TIDUF64A December 2023 – August 2024

- 1

- Description

- Resources

- Features

- Applications

- 6

- 1System Description

- 2System Design Theory

-

3System Overview

- 3.1 Block Diagram

- 3.2 Design Considerations

- 3.3

Highlighted Products

- 3.3.1 TMDSCNCD280039C - TMS320F280039C Evaluation Module C2000™ MCU controlCARD™

- 3.3.2 LMG3522R030 650-V 30-mΩ GaN FET With Integrated Driver, Protection and Temperature Reporting

- 3.3.3 TMCS1123 - Precision Hall-Effect Current Sensor

- 3.3.4 AMC1302 - Precision, ±50-mV Input, Reinforced Isolated Amplifier

- 3.3.5 ISO7741 Robust EMC, Quad-channel, 3 Forward, 1 Reverse, Reinforced Digital Isolator

- 3.3.6 ISO7762 Robust EMC, Six-Channel, 4 Forward, 2 Reverse, Reinforced Digital Isolator

- 3.3.7 UCC14131-Q1 Automotive, 1.5-W, 12-V to 15-V VIN, 12-V to 15-V VOUT, High-Density > 5-kVRMS Isolated DC/DC Module

- 3.3.8 ISOW1044 Low-Emissions, 5-kVRMS Isolated CAN FD Transceiver With Integrated DC/DC Power

- 3.3.9 ISOW1412 Low-Emissions, 500kbps, Reinforced Isolated RS-485, RS-422 Transceiver With Integrated Power

- 3.3.10 OPA4388 Quad, 10-MHz, CMOS, Zero-Drift, Zero-Crossover, True RRIO Precision Operational Amplifier

- 3.3.11 OPA2388 Dual, 10-MHz, CMOS, Zero-Drift, Zero-Crossover, True RRIO Precision Operational Amplifier

- 3.3.12 INA181 26-V Bidirectional 350-kHz Current-Sense Amplifier

- 4Hardware, Software, Testing Requirements, and Test Results

- 5Design and Documentation Support

- 6About the Authors

- 7Revision History

4.3.2 Bidirectional DC/DC Stage - Buck-Mode

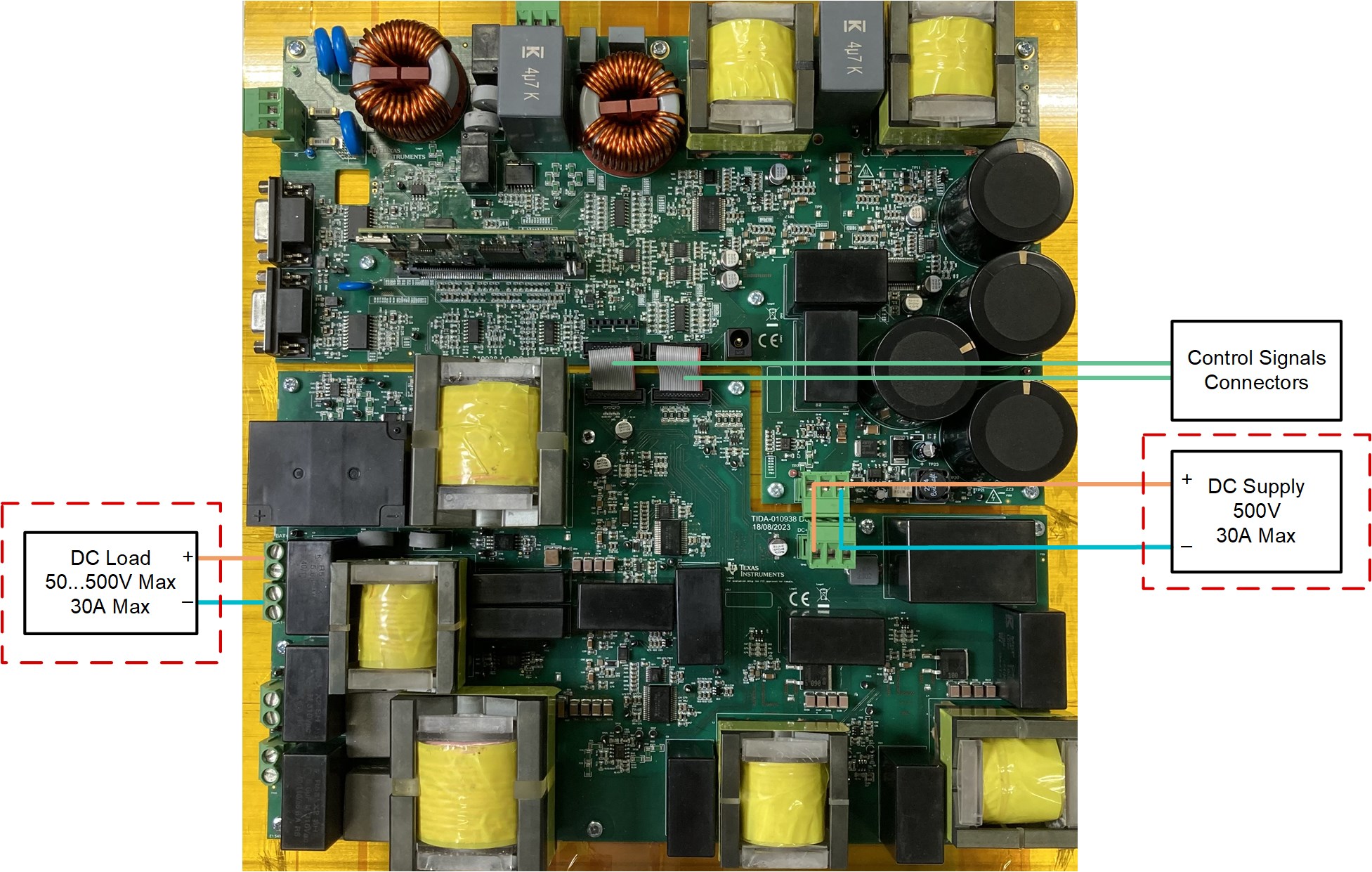

Figure 4-3 shows the connection for the boards. For safety reasons make sure that the proper voltage and current limit is selected on DC power sources. DC load needs to be configured in constant voltage mode with the required voltage and current limits. The DC bus of the DC/DC board is connected to that of DC/AC board, and so are the connectors for the control signals. The DC source needs to be configured in constant-voltage mode with the DC bus voltage of 500V maximum and 30A maximum current.

Figure 4-3 Connections for Testing

Bidirectional DC-DC in Buck-mode

Figure 4-3 Connections for Testing

Bidirectional DC-DC in Buck-mode