TIDUF74A April 2024 – April 2024

3.1 Hardware Requirements

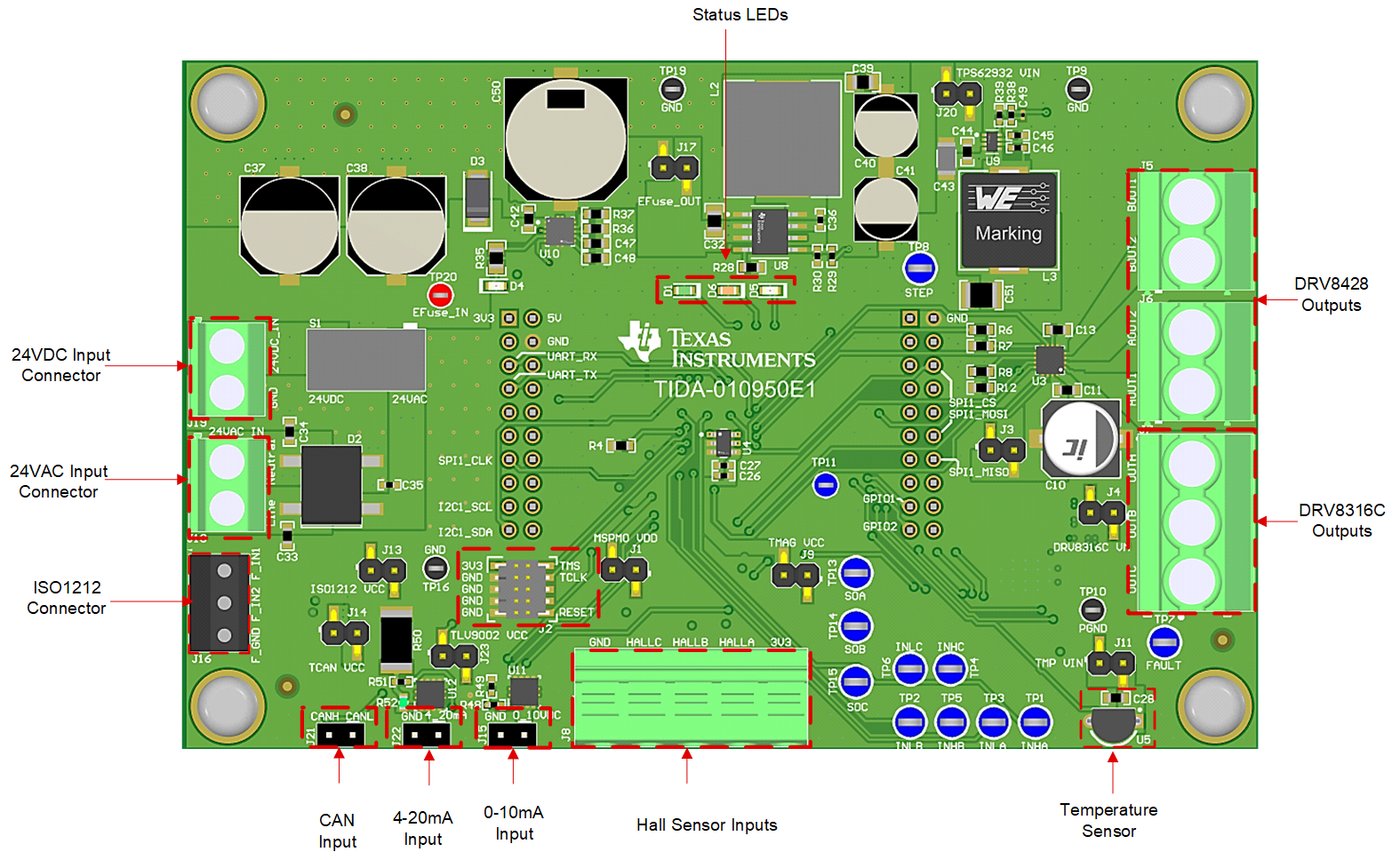

Figure 3-1 below shows the main interface connections for this reference design.

- The power can be switched from 24VAC to 24VDC or completely off based on the position of S1. This allows for flexibility with respect to the input power source while retaining the same functionality for devices down the line from the main power source. The 24VDC is connected via J19, and the 24VAC is connected via J18.

- J16 provides the connection for field inputs to the ISO1212 as well as the field ground.

- J21 is the connection point for the CAN interface.

- J22 is the connection point for the 4-10mA control input front-end. These pins must not be shorted with a jumper during evaluation.

- J15 is the connection point for the 0-10V control input front-end. These pins must not be shorted with a jumper during evaluation.

- J2 is the JTAG connector for deploying firmware to the embedded MSPM0.

- J8 provides the connection of the BLDC motor hall effect sensors to the MCU. A 3.3V connection and GND are also included in this connector for powering the Hall sensors.

- The J5, J6, and J7 srew terminal connectors are the output connections for the BLDC and stepper motor. J5 (BOUT) and J6 (AOUT) connect to the stepper motor, and J7 connects to the 3 phases of the BLDC motor.

There are also 4 LEDs on the board which indicate status:

- D4 – E-Fuse fault indication

- D1 – Damper position correct

- D5 – Error or motor drive fault

- D6 – Damper positional adjustment in progress

Figure 3-1 TIDA-010950 PCB

Connections

Figure 3-1 TIDA-010950 PCB

Connections