TIDUFB1 December 2024

- 1

- Description

- Resources

- Features

- Applications

- 6

- 1System Description

-

2System Overview

- 2.1 Block Diagram

- 2.2 Design Considerations

- 2.3 Highlighted Products

- 2.4

Hardware Design

- 2.4.1 Inductor Design

- 2.4.2 Bus Capacitor Selection

- 2.4.3 Input AC Voltage Sensing

- 2.4.4 Output DCBUS Voltage Sensing

- 2.4.5 Auxiliary Power Supply

- 2.4.6 Isolated Power Supply

- 2.4.7 Inductor Current Sensing

- 2.4.8 Gate Driver

- 2.4.9 Isolated Temperature Sensing

- 2.4.10 Overcurrent, Overvoltage Protection (CMPSS)

-

3Hardware, Software, Testing Requirements, and Test Results

- 3.1 Hardware Requirements

- 3.2

Software Requirements

- 3.2.1 Getting Started GUI

- 3.2.2

Getting Started Firmware

- 3.2.2.1 Opening the Project Inside Code Composer Studio™

- 3.2.2.2 Project Structure

- 3.2.2.3 Test Setup

- 3.2.2.4 Running Project

- 3.3

Test Results

- 3.3.1 IGBT Gate Rising and Falling Time

- 3.3.2 Power On Sequence

- 3.3.3 PFC Started by GUI

- 3.3.4 Zero Crossing Under 380VAC, 9kW

- 3.3.5 Current Ripple Under 380VAC,10kW

- 3.3.6 10kW Load Test With Grid Power

- 3.3.7 9kW Load Test With AC Power Source

- 3.3.8 Power Analyzer Results

- 3.3.9 Thermal Performance

- 3.3.10 Voltage Short Interrupt Test

- 3.3.11 Efficiency, iTHD, and Power Factor Results

- 4Design and Documentation Support

- 5About the Author

3.2.2.4.1.4 Running Code (Build 1)

- Run the project by clicking the

button.

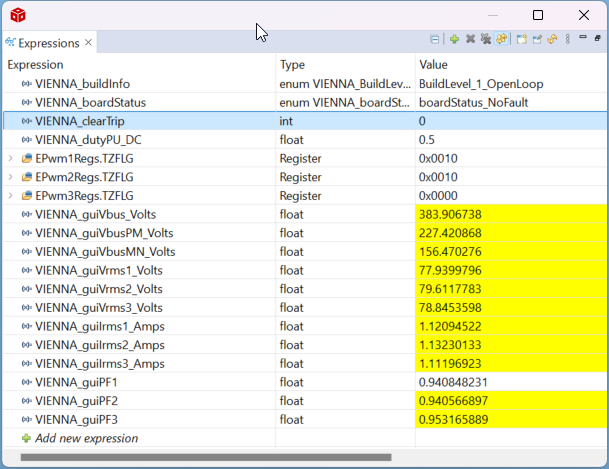

button. - In the watch view, periodically check if the

guiVbus(VIENNA_guiVbus_Voltsin the Expression window) variable is updating. If there is no change in the value, then make sure the real-time mode is enabled, and the hardware is set up correctly. Do not proceed further unless the update is verified.Note: As no power is applied right now, this value is close to zero. - Slowly increase the input AC voltage from 0VRMS to 80VRMS L-N.

- Verify the voltage sensing: Make sure

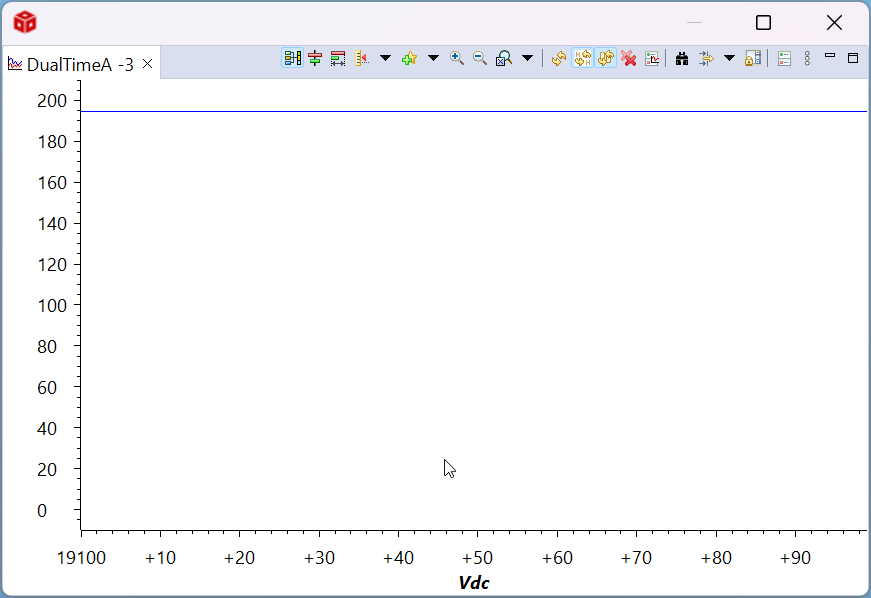

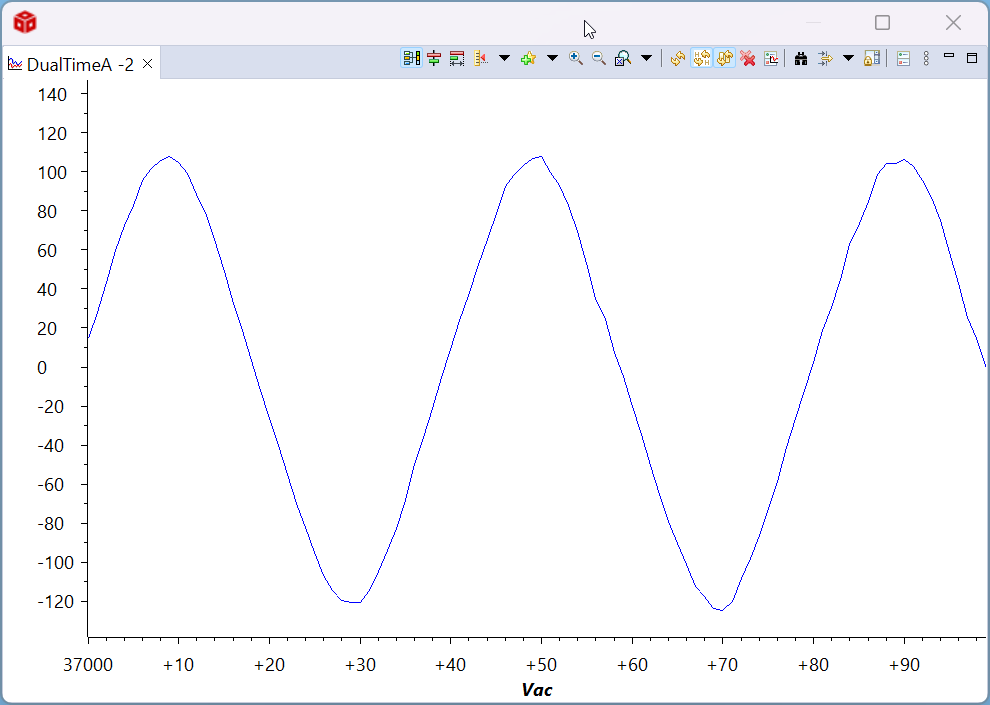

guiVbus,guiVbusPM, andguiVbusMNdisplay the correct values. For the 80VRMS L-N,guiVbusis close to 190V, the graph function can show the waveform, as shown in Figure 3-10. TheguiVbusPMandguiVbusMNvariables are both close to 85V. The code runs a sine analyzer module, which computes the RMS value of the voltage and current. Figure 3-11 shows that theguiVrms1,guiVrms2andguiVrms3values are close to the input value, that is, 80VRMS. This verifies the voltage sensing of the board. Figure 3-10 Build Level 1: Graph Showing Measured Output Voltages

Figure 3-10 Build Level 1: Graph Showing Measured Output Voltages Figure 3-11 Build Level 1: Graph Showing Measured Input Voltages

Figure 3-11 Build Level 1: Graph Showing Measured Input Voltages - Verifying the current sensing: Notice the

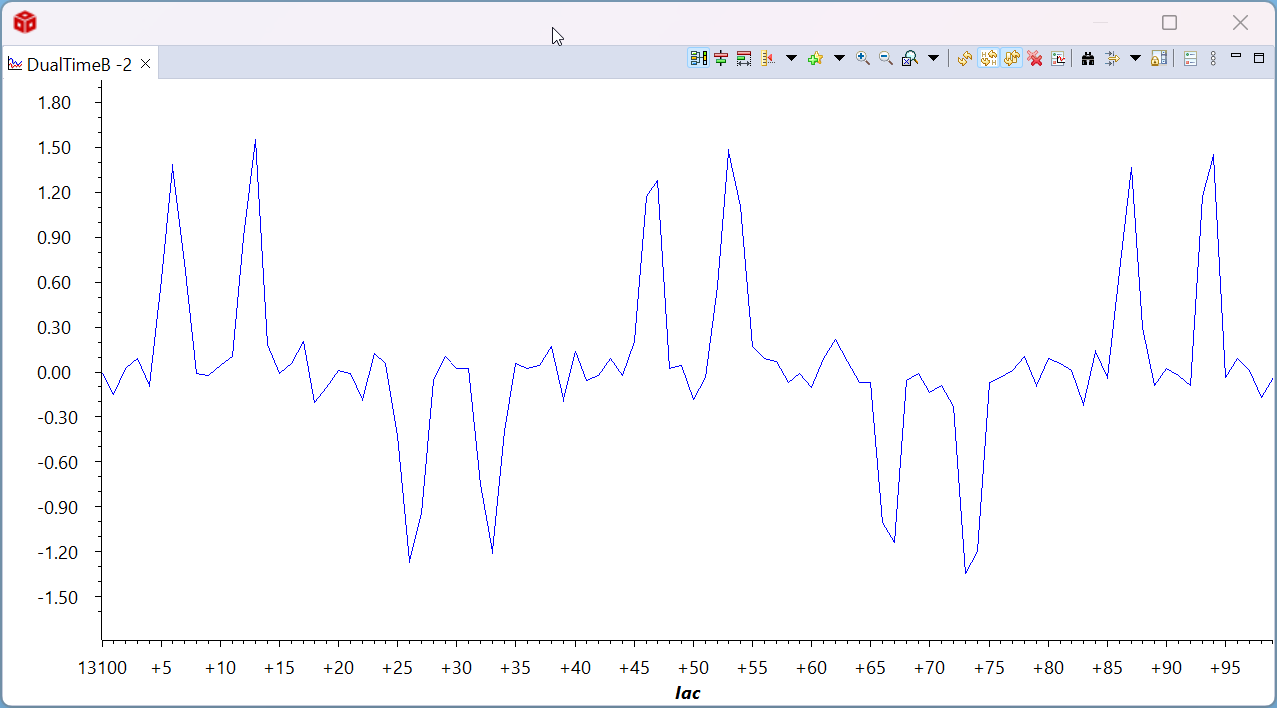

guiVrms1,guiVrms2, andguiVrms3variables, for the given test condition these values are close to 0.5A. Additionally, the graphs must be seen to verify the current measurement. Figure 3-12 shows the currents on a graph. Figure 3-12 Build Level 1: Graph Showing Measured Currents

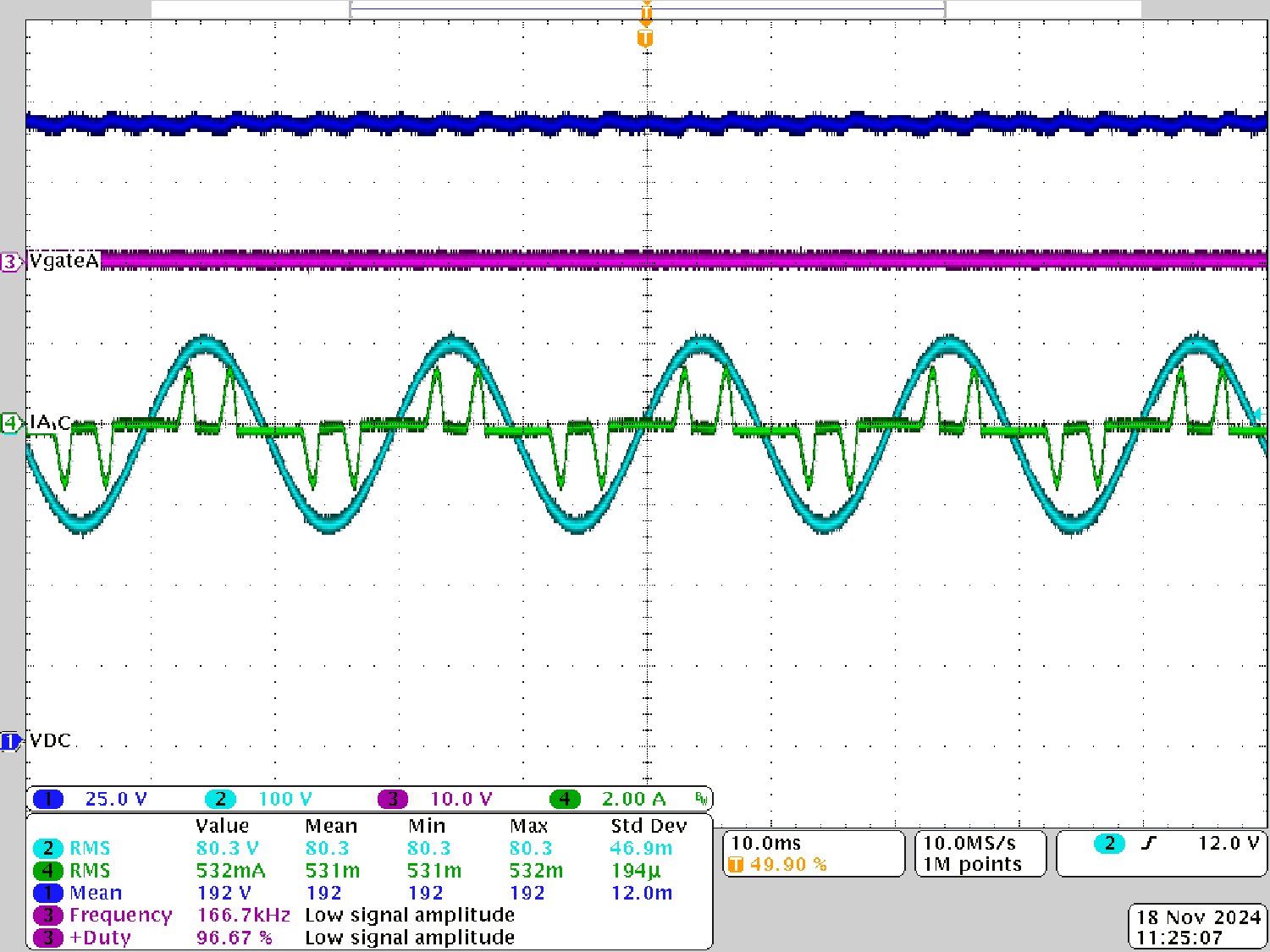

Figure 3-12 Build Level 1: Graph Showing Measured Currents - Figure 3-13 shows the scope capture of the input voltage and current.

Figure 3-13 Build Level 1: Scope Capture Ia and Va (80VRMS L-N) With PWM Tripped

Figure 3-13 Build Level 1: Scope Capture Ia and Va (80VRMS L-N) With PWM Tripped- CH1 (Blue): DCBUS output voltage

- CH2 (Light blue): AC input phase A voltage

- CH3 (Pink): IGBT gate voltage

- CH4 (Green): AC Input phase A current

- Verify the PWM action, first reduce the input voltage to zero and wait for all the voltages to go down to zero.

- Set the

dutyPU_DCvariable to 0.5 in the expressions view. - Clear the PWM trip by writing a 1 to

clearTrip. - Slowly increase the input voltage and keep watching the input current. The duty cycle imparts a boost action. For example, when VAC is 80VRMS without switching enabled, the

guiVbusis about 190V; with switching, theguiVbusrises up to 380V. Thus,guiVbusPMandguiVbusMNare both higher than the input voltage maximum. - Below are the test conditions described in this build, the

guiVbusvariable rises to about 380V andguiVbusPMandguiVbusMNare close to 190V each, and the current is close to 1.1ARMS when the input voltage reaches 80VRMS L-N. The Expressions view appears as shown in step Figure 3-14. Make sure all the variables are accurate, that is,guiVrms1,guiVrms2,guiVrms3,guiIrms1,guiIrms2,guiIrms3,guiPF1,guiPF2, andguiPF3. If any variable is not accurate (as shown in Figure 3-14), this means there is a hardware issue with the sensing circuit. Figure 3-14 Build Level 1: Expressions View With Power Measurement

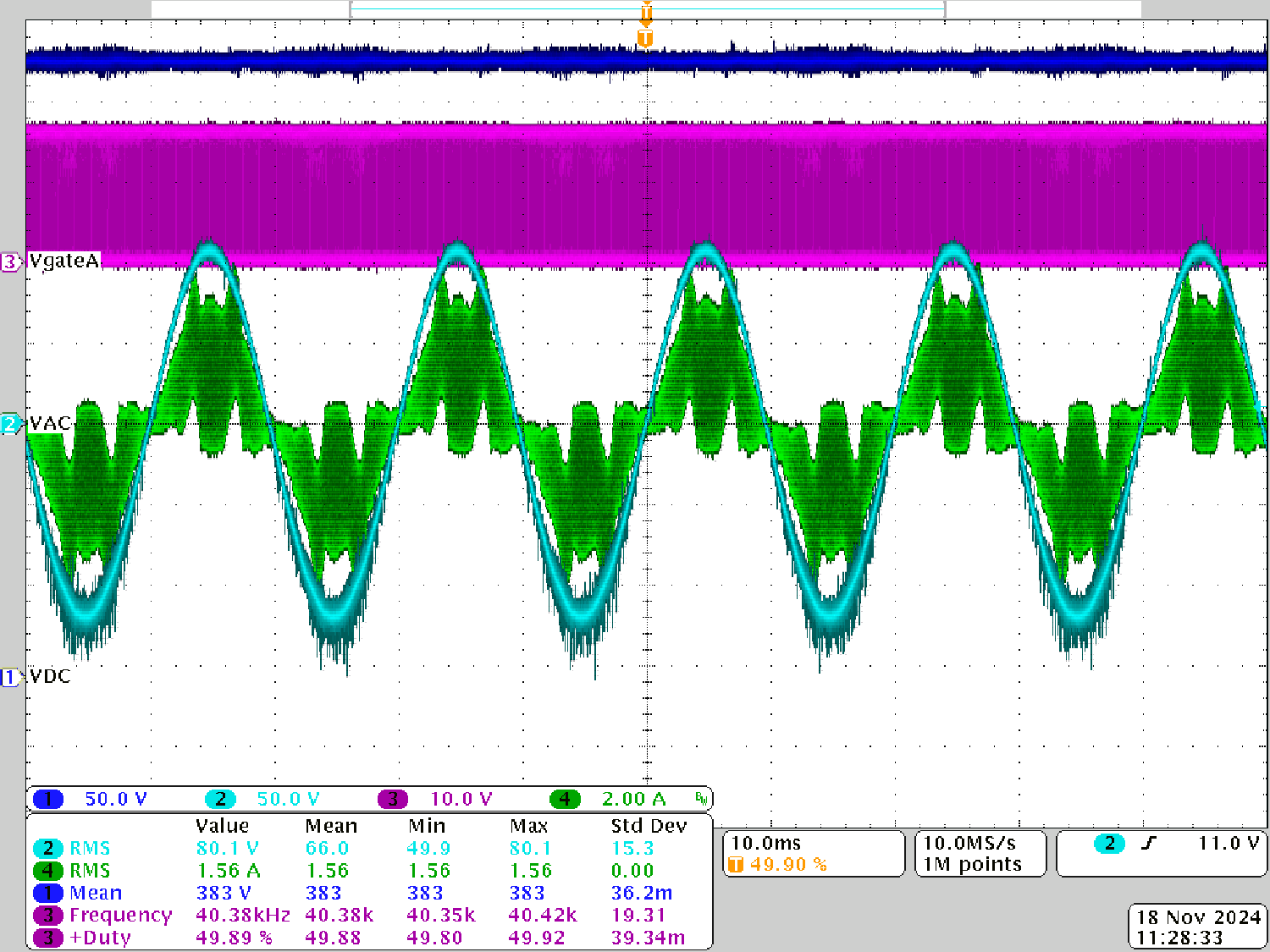

Figure 3-14 Build Level 1: Expressions View With Power Measurement - Figure 3-15 shows the scope capture.

Figure 3-15 Build Level 1: Scope Capture Ia and Va (80VRMS L-N) With Duty Cycle 0.5

Figure 3-15 Build Level 1: Scope Capture Ia and Va (80VRMS L-N) With Duty Cycle 0.5- CH1 (Blue): DCBUS output voltage

- CH2 (Light blue): AC input phase A voltage

- CH3 (Pink): IGBT gate voltage

- CH4 (Green): AC Input phase A current

- This check verifies at a basic level the PWM driver and connection of the hardware.

- Reduce the input voltage to zero, and watch for the bus voltages to reduce down to zero.

- This completes the check for this build, the following items are verified on successful completion of this build:

- Sensing of voltages and currents and scaling to be correct

- Interrupt generation and execution of the build 1 code in the

controlISRandtenkHzISR()variables - PWM driver and switching

- The controller can now be halted, and the debug connection terminated.

- Fully halting the MCU when in real-time mode is a two-step process. First halt the processor by using the Halt button on the toolbar (

) or by using Target → Halt. Then take the MCU out of real-time mode by clicking on the

) or by using Target → Halt. Then take the MCU out of real-time mode by clicking on the  icon. Finally, reset the MCU by clicking on the

icon. Finally, reset the MCU by clicking on the  button.

button. - Close the CCS debug session by clicking on Terminate Debug Session (Target > Terminate all).