TIDUFB8 December 2024

- 1

- Description

- Resources

- Features

- Applications

- 6

- 1System Description

- 2System Overview

- 3Hardware, Software, Testing Requirements, and Test Results

- 4Design and Documentation Support

- 5About the Author

3.3.2 Viewing Metrology Readings and Calibration

To view the metrology parameter values from the GUI, perform the following steps:

- Select UART connection for communication to the PC GUI. Connect J12 to PC USB and a COM port is created on the PC. The testing was done using UART with 9600, 8N1 setting.

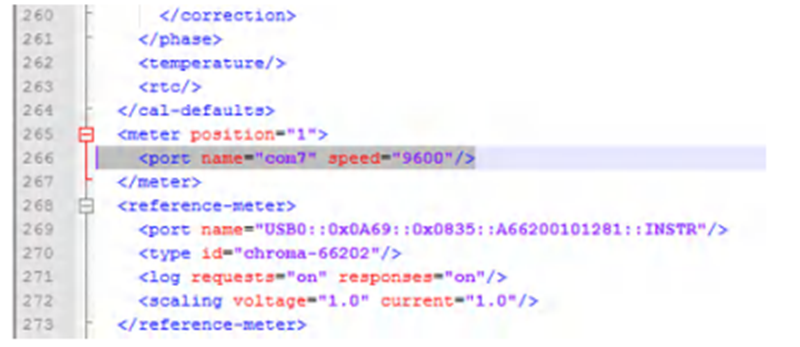

- Open the GUI folder and open

calibration-config.xmlin a text editor. - Change the port name field within

the meter tag to the COM port connected to the system. As Figure 3-8 shows, this field is changed to COM7.

Figure 3-8 GUI Configuration File

Changed to Communicate With Energy Measurement System

Figure 3-8 GUI Configuration File

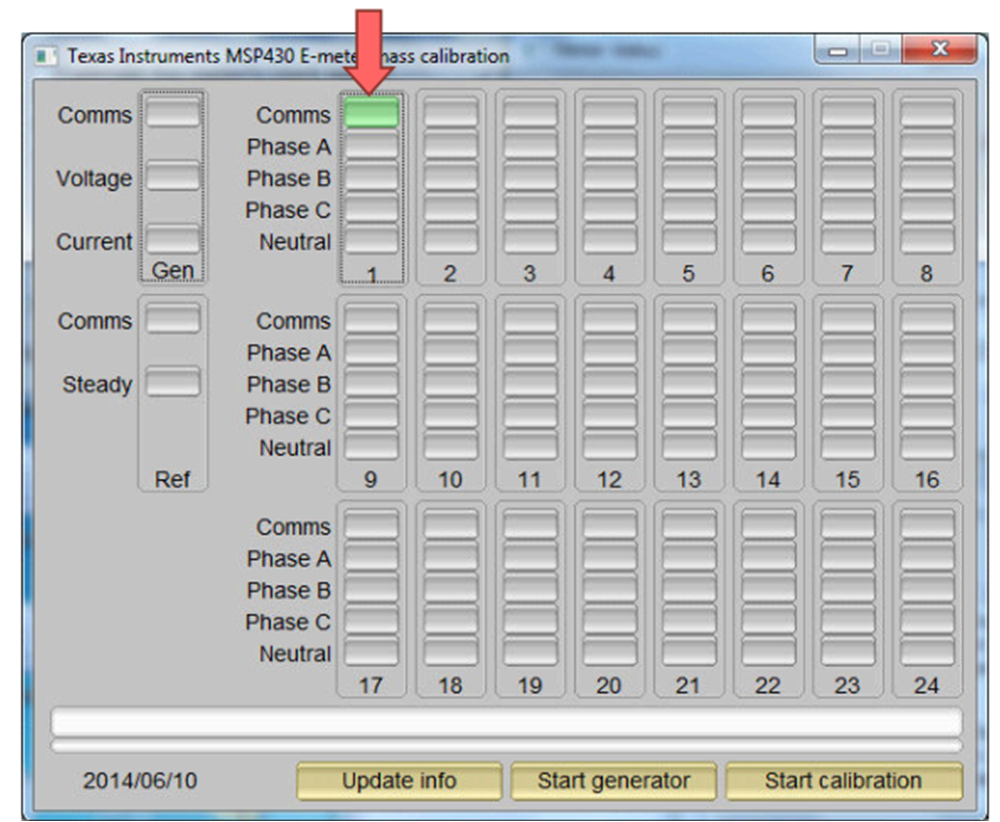

Changed to Communicate With Energy Measurement System - Run the

calibrator.exefile, which is located in the GUI folder. If the COM port in thecalibration-config.xmlwas changed in the previous step to the COM port connected to the reference design, the GUI opens (see Figure 3-9). If the GUI connects to the design properly, the top-left button is green. If there are problems with connections or if the code is not configured correctly, the button is red. Click the green button to view the results. Figure 3-9 GUI Start-Up

Window

Figure 3-9 GUI Start-Up

Window

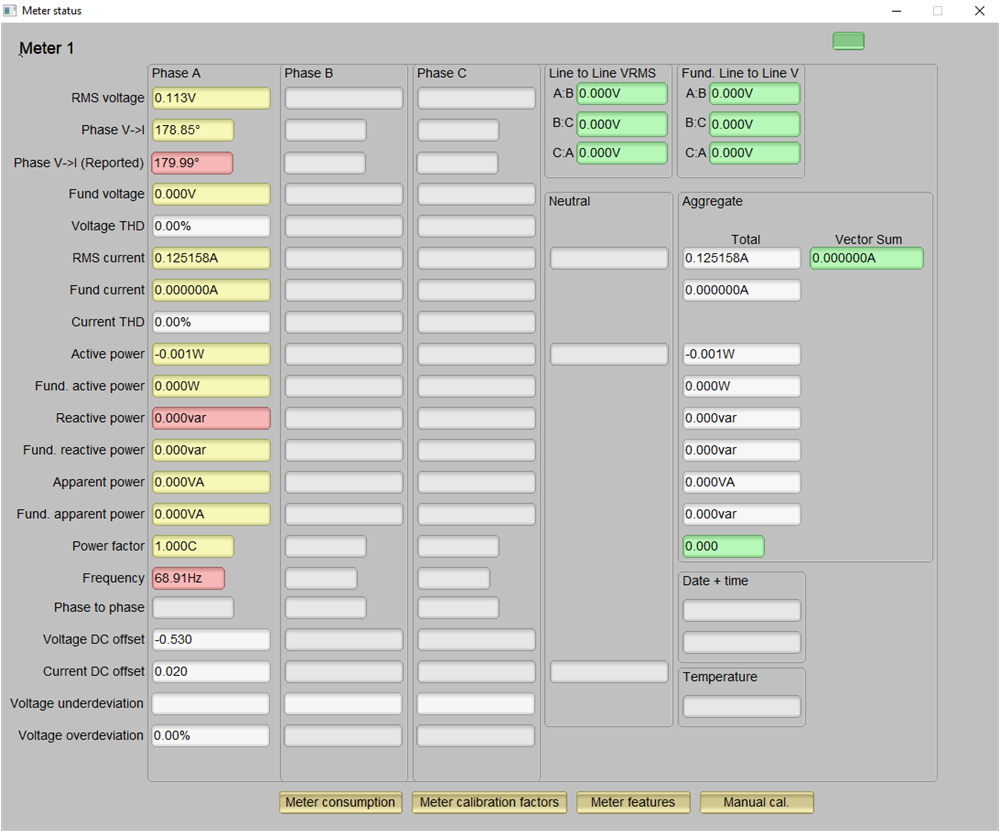

The results window opens after clicking on the green button (see Figure 3-10).

Figure 3-10 GUI Results Window

Figure 3-10 GUI Results Window