-

Using mmWave Technology to Enable Sense and Avoidance in Drones

Using mmWave Technology to Enable Sense and Avoidance in Drones

Yan LI

Despite the great advantages to be gained from the use of drones in civil applications, such as weather forecasting, package delivery and 3-D mapping, the drone industry faces a dual challenge: the demand for both safer flights and lower prices. Most drones on the market today are not equipped with sense-and-avoid (SAA) technology and pose potential hazards to people or vehicles nearby. Therefore, the Federal Aviation Administration (FAA) requires that all pilots who fly drones for work or business must obey the small Unmanned Aircraft Systems (UAS) rules (14 Code of Federal Regulations [CFR] part 107), which specify keeping the aircraft within their visual line of sight and not flying over people or moving vehicles.

Most collision-avoidance systems currently on the market can be separated into three categories: vision, ultrasound and infrared or laser. Vision-based collision-avoidance systems are precise in identifying objects in the close distance, but their performance is sensitive to weather and light condition. Ultrasound collision-avoidance systems are the most economical, but their sensing range is limited. Infrared or laser collision-avoidance systems have the longest sensing range but are easily affected by weather and light and are very expensive. Therefore, most drones on the market today, such as the DJI Phantom 4 and Yuneec Typhoon-H, use vision-based collision-avoidance systems with dual cameras to sense obstacles.

Recently, the application of radar in the drone industry has begun to attract lots of attention. Radar uses radio waves to determine the range, angle or velocity of objects. Due to its extremely high cost, large size and high power consumption, only automotive safety and weather-forecasting applications had adopted radar technology, although it has been used extensively in military applications for almost 80 years. But with the recent, rapid development of integrated circuit (IC) technology, traditional radar systems can now fit into small chips, paving the way for radar-based SAA solutions for drones.

Compared to existing 24GHz radar, TI’s 76-81 GHz millimeter-wave (mmWave) radar operates at a higher frequency with a wider bandwidth, which enables better range and velocity resolution. With an integrated MCU and DSP, it also reduces the size of the radar system significantly. Previously, most millimeter-wave chips on the market only integrated the radar transmitters and receivers, while developers had to add additional components such as the analog-to-digital converter (ADC) and digital signal processor (DSP). This dramatically increases the cost and size of the radar system.

TI’s IWR1642, a single-chip mmWave sensor, has two transmitters, four receiver antennas and four-channel high-speed ADCs. It also comes with Controller Area Network (CAN), CAN-Flexible Data Rate (FD) and Universal Asynchronous Receiver Transmitter (UART) data output interfaces. The ARM® Cortex®-R4F and TI C674x DSP handle the data processing.

This highly integrated radio frequency (RF) and processor package offers a compact yet powerful core for drone collision sensing solutions. The integrated C674x DSP processor provides sufficient computational power to conduct signal-processing algorithms that calculate range, azimuth and velocity information for several objects, while the ARM core is responsible for configuring the chip and formatting the output data.

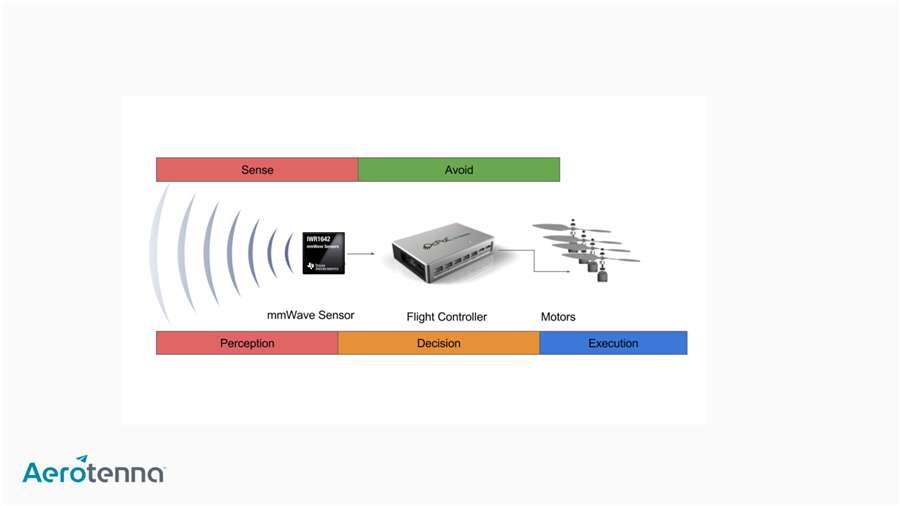

Figure 1 Architecture of Collision

Avoidance Solution with TI mmWave

Figure 1 Architecture of Collision

Avoidance Solution with TI mmWaveAt the drone system level, the IWR1642 enables special mmWave sensing capabilities for drones to sense their surroundings. The processed information can then be sent to a flight controller (like the Aerotenna octagonal pilot-on-chip [OcPoC] flight controller with flexible interfaces, programmable inputs/outputs (I/Os) and a system-on-chip (SoC) field-programmable gate array [FPGA]-plus ARM hybrid processing architecture) to calculate and execute avoid commands. The integrated computational power in the IWR1642 helps reduce the data rate and simplifies the interfacing communication between the sensors and the flight controller. Thus, the design engineers can de-couple the sense-and-avoid tasks and distribute them into two functional units of the drone system.

Working in harmony with the IWR1642 handling the sensing, a smart flight controller such as the Aerotenna OcPoC can handle the avoidance. Together, this sense-and-avoid solution can vastly reduce the integration and development required to take full advantage of the IWR1642 mmWave sensor. Furthermore, Aerotenna’s collision avoidance solution, enabled by TI mmWave technology, has the potential to address the concern behind the strict FAA rules regarding line of sight UAV flight, allowing certain vehicles with this collision avoidance capability to fly safely in some beyond-line-of-sight situations. With close collaboration between regulators and the industry, technology like this may render this rule unnecessary in the future.

Additional Resources:

- See the closed-loop sense and avoid package in action in this video.

- Learn how mmWave sensor technology works.

- Learn more about TI's approach to drone vision.

- See how mmWave sensors work in drone applications in the white paper, “Drone safety and productivity enabled by mmWave sensors.”

- See how TI is “Bringing new intelligence to industrial applications with mmWave sensors” in the Industrial Strength blog.

IMPORTANT NOTICE AND DISCLAIMER

TI PROVIDES TECHNICAL AND RELIABILITY DATA (INCLUDING DATASHEETS), DESIGN RESOURCES (INCLUDING REFERENCE DESIGNS), APPLICATION OR OTHER DESIGN ADVICE, WEB TOOLS, SAFETY INFORMATION, AND OTHER RESOURCES “AS IS” AND WITH ALL FAULTS, AND DISCLAIMS ALL WARRANTIES, EXPRESS AND IMPLIED, INCLUDING WITHOUT LIMITATION ANY IMPLIED WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE OR NON-INFRINGEMENT OF THIRD PARTY INTELLECTUAL PROPERTY RIGHTS.

These resources are intended for skilled developers designing with TI products. You are solely responsible for (1) selecting the appropriate TI products for your application, (2) designing, validating and testing your application, and (3) ensuring your application meets applicable standards, and any other safety, security, or other requirements. These resources are subject to change without notice. TI grants you permission to use these resources only for development of an application that uses the TI products described in the resource. Other reproduction and display of these resources is prohibited. No license is granted to any other TI intellectual property right or to any third party intellectual property right. TI disclaims responsibility for, and you will fully indemnify TI and its representatives against, any claims, damages, costs, losses, and liabilities arising out of your use of these resources.

TI’s products are provided subject to TI’s Terms of Sale (www.ti.com/legal/termsofsale.html) or other applicable terms available either on ti.com or provided in conjunction with such TI products. TI’s provision of these resources does not expand or otherwise alter TI’s applicable warranties or warranty disclaimers for TI products.

Mailing Address: Texas Instruments, Post Office Box 655303, Dallas, Texas 75265

Copyright © 2023, Texas Instruments Incorporated