TIDUF31B May 2023 – September 2024

- 1

- Description

- Resources

- Features

- Applications

- 6

- 1System Description

- 2System Overview

-

3System Design Theory

- 3.1 High-Voltage Buck Auxiliary Power Supply

- 3.2 DC Bus Voltage Sensing

- 3.3 Motor Drive Stage

- 3.4 Bypass Capacitors

- 3.5 Phase Current Sensing With Two or Three Shunt Resistors

- 3.6 Phase Current Sensing With a Single Shunt Resistor

- 3.7 Hall-Effect Sensor or QEI Interface for Sensored Motor Control

- 3.8 DAC for Software Debug

- 3.9 Overcurrent Protection

- 3.10 Overtemperature Protection

- 3.11 Isolated UART port

- 3.12 Inverter Peak Power Capability

- 4Hardware, Software, Testing Requirements, and Test Results

- 5Design and Documentation Support

- 6About the Author

- 7Revision History

4.2.1.4 Download Image and Spin Motor

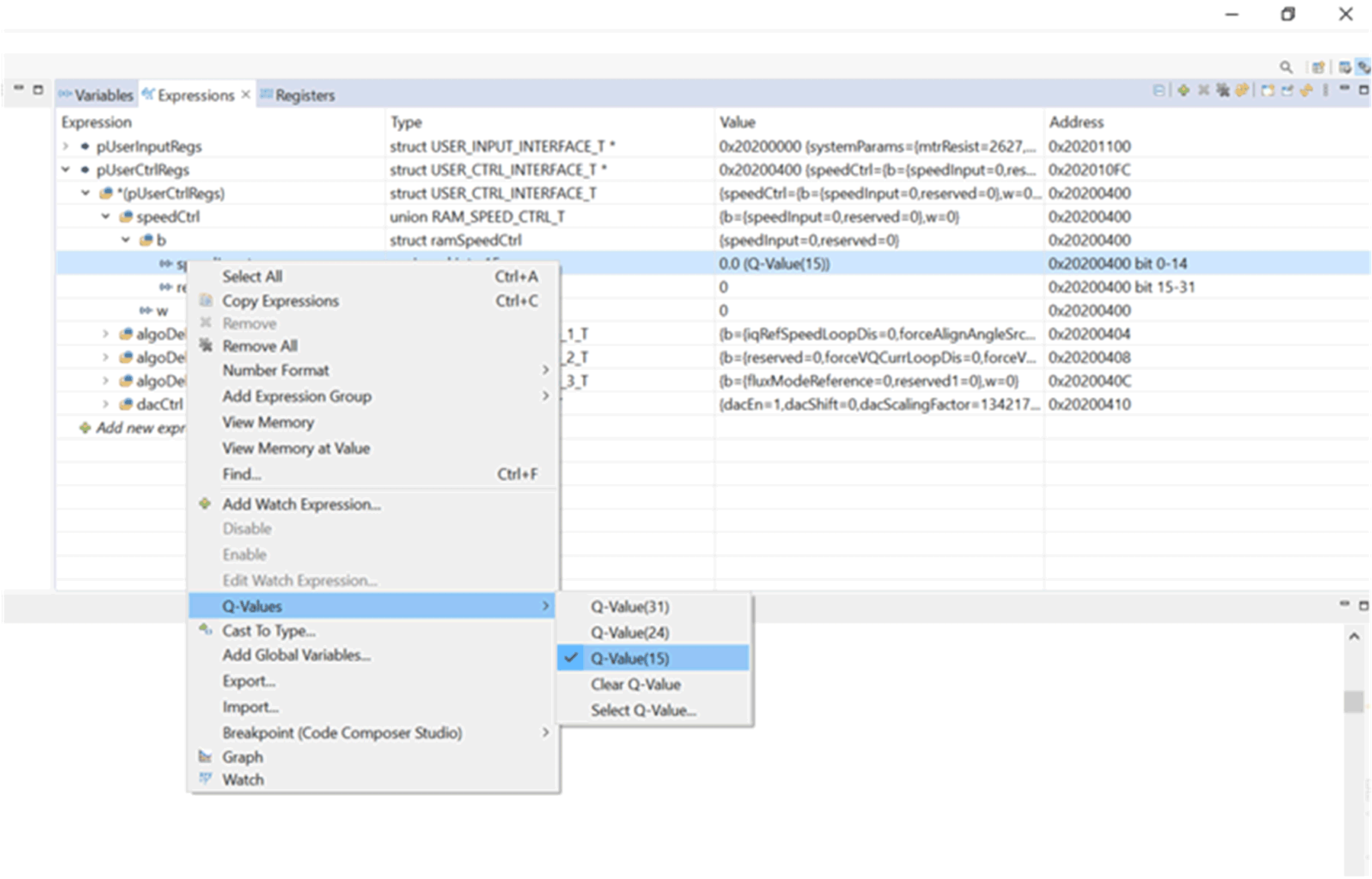

Click the Run → Debug

menu options to download and debug software in CCS, then add

pUserCtrlRegs variables into Expressions windows, Select

pUserCtrlRegs → speedCtrl → b → speedInput, right click, select

Q-Values → Q-Value(15). Figure 4-9 shows where and how to change value type.

Figure 4-9 Download And Debug

Figure 4-9 Download And DebugRun code by clicking the Run

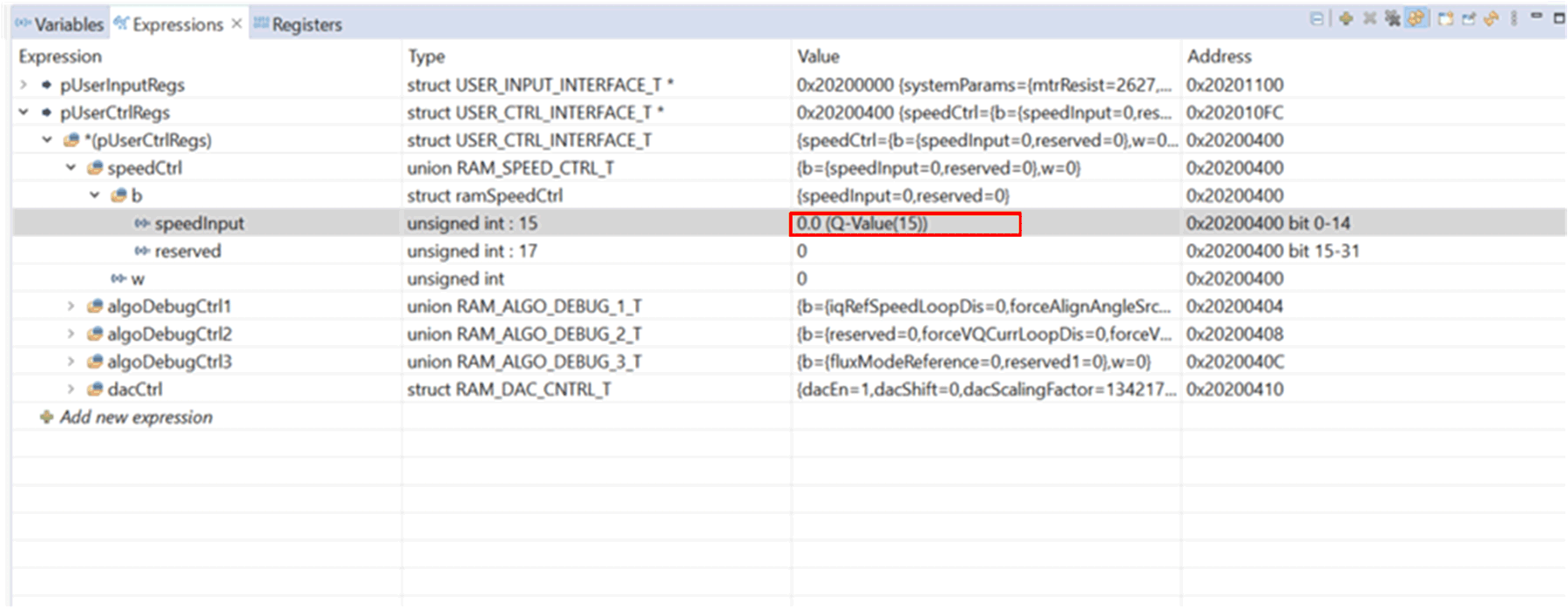

button in CCS, and change the speedInput to a non-zero value to

spin the motor, for example, 0.6, this number is a normalization number of the

maximum speed, so if speedInput = 1, the motor runs at the maximum

speed. To stop the motor, set speedInput to zero.

Figure 4-10 shows where to change the speedInput value.

Figure 4-10 Set Motor Speed Percentage by

Figure 4-10 Set Motor Speed Percentage by

speedInput