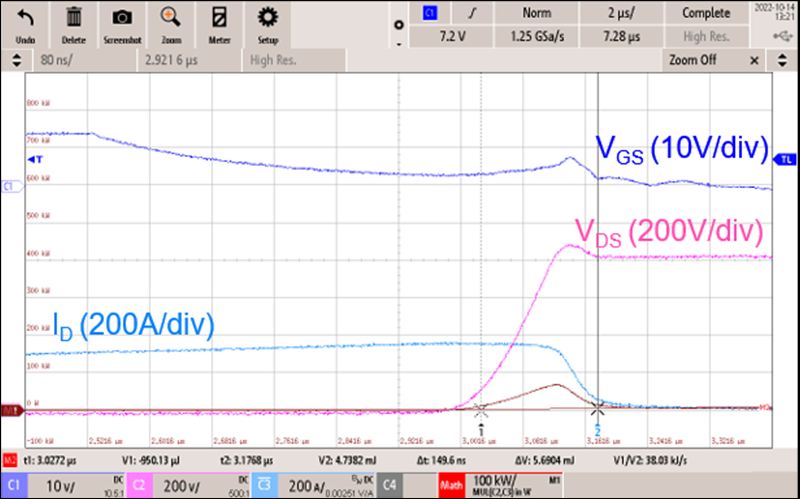

Double pulse test under 800 V is carried out to evaluate the switching behavior for the different adjustable gate drive strengths. The following results show the difference between weak drive (5 A) and strong drive (15 A). The waveforms of the gate-source voltage, drain-source voltage and drain currents are shown in the following figures. The turn off energy is measured at the end of the first pulse, while the turn on energy is measured at the beginning of the second pulse. The measurement results are presented in Figure 3-19.

Figure 3-19 Double Pulse Test with

Weak Drive Strength

Figure 3-19 Double Pulse Test with

Weak Drive Strength Figure 3-21 Turn-on Waveforms with

Weak Drive Strength

Figure 3-21 Turn-on Waveforms with

Weak Drive Strength Figure 3-23 Turn-off Waveforms with

Strong Drive Strength

Figure 3-23 Turn-off Waveforms with

Strong Drive Strength Figure 3-20 Turn-off Waveforms with

Weak Drive Strength

Figure 3-20 Turn-off Waveforms with

Weak Drive Strength Figure 3-22 Double Pulse Test with

Strong Drive Strength

Figure 3-22 Double Pulse Test with

Strong Drive Strength Figure 3-24 Turn-on Waveforms with

Strong Drive Strength

Figure 3-24 Turn-on Waveforms with

Strong Drive StrengthTable 3-6 Switching Energy

Measurements

| Weak drive (5 A) | Strong drive (15 A) | |

|---|---|---|

| Turn-off energy | 5.65 mJ | 2.77 mJ |

| Turn-on energy | 6.46 mJ | 3.13 mJ |