TIDUF67 April 2024 – December 2024

- 1

- Description

- Resources

- Features

- Applications

- 6

- 1System Description

- 2System Overview

- 3System Design Theory

-

4Hardware, Software, Testing Requirements,

and Test Results

- 4.1 Hardware Requirements

- 4.2 Software Requirements

- 4.3 Test Setup

- 4.4 Test Results

- 4.5 Adding Additional Functionality to Motor Control Project

- 4.6 Building a Custom Board

- 5General Texas Instruments High Voltage Evaluation (TI HV EVM) User Safety Guidelines

- 6Design and Documentation Support

- 7About the Author

4.6.1.2.6 Configuring the CMPSS Module

The CMPSS module is used for overcurrent monitoring for the phase currents. A threshold is set using the CMPSS DAC, and if the output of the current sense amplifier exceeds that threshold then the CMPSS output trips.

If using a custom motor driver board, or migrating the code to a TI MCU or a TI motor driver EVM that is not supported with the current Universal Motor Control Project, then the connections between the ADC pins and the CMPSS modules need to be properly modified in the .syscfg file based on the motor driver and TI MCU connections. For more details on the internal connections of the CMPSS module, see the ADC Signal Descriptions tables in the AM263x Sitara™ Microcontrollers data sheet.

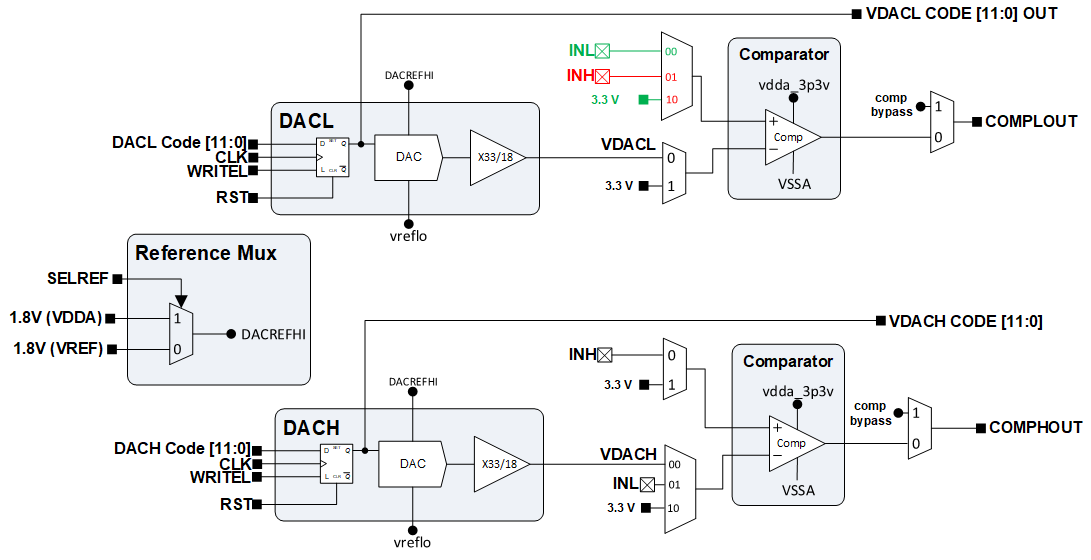

The .syscfg file configures the CMPSS modules according to the motor driver board that is used. For example, the diagram of the connections between the LP-AM263 and BOOSTXL-3PHGANINV are shown in Figure 4-55. Figure 4-56 shows the CMPSSA block diagram. CMPSSA has the additional support of INH and INL as a muxable input for the COMPL positive signal.

Figure 4-55 CMPSS Connection

Diagram

Figure 4-55 CMPSS Connection

Diagram Figure 4-56 CMPSSA Block Diagram

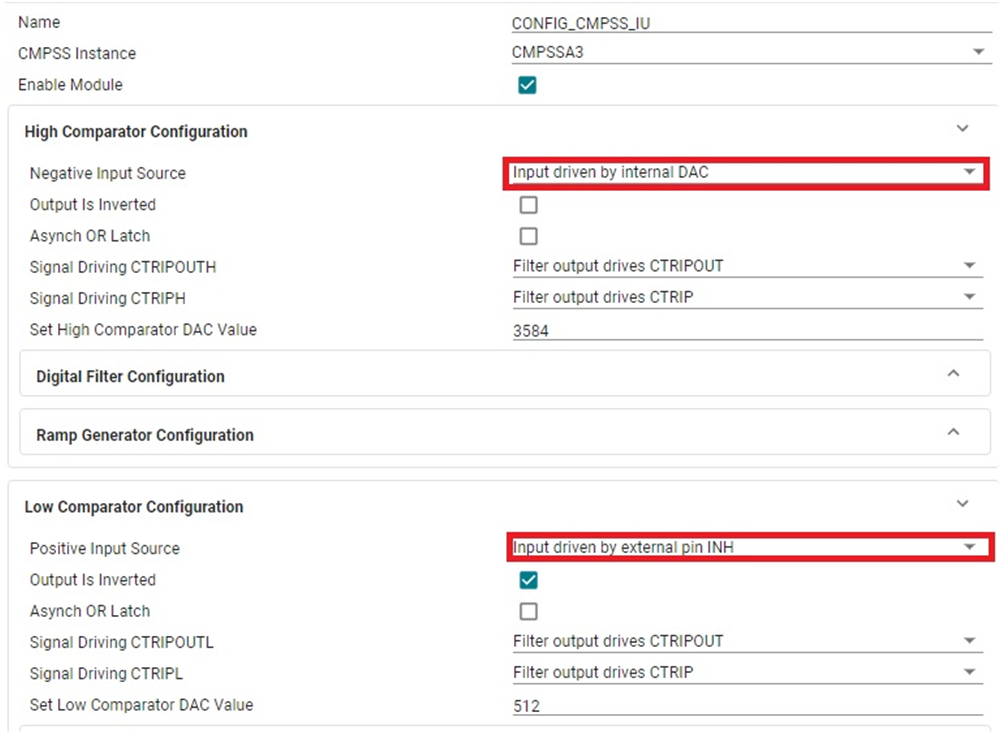

Figure 4-56 CMPSSA Block DiagramEach CMPSS comparator has a high and low comparator, so the signals must be muxed appropriately to the desired input of the desired comparator. For more information on these connections, please refer to the Analog Pins and internal connections table in the data sheet of the microcontroller that is being used. Figure 4-57 shows the CMPSS comparator configuration for the LP-AM263 and BOOSTXL-3PHGANINV combination to do window comparison for phase currents. DAC values are updated in the code based on the defined maximum current. Note that for AM263x devices, the ADCx_AIN1 and ADCx_AIN3 are only connected to the (INL) which results limitation for both positive and negative overcurrent trips. For TMDSHVMTRINSPIN and TMDSCNCD263 combination, the ADC used for U-pahse current measurement are connected to ADC1_AIN3.

Also, please note that to select the right voltage reference in Launch Pad or EVM Control Card matching the DAC Reference Voltage. For example, in AM263x LaunchPad, use DAC VREF Switch (S1) to choose AM263x on-die LDO.

Figure 4-57 CMPSS Comparator

Configuration

Figure 4-57 CMPSS Comparator

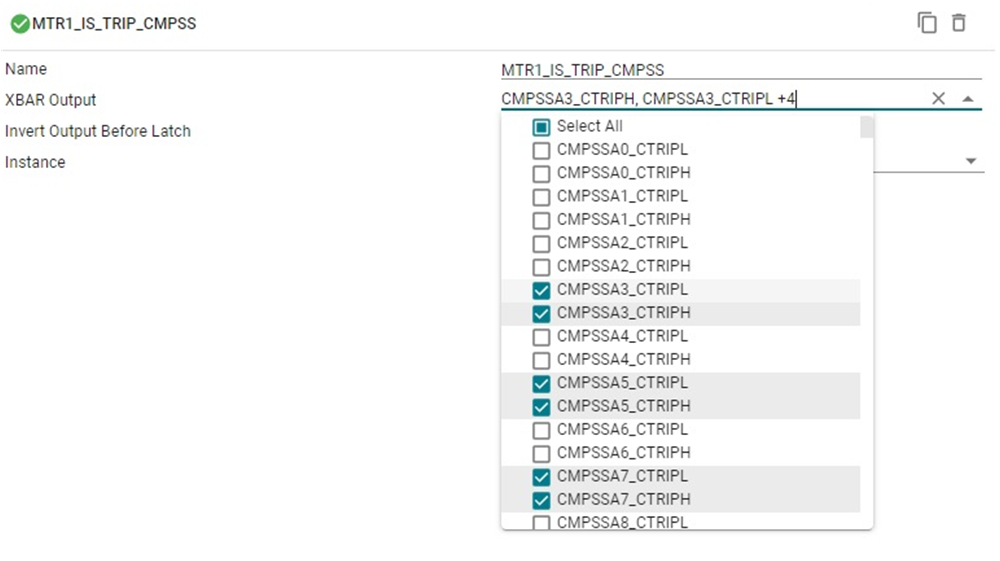

ConfigurationFigure 4-58 shows the selecting corresponding CMPSS CTRIPL and CTRIPH for the EPWM XABR to generate trip in the event of overcurrent and undercurrent.

Figure 4-58 EPWM XBAR

Configuration

Figure 4-58 EPWM XBAR

Configuration