TIDUF68 February 2024

- 1

- Description

- Resources

- Features

- Applications

- 6

- 1System Description

- 2System Overview

- 3System Design Theory

- 4Hardware, Software, Testing Requirements, and Test Results

- 5Design and Documentation Support

- 6About the Author

- 7Recognition

3.5.1 48V to 5V DC/DC Converter

The DC/DC buck converter was designed for an input voltage range from 12V to 60V with at least 80V input voltage capability. The output voltage was set to 5V. The DC/DC buck converter feedback circuit was designed for minimum output voltage ripple and at least 1A output current.

The power supply was entirely designed using WEBENCH® circuit design and selection simulation services, using the following parameter specifications:

| PARAMETER | TYPICAL VALUE | MIN, MAX VALUE |

|---|---|---|

| DC-link voltage | 48V | 10V, 80V |

| Output voltage | 5V | ±5% |

| Output voltage ripple | < 50mVPP | As low as possible |

| Output current | 500mA | 1A |

| Temperature range | –40°C to 85°C (125°C) |

With these parameters the LMR38010 was the device chosen to fit the design specification. Figure 3-7 shows the WEBENCH recommendation.

Figure 3-7 LMR38010 WEBENCH Simulation Circuit

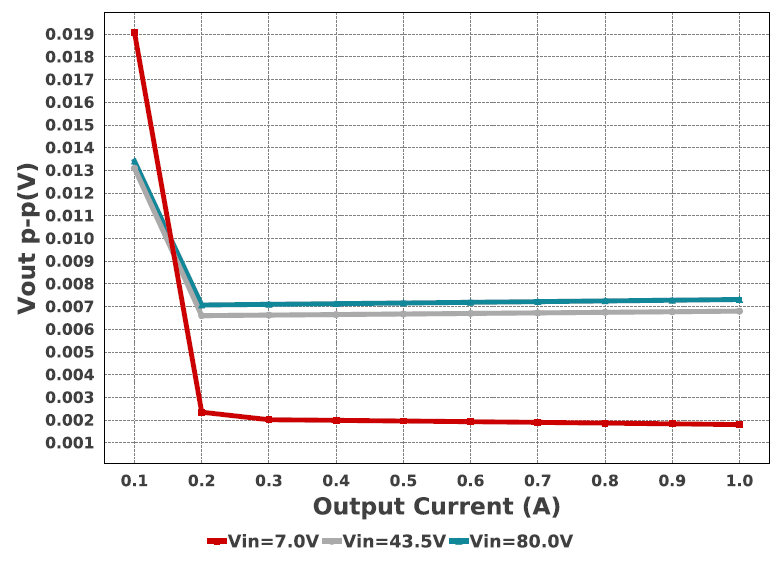

To reduce the size as much as possible, the switching frequency is set to 617kHz (Rt = 42.2kHz), which only requires a 22μH inductor. The voltage ripple is shown in Figure 3-8, for 43.5V input. The output ripple is less than 15mV when the current is >0.1A.

Figure 3-8 5V Output Voltage Ripple

Based on this simulation, some small changes were made to finish the final schematic of this design. Add an optional resistor R68 parallel to R71 to keep the flexibility for the 5.5V output for LDO to generate a lower ripple 5V. The 5.5V can also be input externally through J7.

Figure 3-9 48V to 5V DC/DC Buck Converter