MTBF/FIT estimator

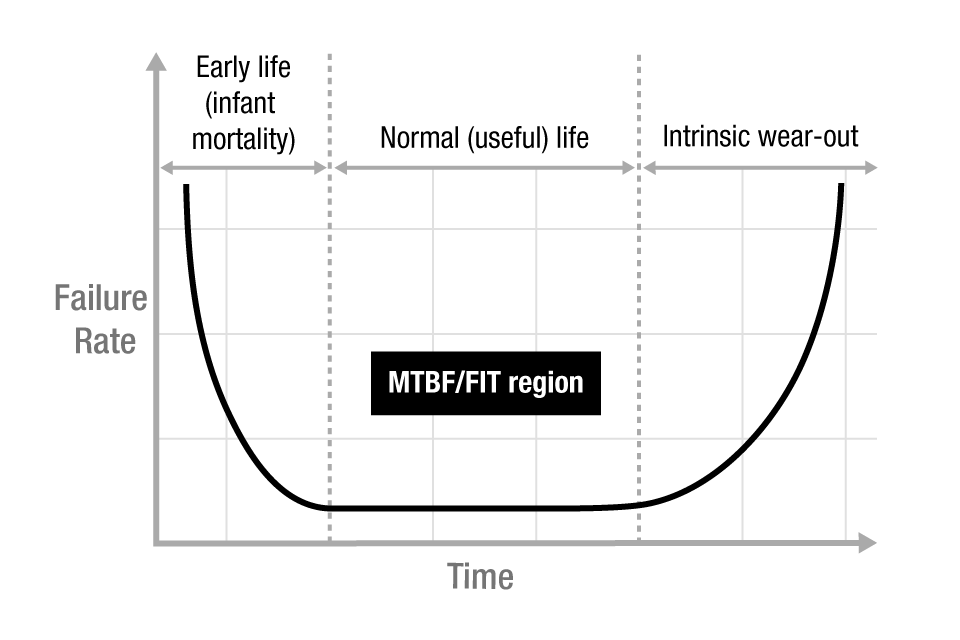

The purpose of qualification testing is to determine the life of a product, and most device lifetimes can be represented by this simple curve from the potential early fail rates to the eventual life wear out.

Mean Time Between Fails (MTBF) and Failures in Time (FIT) rates are typical statistics customers ask for when inquiring about a device’s reliability. These measures of a product’s life are calculated via the data taken to understand these questions. These values are calculated by TI’s internal reliability testing.

TI’s MTBF/FIT estimator search tool allows you to find generic data based on technology groupings to estimate these typical questions and shows conditions under which the rates were derived.

Simply enter a part number, and the tool will present the data. All terms used in the tool and definitions can be found on our reliability terminology page.

The following failure rates are summarized by technology and mapped to the associated material part numbers. The failure rates are highly dependent on the number of units tested, therefore, it is not recommended to compare failure rates.

| MTBF / FIT | MTBF / FIT supporting data | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Part number | MTBF | FIT | Usage temp (°C) | Conf level (%) | Activation energy (eV) | Test temp (°C) | Test duration (hours) | Sample size | Fails | Additional comments |

| TPS3803-01DCKR | 1.61x 10 9 | 0.6 | 55 | 60.0 | 0.7 | 125 | 1000 | 18799 | 0 | - |

Definition of Table Terminology

Part #:The TI orderable part number

MTBF: Mean Time Between Failures

FIT: Failures-in-Time. The number of failures per 1E9 device-hours

Conf level %: Statistical confidence level

Test temp (°C): Temperature at which the stress test is performed

Sample size: Sample size is how many units were tested and would be based on the normalized value for duration

Fails: The number of failures per test

Usage temp (°C): Estimated usage temperature

Activation energy (eV): Energy in electron volts (eV) for a particular process to occur

Test duration (hrs): Test duration is a field that comes from the qualification testing of a product. Since more than one test is conducted and the duration varies, this field will be normalized based on calculations using temp, quantity and fails. This value would be equivalent unit hours.

NA: Not Applicable

TBD: To Be Determined

Disclaimer

Important limitations on use of data exceeding specified limits

TI is providing this data for your convenience. However, we want to make clear the significant limitations of its usefulness as an indicator of how devices may perform in various applications.

THIS DATA IS PROVIDED "AS IS" WITHOUT ANY EXPRESS OR IMPLIED WARRANTY OF ANY KIND INCLUDING WARRANTIES OF MERCHANTABILITY, NONINFRINGEMENT OF INTELLECTUAL PROPERTY, OR FITNESS FOR ANY PARTICULAR PURPOSE. IN NO EVENT SHALL TI OR ITS SUPPLIERS BE LIABLE FOR ANY DAMAGES WHATSOEVER (INCLUDING, WITHOUT LIMITATION, DAMAGES FOR LOSS OF PROFITS, BUSINESS INTERRUPTION, LOSS OF INFORMATION) ARISING OUT OF THE USE OF OR INABILITY TO USE THE INFORMATION, EVEN IF TI HAS BEEN ADVISED OF THE POSSIBILITY OF SUCH DAMAGES.

Your use of this data, and all consequences of such use, is solely your responsibility. You must perform sufficient engineering and additional qualification testing in order to properly evaluate your application and determine whether a candidate device is suitable for use in that application.

TI semiconductor components are specifically designed and manufactured to be used within the electrical, thermal, mechanical and other parameters set forth in TI's product data sheets. Quality and reliability data provided by Texas Instruments, such as MTBF and fit rate data, is intended to be an estimate of product performance based upon history only. It does not imply that any performance levels reflected in such data can be met if the product is operated outside the conditions expressly stated in the latest published data sheet for a device.

Plastic encapsulated TI semiconductor devices are neither designed nor warranted as suitable for use in military applications and/or military environments.

THIS INFORMATION SHOULD NOT BE USED TO ASSIST IN THE PRACTICE OF "UPRATING" OR "UPSCREENING" DEVICES FOR USE IN MILITARY OR OTHER CRITICAL APPLICATIONS. There are significant limitations of this information as an indicator of how commercial, off-the-shelf (COTS) devices may perform in such applications or environments, and about the hazards of using COTS devices in such applications. TI strongly believes that semiconductor components should never be used outside their specified tolerance levels as upscreening can lead directly to system or component failure. Such failures may present distinct risks to end-users and to third parties. TI cannot accept any responsibility for component or system failures that occur due to the misuse of its products, including misuse that may result from the practice of upscreening.

Any use of TI components beyond their rated limits voids all warranty responsibility of TI with respect to such devices, and also voids all responsibility of TI with respect to any applications assistance, product design, software performance or services of any kind that were or may have been performed in connection with the sale of any such devices. Further, resale of TI''s products or services with statements different from or beyond the parameters stated by TI for that product or service in official TI data books or data sheets, or without the warnings or instructions provided by TI, voids all express and any implied warranties for the associated TI product or service, and is an unfair and deceptive business practice.

For additional information, please contact TI customer support.