-

Advancements in X-ray Imaging

Advancements in X-ray Imaging

Diagnostic imaging technologies like X-ray systems are continuously evolving to improve not just the quality of patient diagnostics but also clinical efficiency. The ability to accurately and cost-effectively capture detailed images of the human body to achieve these goals is becoming increasingly critical across small to large modern medical practices, due to the market becoming more competitive. Additionally as the market becomes more competitive, there erupts numerous advancements in the technology.

Introduced in the mid-1990s, X-ray systems capture higher-quality images at higher resolutions than ever before, all while requiring less time to capture. Digital X-ray systems have revolutionized diagnostic radiology. Many of the improvements in X-ray systems are a direct result of the advantages of digital capture over traditional film capture.

Digital X-ray systems have a higher dynamic range than film, which allows for clearer, more detailed images. Since digital X-ray systems do not require extensive processing, there is a significant reduction in the time it takes to deliver images to radiologists and ultimately patients. Digital capture also improves image-processing capabilities such as spatial zooming and contrast enhancement. Finally, there are more convenient storage options for digital images than film, and digital storage reduces the amount of polluting waste products.

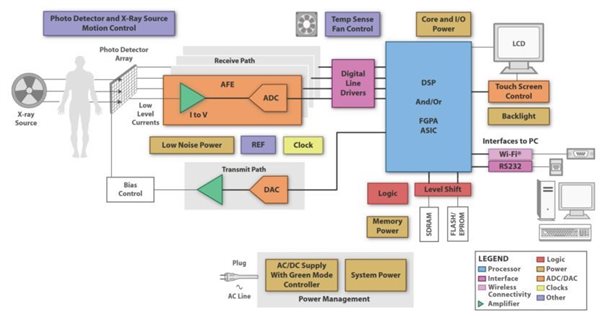

Given all of the improvements over the years, X-ray systems have become very complex and require an analog front end (AFE), a digital signal processor (DSP), an LCD, power supply design, sensor controls and a few other external components. The block diagram in Figure 1 shows the readout electronics required for direct imaging to convert a charge in a flat panel detector (FPD) to digital data. There are two chains: the acquisition chain and the biasing chain. At the start of the acquisition chain, an AFE circuit (sometimes called the readout integrated circuit) digitizes the charges from the array of pixels on the FPD. The biasing chain generates bias voltages for the thin film transistor (TFT) array through intermediate bias and gate control circuitry. A DSP, field-programmable gate array (FPGA), application-specific integrated circuit (ASIC) or a combination of these applies signal conditioning. These processors also manage high-speed serial communications with the external image-processing unit through a high-speed interface.

Figure 1 X-ray System

Figure 1 X-ray SystemDevices like the AFE2256 AFE are specifically designed for FPD-based digital X-ray systems. This device can be used for static or dynamic imaging and also features multiple sleep and power-down modes that are especially useful for battery-powered systems. The AFE2256 has 256 channels and an onboard 16-bit ADC.

With the evolution of X-ray systems, there is an increasing demand for clearer, more detailed images, faster scan times, better storage options and simpler power-supply schemes. The ability to accurately and cost-effectively achieve these goals becomes easier with a device like the AFE2256. There are a few key differentiators of this device to others on the market. The AFE2256 is very easy to use; there is a simple power supply management scheme enabling smaller board space and less external circuitry. This device also has low power consumption, especially at low integration times, which enables longer battery life. There is also low noise: 750 electrons RMS with 1.2pC input charge range, which enables lower dosage and dynamic imaging resulting in clearer images. Faster scan times (less than 20s) also allow for more efficient image captures.

TI has a long history and continually invests in digital X-ray technology. To learn more, check out our entire X-ray portfolio, including the AFE2256.

Additional Resources

- Download the AFE2256 data sheet.

IMPORTANT NOTICE AND DISCLAIMER

TI PROVIDES TECHNICAL AND RELIABILITY DATA (INCLUDING DATASHEETS), DESIGN RESOURCES (INCLUDING REFERENCE DESIGNS), APPLICATION OR OTHER DESIGN ADVICE, WEB TOOLS, SAFETY INFORMATION, AND OTHER RESOURCES “AS IS” AND WITH ALL FAULTS, AND DISCLAIMS ALL WARRANTIES, EXPRESS AND IMPLIED, INCLUDING WITHOUT LIMITATION ANY IMPLIED WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE OR NON-INFRINGEMENT OF THIRD PARTY INTELLECTUAL PROPERTY RIGHTS.

These resources are intended for skilled developers designing with TI products. You are solely responsible for (1) selecting the appropriate TI products for your application, (2) designing, validating and testing your application, and (3) ensuring your application meets applicable standards, and any other safety, security, or other requirements. These resources are subject to change without notice. TI grants you permission to use these resources only for development of an application that uses the TI products described in the resource. Other reproduction and display of these resources is prohibited. No license is granted to any other TI intellectual property right or to any third party intellectual property right. TI disclaims responsibility for, and you will fully indemnify TI and its representatives against, any claims, damages, costs, losses, and liabilities arising out of your use of these resources.

TI’s products are provided subject to TI’s Terms of Sale (www.ti.com/legal/termsofsale.html) or other applicable terms available either on ti.com or provided in conjunction with such TI products. TI’s provision of these resources does not expand or otherwise alter TI’s applicable warranties or warranty disclaimers for TI products.

Mailing Address: Texas Instruments, Post Office Box 655303, Dallas, Texas 75265

Copyright © 2023, Texas Instruments Incorporated