Modern, Sleek and Durable Touch on Metal HMIs

Dan Torres

Many industrial and consumer electronic product designers use metal in their designs due to its modern look and durability. However, implementing human machine interfaces (HMIs) on metal surfaces is challenging, as it requires machining and cutting a hole to accommodate a mechanical button. In addition to compromising the aesthetics of the design, mechanical buttons are also prone to failure in moist, dusty or dirty conditions.

Touch through metal allows for sleek touch sensing designs that are waterproof, dustproof, wear-resistant and highly immune to noise. Touch through metal works even when users are wearing gloves and can detect the pressure difference between soft and hard touches, making it a good fit for building security systems, appliances, industrial applications and personal electronics.

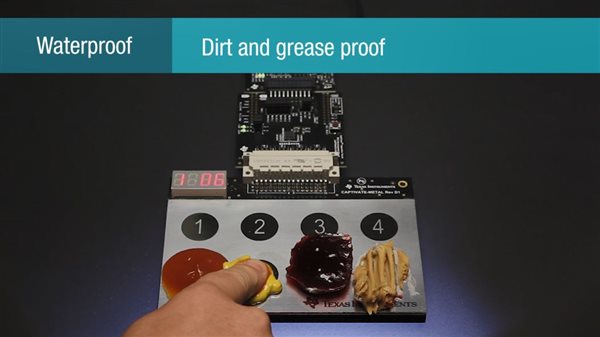

Figure 1 Example of Dirt and Grease

Proof Touch through Metal Using CapTIvate Technology

Figure 1 Example of Dirt and Grease

Proof Touch through Metal Using CapTIvate TechnologyMSP430™ microcontrollers (MCUs) with CapTIvate™ touch technology bring the flexibility, innovation and reliability characteristic of capacitive touch inputs to applications ranging from appliances to portable electronics. MCUs with CapTIvate technology can implement capacitive touch through metal overlays, allowing highly reliable and sophisticated buttons, sliders and wheels.

In a traditional capacitive touch approach, a touch sensor connected to an MSP430 MCU emits an e-field and detects a change in capacitance when a human finger comes into that e-field. This mechanism works well with plastic, glass and other nonconductive overlay material, but doesn’t work at all with a metal overlay.

MSP430 MCUs with CapTIvate technology use an alternate approach. The stack-up comprises a printed circuit board with traditional capacitive touch sensors and a spacer topped with a grounded metal overlay. This mechanical structure forms a variable capacitor that generates changes in value when a user applies force to the buttons, sliders or wheels. The sensitivity of the integrated CapTIvate peripheral on the MSP430FR2633 family of MCUs allows the detection of a few micron-level deflections of the metal plate.

Because an actuation force is necessary in order to interact with the buttons, metal overlays are waterproof, dirt proof and work even if users are wearing thick gloves. Furthermore, based on the force and amount of deflection, you can implement features incorporating pressure sensing or force on the buttons, sliders and wheels.

The CapTIvate metal touch panel is an add-on board for the CapTIvate development kit. This alternative technology to traditional capacitive touch sensors enables stylish touch module designs using stainless steel, aluminum alloys, brass and bronze. This add-on board features:

- Capacitive touch with metal overlays

- Variable force touch detection

- Multi-key touch

- 7-segment display feedback

- Water, grease and dirt proof

Everything you need for developing your capacitive touch solution, including silicon, software, reference designs, code examples, in-depth documentation, training, and online E2E support, is at your finger-tips at www.ti.com/captivate.

Additional resources:

- Watch this video to learn how capacitive metal touch works

- See a demonstration of the CAPTIVATE-METAL EVM

- Read this application note on touch through metal technology

IMPORTANT NOTICE AND DISCLAIMER

TI PROVIDES TECHNICAL AND RELIABILITY DATA (INCLUDING DATASHEETS), DESIGN RESOURCES (INCLUDING REFERENCE DESIGNS), APPLICATION OR OTHER DESIGN ADVICE, WEB TOOLS, SAFETY INFORMATION, AND OTHER RESOURCES “AS IS” AND WITH ALL FAULTS, AND DISCLAIMS ALL WARRANTIES, EXPRESS AND IMPLIED, INCLUDING WITHOUT LIMITATION ANY IMPLIED WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE OR NON-INFRINGEMENT OF THIRD PARTY INTELLECTUAL PROPERTY RIGHTS.

These resources are intended for skilled developers designing with TI products. You are solely responsible for (1) selecting the appropriate TI products for your application, (2) designing, validating and testing your application, and (3) ensuring your application meets applicable standards, and any other safety, security, or other requirements. These resources are subject to change without notice. TI grants you permission to use these resources only for development of an application that uses the TI products described in the resource. Other reproduction and display of these resources is prohibited. No license is granted to any other TI intellectual property right or to any third party intellectual property right. TI disclaims responsibility for, and you will fully indemnify TI and its representatives against, any claims, damages, costs, losses, and liabilities arising out of your use of these resources.

TI’s products are provided subject to TI’s Terms of Sale (www.ti.com/legal/termsofsale.html) or other applicable terms available either on ti.com or provided in conjunction with such TI products. TI’s provision of these resources does not expand or otherwise alter TI’s applicable warranties or warranty disclaimers for TI products.

Mailing Address: Texas Instruments, Post Office Box 655303, Dallas, Texas 75265

Copyright © 2023, Texas Instruments Incorporated