TIDUF77 June 2024 – December 2024 MSPM0G1507

- 1

- Description

- Resources

- Features

- Applications

- 6

- 1System Description

-

2System Overview

- 2.1 Block Diagram

- 2.2 Design Considerations

- 2.3 Highlighted Products

- 2.4

System Design Theory

- 2.4.1

Hardware Design

- 2.4.1.1 Modular Design

- 2.4.1.2 Auxiliary Flyback Power Supply

- 2.4.1.3 DC Link Voltage Sensing

- 2.4.1.4 Inrush Current Protection

- 2.4.1.5 Motor Phase Voltage Sensing

- 2.4.1.6 Motor Phase Current Sensing

- 2.4.1.7 Over Current Protection of DRV7308

- 2.4.1.8 Internal Overcurrent Protection for TMS320F2800F137

- 2.4.2 Three-Phase PMSM Drive

- 2.4.1

Hardware Design

-

3Hardware, Software, Testing Requirements, and Test Results

- 3.1 Getting Started Hardware

- 3.2 Getting Started GUI

- 3.3

Getting Started C2000 Firmware

- 3.3.1 Download and Install Software Required for Board Test

- 3.3.2 Opening Project Inside CCS

- 3.3.3 Project Structure

- 3.3.4 Test Procedure

- 3.4

Test Results

- 3.4.1 Fast and clean Rising/Falling Edge

- 3.4.2 Inrush Current Protection

- 3.4.3 Thermal performance under 300VDC

- 3.4.4 Thermal performance under 220VAC

- 3.4.5 Overcurrent Protection by Internal CMPSS

- 3.4.6 IPM Efficiency with External Bias Supply under 300VDC

- 3.4.7 Board Efficiency with Onboard Bias Supply under 300VDC

- 3.4.8 Board Efficiency with External Bias Supply under 220VAC

- 3.4.9 Board Efficiency with Onboard Bias Supply under 220VAC

- 3.4.10 iTHD Test of Motor Phase Current

- 3.4.11 Standby Power Test

- 3.5 Migrate Firmware to a New Hardware Board

- 3.6 Getting Started MSPM0 Firmware

- 4Design and Documentation Support

- 5About the Author

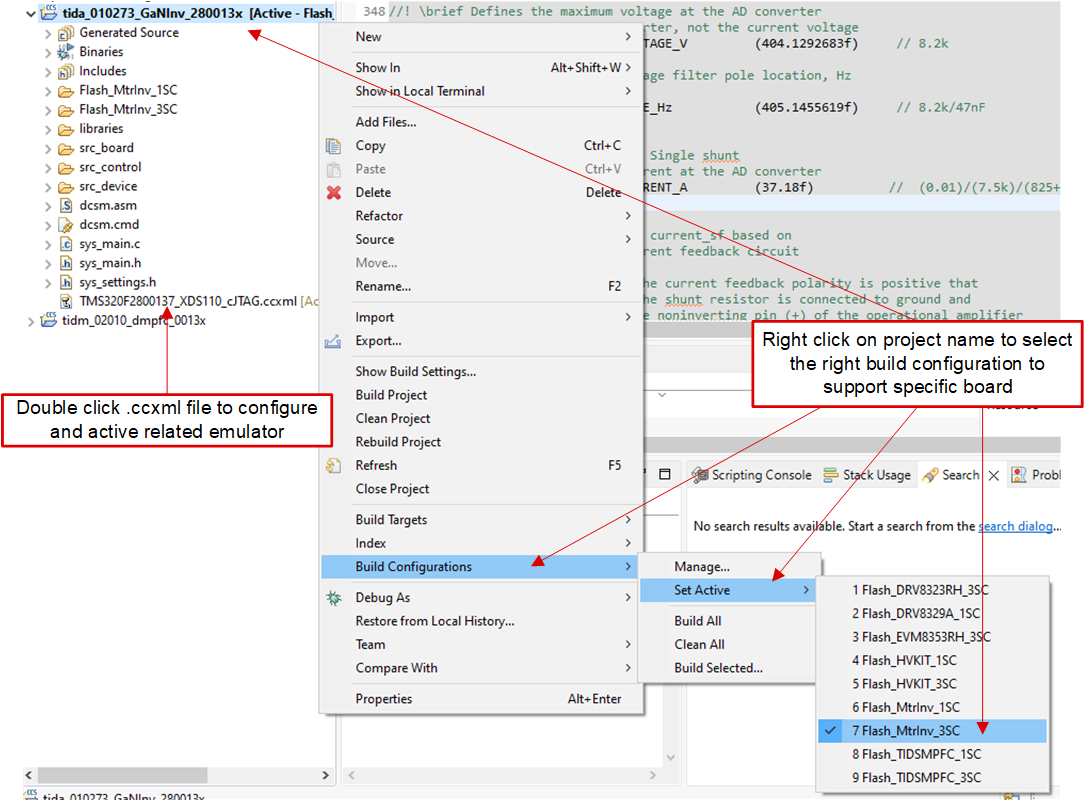

3.3.2 Opening Project Inside CCS

<install_location>\solutions\tida_010273_GaNInv\f280013x\ccs\motor_controlImport the project within CCS and select the right build configurations by right-clicking on project name as shown in Figure 3-18. Select the right build configuration for the HVAC reference design. The Flash_MtrInv_3SC build configuration supports the three-shunt current sensing method, Flash_MtrInv_1SC supports the single-shunt current sensing method.

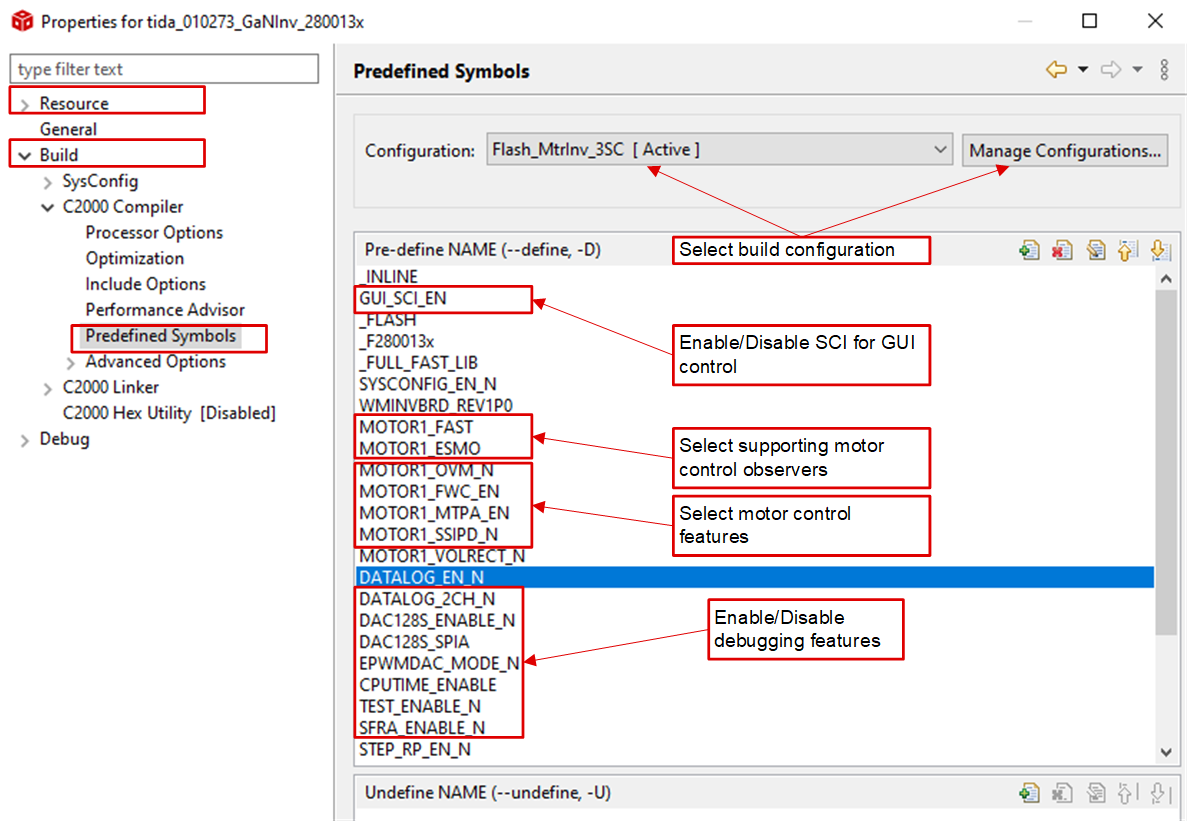

Configure the project

to select the supporting functions in the project by clicking Project →

Import CCS Projects, and browse to

<install_location>\solutions\

for F280013x based reference design, and then right-click on the imported project

name, click Properties command to set the pre-define symbols for the project

as shown in Figure 3-19.tida_010273_GaNInv\f280013x\ccs\motor_control

Figure 3-18 Select the Correct Build

Configuration

Figure 3-18 Select the Correct Build

Configuration Figure 3-19 Select the Correct Predefined

Symbols in Project Properties

Figure 3-19 Select the Correct Predefined

Symbols in Project Properties