TIDUF31B May 2023 – September 2024

- 1

- Description

- Resources

- Features

- Applications

- 6

- 1System Description

- 2System Overview

-

3System Design Theory

- 3.1 High-Voltage Buck Auxiliary Power Supply

- 3.2 DC Bus Voltage Sensing

- 3.3 Motor Drive Stage

- 3.4 Bypass Capacitors

- 3.5 Phase Current Sensing With Two or Three Shunt Resistors

- 3.6 Phase Current Sensing With a Single Shunt Resistor

- 3.7 Hall-Effect Sensor or QEI Interface for Sensored Motor Control

- 3.8 DAC for Software Debug

- 3.9 Overcurrent Protection

- 3.10 Overtemperature Protection

- 3.11 Isolated UART port

- 3.12 Inverter Peak Power Capability

- 4Hardware, Software, Testing Requirements, and Test Results

- 5Design and Documentation Support

- 6About the Author

- 7Revision History

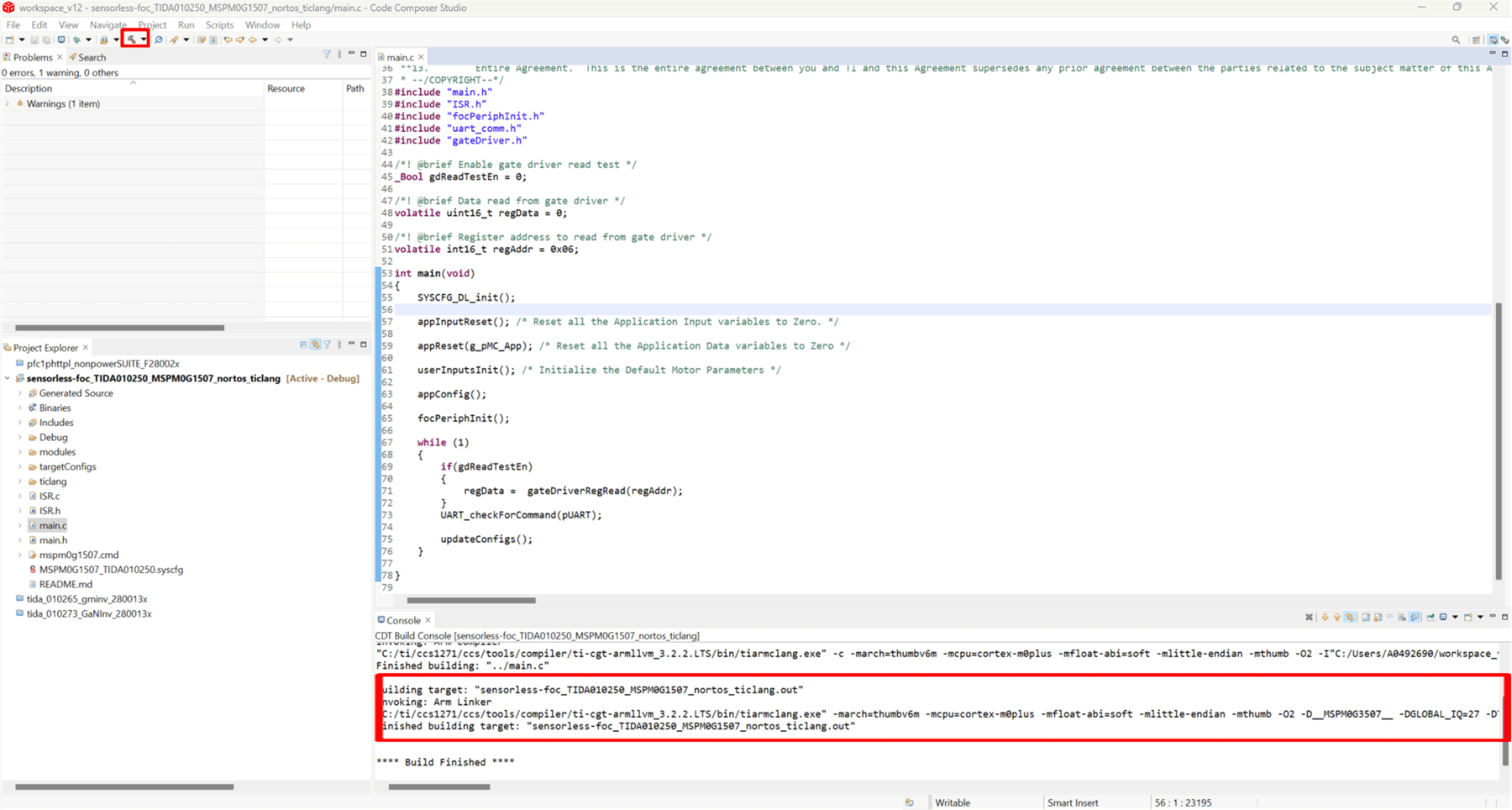

4.2.1.3 Compile the Project

The Sensorless-foc project

for TIDA-010250 is now active. Click the Build button or select the

Project → Build Project menu, the .out file is

now generated after the compilation is finished. Figure 4-5 shows the resulting project build.

Figure 4-5 Build Project

Figure 4-5 Build ProjectNow open the ISR.c file to check

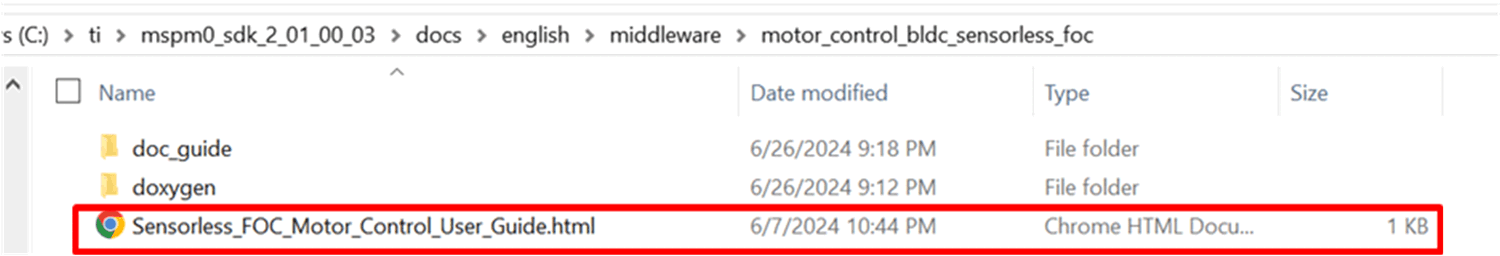

motor parameters, see the register map section in the Sensorless FOC Motor

Control User Guide, this guide is found in the MSPM0 SDK folder:

<install_location>\ti\mspm0_sdk_2_01_00_03\docs\english\middleware\motor_control_bldc_sensorless_foc

Figure 4-6 shows file location.

Figure 4-6 Folder for Sensorless FOC

Motor Control User Guide

Figure 4-6 Folder for Sensorless FOC

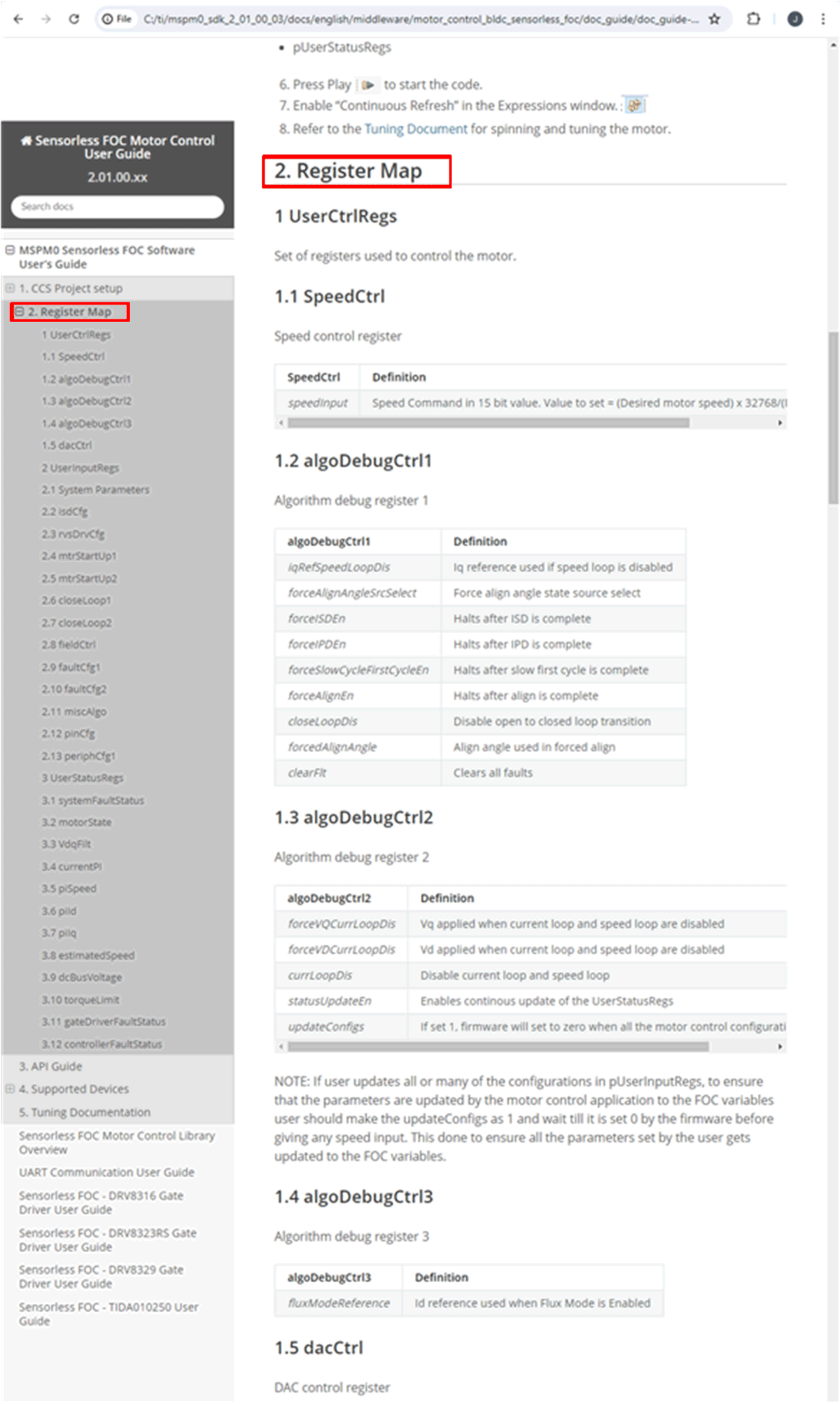

Motor Control User GuideThis design guide introduces all the registers for the FOC algorithm, the designer can also add or remove some special functions of FOC using those registers. Figure 4-7 shows the register map.

Figure 4-7 Register Map

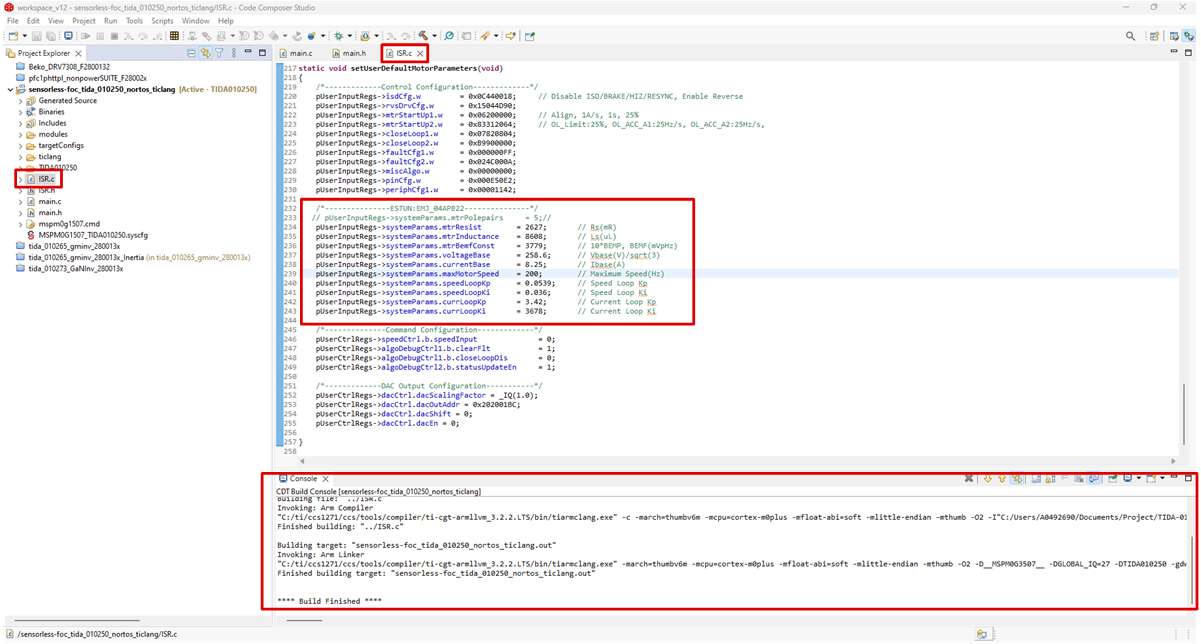

Figure 4-7 Register MapMotor and control parameters are found in

ISR.c, which can be updated per the motor and system of the

user. The parameters for motor EMJ_04APB22,

unit of each parameter are shown below. For more information, see the MSPM0 Sensorless FOC Tuning Guide application

note.

pUserInputRegs->systemParams.mtrResist = 2627; // Rs(mR)

pUserInputRegs->systemParams.mtrInductance = 8608; // Ls(uH)

pUserInputRegs->systemParams.mtrBemfConst = 3779; // 10*BEMP, BEMF(mVpHz)

pUserInputRegs->systemParams.voltageBase = 258.6; // Vbase(V)/sqrt(3)

pUserInputRegs->systemParams.currentBase = 8.25; // Ibase(A)

pUserInputRegs->systemParams.maxMotorSpeed = 200; // Maximum Speed(Hz)

pUserInputRegs->systemParams.speedLoopKp = 0.0539; // Speed Loop Kp

pUserInputRegs->systemParams.speedLoopKi = 0.036; // Speed Loop Ki

pUserInputRegs->systemParams.currLoopKp = 3.42; // Current Loop Kp

pUserInputRegs->systemParams.currLoopKi = 3678; // Current Loop KiAfter update motor and control parameters, click

the Compile button, no error information and the .out file

are created in the Console window, see Figure 4-8.

Figure 4-8 EMJ_04APB22 Motor Parameters

and Compile Results

Figure 4-8 EMJ_04APB22 Motor Parameters

and Compile Results