TIDUF67 April 2024 – December 2024

- 1

- Description

- Resources

- Features

- Applications

- 6

- 1System Description

- 2System Overview

- 3System Design Theory

-

4Hardware, Software, Testing Requirements,

and Test Results

- 4.1 Hardware Requirements

- 4.2 Software Requirements

- 4.3 Test Setup

- 4.4 Test Results

- 4.5 Adding Additional Functionality to Motor Control Project

- 4.6 Building a Custom Board

- 5General Texas Instruments High Voltage Evaluation (TI HV EVM) User Safety Guidelines

- 6Design and Documentation Support

- 7About the Author

4.4.2.3 Run the Code

- Power on the appropriate power supply, and gradually increase the output voltage of the power supply to get an appropriate DC-bus voltage.

- If using the graph tool, level 2 uses the same graph configurations and parameters as lab 1 to monitor 2 of the phase currents.

- Disable the data cache by unchecking the Data Cache Enabled in Tools > ARM Advanced Features.

- Run the project by clicking on the Resume button, or click Run → Resume in the Debug tab. The systemVars.flagEnableSystem is set to 1 after a fixed time, that means the offsets calibration has completed. The fault flags, motorVars_M1.faultMtrUse.all is equal to 0. If this is not the case, the user must double check the current and voltage sensing circuit in level 1 as described in Section 4.4.1.3. Also, if the moduleOverCurrent in motorVars_M1.faultMtrPrev.bit is 1, then motorSetVars_M1.overCurrent_A needs to be set to higher value to avoid initial high current fault.

- To verify the current and voltage sensing

circuits of the motor driver, set the variable

motorVars_M1.flagEnableRunAndIdentify to 1 in the Expressions window as

shown in Figure 4-16. The motor runs with voltage/frequency (v/f) open loop. If the motor does not spin

smoothly, tune the v/f profile parameters in the user_mtr1.h file as shown in the

following according to the specification of the motor. Note: modification of these

parameters requires rebuilding the project. See step 15 of Section 4.4.1.3 for more information on rebuilding the project in debug mode.

#define USER_MOTOR1_FREQ_LOW_HZ (5.0) // Hz #define USER_MOTOR1_FREQ_HIGH_HZ (400.0) // Hz #define USER_MOTOR1_VOLT_MIN_V (1.0) // Volt #define USER_MOTOR1_VOLT_MAX_V (24.0) // Volt - The motorVars_M1.speedRef_Hz variable is used to set the speed reference for the motor. Check the value of the motorVars_M1.speed_Hz variable in the Expressions window to maintain that the motor speed (motorVars_M1.speed_Hz) is close to the reference speed (motorVars_M1.speedRef_Hz) as shown in Figure 4-16.

- In this build level, the current sensing, voltage sensing, rotor angle estimator, and generator need to be validated. This can be done using the PWMDAC in HV motor kit as described in Section 4.5.2. Additionally, the DATALOG module can be used to view these sensing waveforms. For more information on using the DATALOG to view the currents, voltages, and angle signals, see step 8.

- If using the DATALOG module with the graph tool

to check the current sensing signals, voltage sensing signals, and the angle outputs,

follow the steps described in the following. For more info on the datalog module, see

Section 4.5.1. Note:You must rebuild the project in between each of the following steps after

modifying the code.

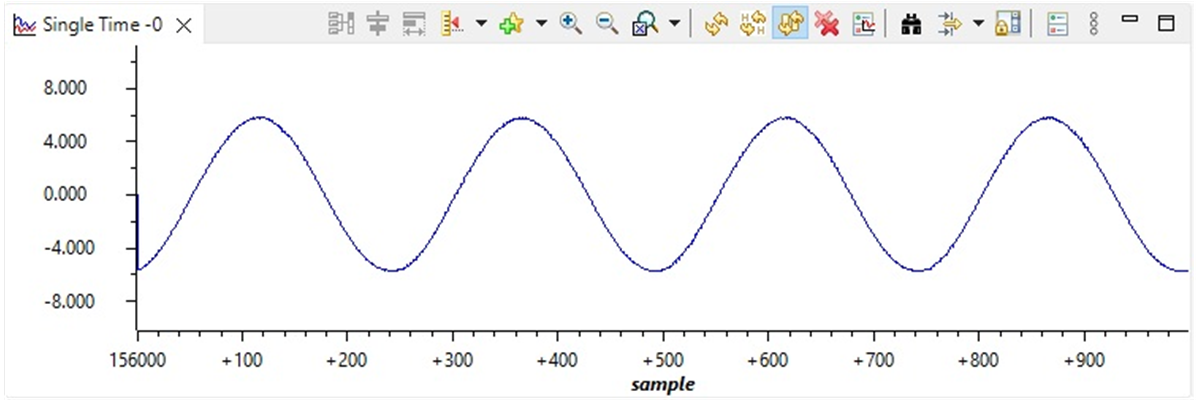

- To test the phase currents using the

DATALOG module, the following code must be set up in the sys_main.c file. Note:

this code is already configured by default for build level 2. The phase current

sampling signals waveform displayed on the graph tool as shown in Figure 4-18.

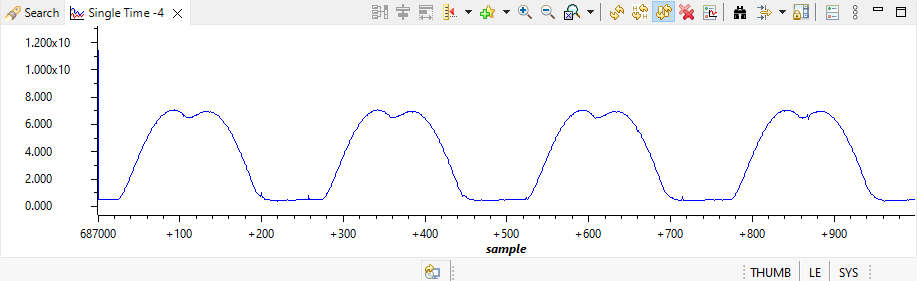

datalogObj->iptr[0] = (float32_t*) &motorVars_M1.adcData.I_A.value[0]; datalogObj->iptr[1] = (float32_t*) &motorVars_M1.adcData.I_A.value[1]; - To test the phase voltage using the

DATALOG module, the following code must be set up in the sys_main.c file. The

phase voltage sampling signals waveform displayed on graph tool as shown in Figure 4-19.

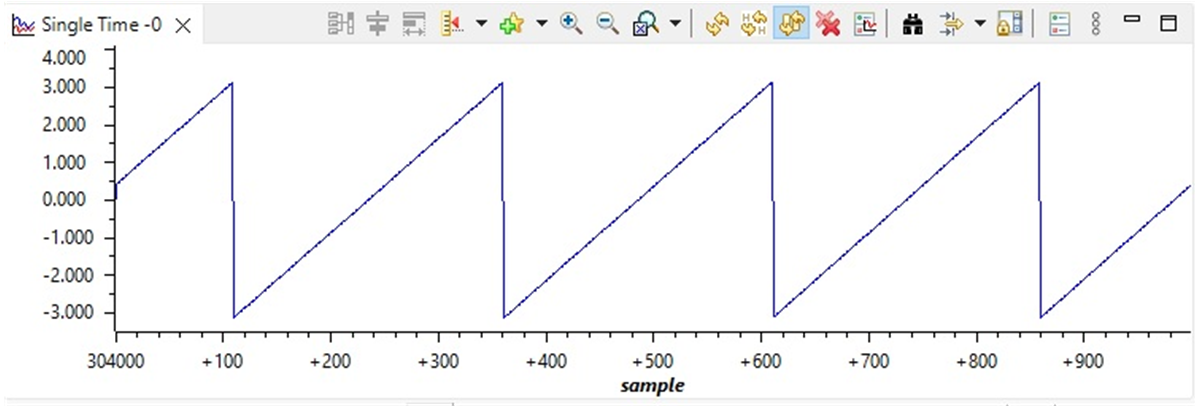

datalogObj->iptr[2] = (float32_t*) &motorVars_M1.adcData.V_V.value[0]; - The angle from the force angle

generator or estimator can be monitored on the graph tool as shown in Figure 4-21. Notice that the angle of the force angle generator is very similar as the

estimated rotor angle of the eSMO

estimator.

datalogObj->iptr[3] = (float32_t*) &motorVars_M1.angleFOC_rad;

- To test the phase currents using the

DATALOG module, the following code must be set up in the sys_main.c file. Note:

this code is already configured by default for build level 2. The phase current

sampling signals waveform displayed on the graph tool as shown in Figure 4-18.

- Verify the over current fault protection by decreasing the value of the variable motorVars_M1.overCurrent_A, the over current protection is implemented by the CMPSS modules. The over current fault triggers if the motorVars_M1.overCurrent_A is set to a value less than the motor phase current actual value, the PWM output is disabled, the motorVars_M1.flagEnableRunAndIdentify is cleared to 0, as shown in Figure 4-17.

- Set the variables motorVars_M1.flagEnableRunAndIdentify to 0 to stop run the motor.

- Once complete, the controller can now be halted, and the debug connection terminated. Fully halting the controller by first clicking the Halt button on the toolbar Suspend or by clicking Target → Halt. Finally, reset the controller by clicking on CPU Reset or clicking Run → Reset.

- Close CCS debug session by clicking on Terminate Debug Session button or clicking Run → Terminate.

- Power off the power supply to the inverter kit.

Figure 4-16 Build Level 2: Variables in

Expressions Window

Figure 4-16 Build Level 2: Variables in

Expressions WindowAdjust the value of motorVars_M1.overCurrent_A in Expression window to trigger the over current fault as shown in Figure 4-17.

Figure 4-17 Build Level 2: Current Protection

Setting

Figure 4-17 Build Level 2: Current Protection

SettingUse Datalog with Graph Tool to monitor three phase sensing current of the motor as shown in Figure 4-18.

Figure 4-18 Build Level 2: Motor Phase Current

Waveforms with Graph Tool

Figure 4-18 Build Level 2: Motor Phase Current

Waveforms with Graph ToolUse Datalog with Graph Tool to monitor three phase sensing voltage of the motor as shown in Figure 4-19. The SVM mode selected here is DPWM with minimum modulation.

Figure 4-19 Build Level 2: Motor Phase Voltage

Waveforms with Graph Tool - DPWM Minimum

Figure 4-19 Build Level 2: Motor Phase Voltage

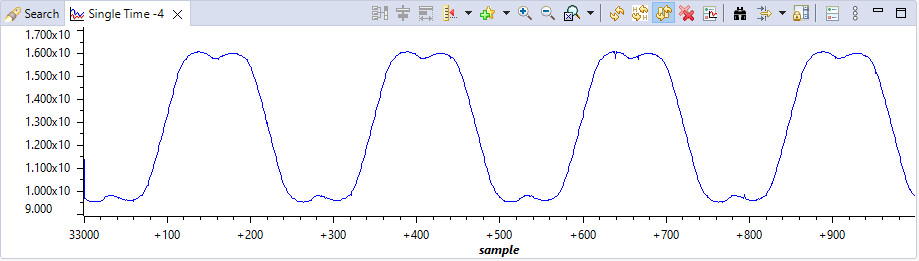

Waveforms with Graph Tool - DPWM MinimumUse Datalog with Graph Tool to monitor three phase sensing voltage of the motor with SVPWM Common modulation as shown in Figure 4-20. SVM type can be selected in motor1_drive.c file.

Figure 4-20 Build Level 2: Motor Phase Voltage Waveforms with Graph Tool - SVPWM Common

Figure 4-20 Build Level 2: Motor Phase Voltage Waveforms with Graph Tool - SVPWM CommonUse Datalog with Graph Tool to monitor rotor angle of the motor from the angle generator and angle from the eSMO estimator as shown in Figure 4-21.

Figure 4-21 Build Level 2: Motor Rotor Angle

Waveforms With Graph Tool

Figure 4-21 Build Level 2: Motor Rotor Angle

Waveforms With Graph Tool