Unique Techniques to Increase Controller Power

The better you understand a tool, the more powerful it becomes.

One example of this is the Tektronix 576 curve tracer. At first glance, it looks like a machine that only measures a three-terminal bipolar junction transistor (BJT) or field-effect transistor (FET). That’s how it was advertised, so that’s what I thought until an especially talented product and failure analysis engineer showed me otherwise. He demonstrated that this machine is really just a precise voltage and current supply with accurate measurements of both, down to the megavolts/nanoampere range. By dynamically measuring a current-voltage (I-V) curve graphically, this tool is actually one of the most powerful circuit debugging machines in the lab.

At first I was skeptical that an old analog machine with a phosphorous cathode ray tube (CRT) monitor and mechanical switches was capable of supplying over 1kV. My doubts didn’t last long, though, since there was soon a puzzling failure on a reliability test that we were running for a device in development, with a public announcement approaching. Using the curve tracer, we were able to track down the root cause to intermittent pin-to-pin shorts of the quad flat no-lead (QFN) package due to board-level issues. We shared the results with cellphone pictures of the CRT monitor; this old machine, designed for a different purpose, clearly showed the voltage collapsing momentarily as shorts between two pins formed and then fused open.

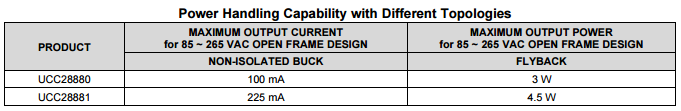

The same applies to any device used in a circuit, just because it’s advertised to work in one specific case doesn’t mean it will work well elsewhere. While it may be easy to read the first page of a data sheet and assume that the device can only work in the specific configurations listed, that is not always the case. One example is the maximum power of the offline converter for TI’s UCC28880 and UCC28881 switchers. At the beginning of the datasheet a table is provided to help readers understand when which device should be used, as shown with Figure 1.

Figure 1 Power-rating Table in the

UCC28881 Data Sheet

Figure 1 Power-rating Table in the

UCC28881 Data SheetWhile this table implies that 4.5W is the maximum power that this family of devices is capable of supplying when configured as a flyback, this is not necessarily the case. The maximum power limit comes from the peak current limit (ILIMIT) of the device. This current reaches its limit at the lowest power level at the minimum input voltage, which is 85V for a design that can support a universal input. If the input is limited to just low line (i.e. North America, Japan) or high line (i.e. Europe, Asia), the maximum capable power level is actually higher. While it’s obvious for high line since it has lower input currents for the same power level, low line only input requires a slight modification to the typical schematic.

This is demonstrated with 100V-450VDC, 5W, 80% Efficiency at 1W, Auxiliary Supply Reference Design for AC-DC Power Supplies. By having a 100V DC input instead of an 85V AC input, the minimum input voltage is higher. This enables this design with UCC28881 to have a maximum power of 5W, which is above the 4.5W maximum of the table in the data sheet. This increase cannot continue forever though, since other limitations like thermal capability start to have an impact and can limit the operating range from reaching its theoretical capability.

Techniques like this are not limited to maximum power capability. I’ve compiled a list of reference designs that show other unique ways to bias offline power-supply controllers so that they work in conditions beyond what’s typically advertised.

- Integrated FET devices can operate with input voltages beyond their internal high-voltage FET ratings in the 166VAC to 528VAC Input, 5V and 24V Dual-Output Reference Design with Cascode-MOSFET Configuration

- The UCC28880 can operate over a wicked-wide range of lower DC voltage to high-line AC of 24VDC to 265VAC, in the Low Power Flyback Bias Supply Reference Design With Ultra Wide Input Voltage Range

- You can configure a single-ended output flyback controller to control a two-switch flyback with the High Efficiency and Low Total Harmonic Distortion 200W AC-DC LED Driver Reference Design and PSR Flyback Reference Design for 120V±15% AC Input and 24V/6A Output

IMPORTANT NOTICE AND DISCLAIMER

TI PROVIDES TECHNICAL AND RELIABILITY DATA (INCLUDING DATASHEETS), DESIGN RESOURCES (INCLUDING REFERENCE DESIGNS), APPLICATION OR OTHER DESIGN ADVICE, WEB TOOLS, SAFETY INFORMATION, AND OTHER RESOURCES “AS IS” AND WITH ALL FAULTS, AND DISCLAIMS ALL WARRANTIES, EXPRESS AND IMPLIED, INCLUDING WITHOUT LIMITATION ANY IMPLIED WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE OR NON-INFRINGEMENT OF THIRD PARTY INTELLECTUAL PROPERTY RIGHTS.

These resources are intended for skilled developers designing with TI products. You are solely responsible for (1) selecting the appropriate TI products for your application, (2) designing, validating and testing your application, and (3) ensuring your application meets applicable standards, and any other safety, security, or other requirements. These resources are subject to change without notice. TI grants you permission to use these resources only for development of an application that uses the TI products described in the resource. Other reproduction and display of these resources is prohibited. No license is granted to any other TI intellectual property right or to any third party intellectual property right. TI disclaims responsibility for, and you will fully indemnify TI and its representatives against, any claims, damages, costs, losses, and liabilities arising out of your use of these resources.

TI’s products are provided subject to TI’s Terms of Sale (www.ti.com/legal/termsofsale.html) or other applicable terms available either on ti.com or provided in conjunction with such TI products. TI’s provision of these resources does not expand or otherwise alter TI’s applicable warranties or warranty disclaimers for TI products.

Mailing Address: Texas Instruments, Post Office Box 655303, Dallas, Texas 75265

Copyright © 2023, Texas Instruments Incorporated