TIDUF60 December 2023

- 1

- Description

- Resources

- Features

- Applications

- 6

- 1System Description

-

2System Overview

- 2.1 Block Diagram

- 2.2 Design Considerations

- 2.3 Highlighted Products

- 2.4 System Design Theory

-

3Hardware, Software, Testing Requirements, and Test Results

- 3.1 Getting Started Hardware

- 3.2 Getting Started GUI

- 3.3

Getting Started C2000 Firmware

- 3.3.1 Download and Install Software Required for Board Test

- 3.3.2 Opening Project Inside CCS

- 3.3.3 Project Structure

- 3.3.4 Test Procedure

- 3.4 Test Results

- 3.5 Migrate Firmware to a New Hardware Board

- 3.6 Getting Started MSPM0 Firmware

- 4Design and Documentation Support

- 5About the Author

3.4.1 Load and Thermal Test

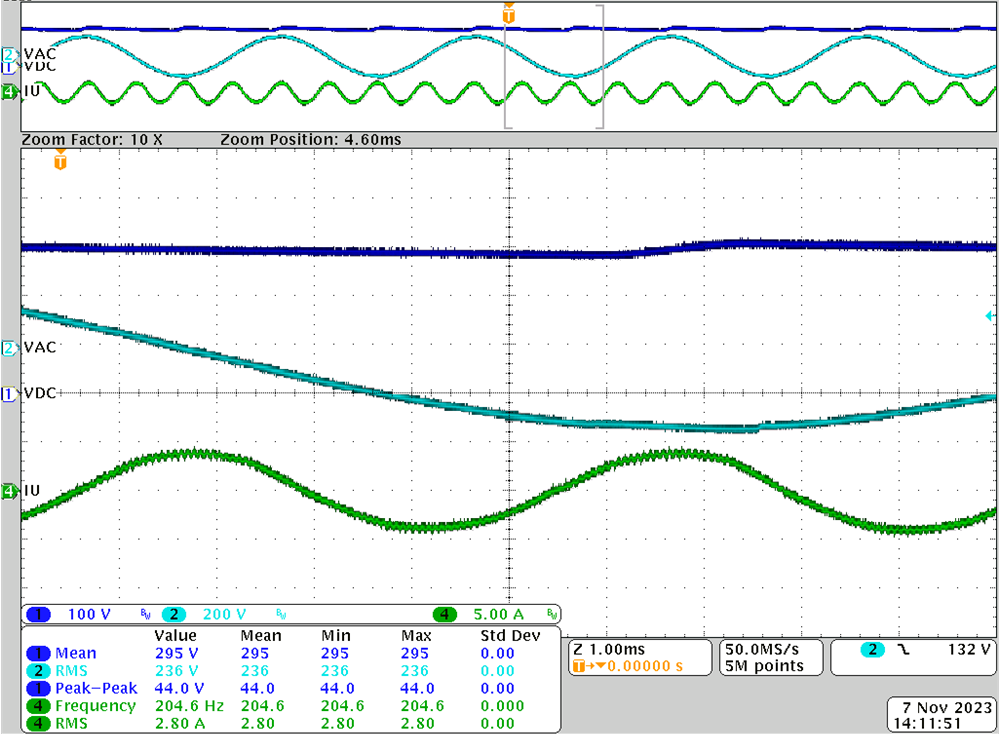

Figure 3-38 is a waveform at 3000 RPM (200 Hz) under 500-W dyno load. The waveform includes the following display:

- CH1 (Blue): DCBUS voltage

- CH2 (Light Blue): AC Input Voltage

- CH4 (Green): Current of phase U

Figure 3-38 Phase Current and Voltage Waveforms of Motor at 500 W, 200 Hz

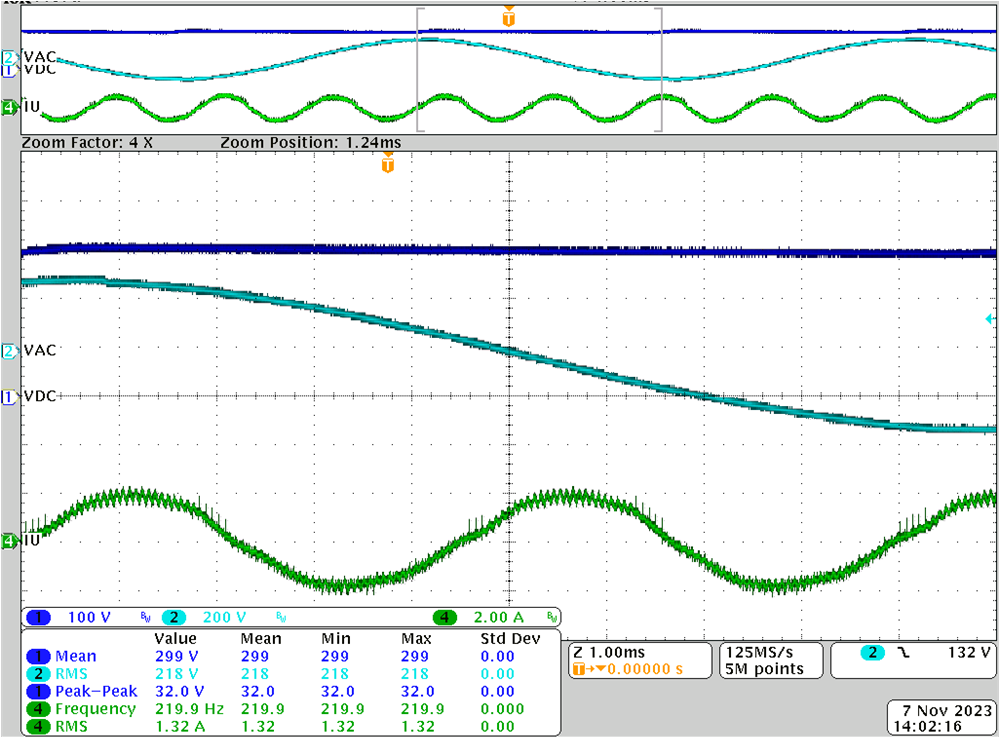

Figure 3-38 Phase Current and Voltage Waveforms of Motor at 500 W, 200 HzFigure 3-38 shows a waveform at 3300 RPM (220 Hz) under 300-W dyno load with field weakening enabled. The motor tested is rated at 3000 RPM (200 Hz) and now works at field-weakening status.

- CH1 (Blue): DCBUS voltage

- CH2 (Light Blue): AC Input Voltage

- CH4 (Green): Current of phase U

Figure 3-39 Field Weakening Test at 300 W, 220 Hz

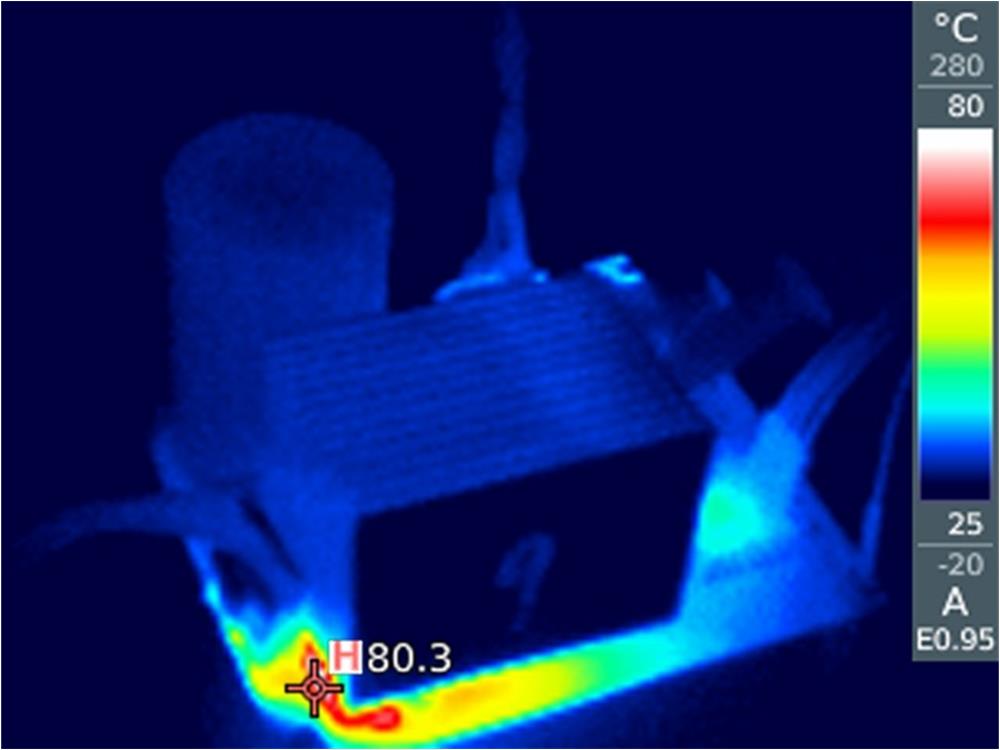

Figure 3-39 Field Weakening Test at 300 W, 220 HzThis board is designed to work at 750 W for a short amount of time (≤ 1 minute), pay attention to rising temperatures. If running the board at high power or for a long time, use an external cooling fan to cool down the heat sink. Figure 3-38 shows the board temperature rising at 500 W, 3000 RPM (200 Hz).

Figure 3-40 Thermal Test Under 220 VAC, 500 W, 200 Hz

Figure 3-40 Thermal Test Under 220 VAC, 500 W, 200 Hz