SLUSAW9F February 2012 – November 2014 UCC27511 , UCC27512

PRODUCTION DATA.

- 1 Features

- 2 Applications

- 3 Description

- 4 Revision History

- 5 Description (Continued)

- 6 UCC2751x Product Family

- 7 Pin Configuration and Functions

- 8 Specifications

- 9 Detailed Description

- 10Application and Implementation

- 11Power Supply Recommendations

- 12Layout

- 13Device and Documentation Support

- 14Mechanical, Packaging, and Orderable Information

Package Options

Mechanical Data (Package|Pins)

- DRS|6

Thermal pad, mechanical data (Package|Pins)

- DRS|6

Orderable Information

8 Specifications

8.1 Absolute Maximum Ratings(1)(2)(3)

over operating free-air temperature range (unless otherwise noted)| MIN | MAX | UNIT | ||

|---|---|---|---|---|

| Supply voltage range | VDD | –0.3 | 20 | V |

| OUTH voltage, (UCC27511) | –0.3 | VDD + 0.3 | ||

| OUTL voltage, (UCC27511) | DC | –0.3 | 20 | |

| Repetitive pulse less than 200 ns(5) | –2 | 20 | ||

| OUT voltage, (UCC27512) | DC | –0.3 | VDD + 0.3 | |

| Repetitive pulse less than 200 ns(5) | –2 | VDD + 0.3 | ||

| Output continuous current (OUTH source current and OUTL sink current) |

IOUT_DC (source) | 0.3 | A | |

| IOUT_DC (sink) | 0.6 | |||

| Output pulsed current (0.5 µs) (OUTH source current and OUTL sink current) |

IOUT_pulsed(source) | 4 | ||

| IOUT_pulsed(sink) | 8 | |||

| IN+, IN–(4) | –0.3 | 20 | V | |

| Lead temperature | Soldering, 10 sec. | 300 | °C | |

| Reflow | 260 | |||

(1) Stresses beyond those listed under Absolute Maximum Ratings may cause permanent damage to the device. These are stress ratings only and functional operation of the device at these or any other conditions beyond those indicated under Recommended Operating Conditions is not implied. Exposure to absolute-maximum-rated conditions for extended periods may affect device reliability.

(2) All voltages are with respect to GND unless otherwise noted. Currents are positive into and negative out of the specified terminal. See Packaging Section of the datasheet for thermal limitations and considerations of packages.

(3) These devices are sensitive to electrostatic discharge; follow proper device handling procedures.

(4) Maximum voltage on input pins is not restricted by the voltage on the VDD pin.

8.2 Handling Ratings

| MIN | MAX | UNIT | |||

|---|---|---|---|---|---|

| Tstg | Storage temperature range | –65 | 150 | °C | |

| V(ESD) | Electrostatic discharge | Human body model (HBM), per ANSI/ESDA/JEDEC JS-001, all pins(1) | –4000 | 4000 | V |

| Charged device model (CDM), per JEDEC specification JESD22-C101, all pins(2) | –1000 | 1000 | |||

(1) JEDEC document JEP155 states that 500-V HBM allows safe manufacturing with a standard ESD control process.

(2) JEDEC document JEP157 states that 250-V CDM allows safe manufacturing with a standard ESD control process.

8.3 Recommended Operating Conditions

over operating free-air temperature range (unless otherwise noted)| MIN | TYP | MAX | UNIT | |

|---|---|---|---|---|

| Supply voltage range, VDD | 4.5 | 12 | 18 | V |

| Operating junction temperature range | –40 | 140 | °C | |

| Input voltage, IN+ and IN- | 0 | 18 | V |

8.4 Thermal Information

| THERMAL METRIC | UCC27511 | UCC27512 | UNIT | |

|---|---|---|---|---|

| DBV | WSON(1) | |||

| 6 PINS | 6 PINS | |||

| θJA | Junction-to-ambient thermal resistance(2) | 217.8 | 85.6 | °C/W |

| θJCtop | Junction-to-case (top) thermal resistance(3) | 97.6 | 100.1 | |

| θJB | Junction-to-board thermal resistance(4) | 72.2 | 58.6 | |

| ψJT | Junction-to-top characterization parameter(5) | 8.6 | 7.5 | |

| ψJB | Junction-to-board characterization parameter(6) | 71.6 | 58.7 | |

| θJCbot | Junction-to-case (bottom) thermal resistance(7) | n/a | 23.7 | |

(1) For more information about traditional and new thermal metrics, see the IC Package Thermal Metrics application report, SPRA953.

(2) The junction-to-ambient thermal resistance under natural convection is obtained in a simulation on a JEDEC-standard, high-K board, as specified in JESD51-7, in an environment described in JESD51-2a.

(3) The junction-to-case (top) thermal resistance is obtained by simulating a cold plate test on the package top. No specific JEDEC-standard test exists, but a close description can be found in the ANSI SEMI standard G30-88.

(4) The junction-to-board thermal resistance is obtained by simulating in an environment with a ring cold plate fixture to control the PCB temperature, as described in JESD51-8.

(5) The junction-to-top characterization parameter, ψJT, estimates the junction temperature of a device in a real system and is extracted from the simulation data for obtaining RθJA, using a procedure described in JESD51-2a (sections 6 and 7).

(6) The junction-to-board characterization parameter, ψJB, estimates the junction temperature of a device in a real system and is extracted from the simulation data for obtaining RθJA, using a procedure described in JESD51-2a (sections 6 and 7).

(7) The junction-to-case (bottom) thermal resistance is obtained by simulating a cold plate test on the exposed (power) pad. No specific JEDEC standard test exists, but a close description can be found in the ANSI SEMI standard G30-88.

NOTE

Under identical power dissipation conditions, the DRS package will allow to maintain a lower die temperature than the DBV. θJA metric should be used for comparison of power dissipation capability between different packages (Refer to the Power Dissipation Section).

8.5 Electrical Characteristics

VDD = 12 V, TA = TJ = –40°C to 140°C, 1-µF capacitor from VDD to GND. Currents are positive into, negative out of the specified terminal.| PARAMETER | TEST CONDITION | MIN | TYP | MAX | UNIT | ||

|---|---|---|---|---|---|---|---|

| BIAS CURRENTS | |||||||

| IDD(off) | Startup current | VDD = 3.4 V | IN+ = VDD, IN– = GND | 40 | 100 | 160 | µA |

| IN+ = IN– = GND or IN+ = IN– = VDD | 25 | 75 | 145 | ||||

| IN+ = GND, IN– = VDD | 20 | 60 | 115 | ||||

| UNDERVOLTAGE LOCKOUT (UVLO) | |||||||

| VON | Supply start threshold | TA = 25°C | 3.91 | 4.20 | 4.5 | V | |

| TA = –40°C to 140°C | 3.70 | 4.20 | 4.65 | ||||

| VOFF | Minimum operating voltage after supply start | 3.45 | 3.9 | 4.35 | |||

| VDD_H | Supply voltage hysteresis | 0.2 | 0.3 | 0.5 | |||

| INPUTS (IN+, IN-) | |||||||

| VIN_H | Input signal high threshold | Output high for IN+ pin, Output low for IN– pin |

2.2 | 2.4 | V | ||

| VIN_L | Input signal low threshold | Output low for IN+ pin, Output high for IN– pin |

1.0 | 1.2 | |||

| VIN_HYS | Input signal hysteresis | 1.0 | |||||

| SOURCE/SINK CURRENT | |||||||

| ISRC/SNK | Source/sink peak current(1) | CLOAD = 0.22 µF, FSW = 1 kHz | -4/+8 | A | |||

| OUTPUTS (OUTH, OUTL, OUT) | |||||||

| VDD-VOH | High output voltage | VDD = 12 V IOUTH = -10 mA |

50 | 90 | mV | ||

| VDD = 4.5 V IOUTH = -10 mA |

60 | 130 | |||||

| VOL | Low output voltage | VDD = 12 IOUTL = 10 mA |

5 | 6.5 | |||

| VDD = 4.5 V IOUTL = 10 mA |

5.5 | 10 | |||||

| ROH | Output pull-up resistance(3) | VDD = 12 V IOUTH = -10 mA |

5.0 | 7.5 | Ω | ||

| VDD = 4.5 V IOUTH = -10 mA |

5.0 | 11.0 | |||||

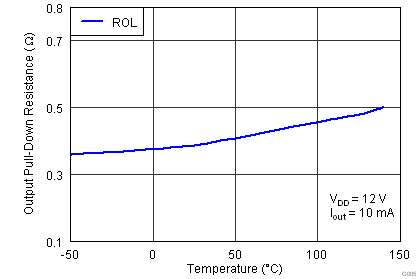

| ROL | Output pull-down resistance | VDD = 12 V IOUTL = 10 mA |

0.375 | 0.650 | |||

| VDD = 4.5 V IOUTL = 10 mA |

0.45 | 0.750 | |||||

(1) Ensured by Design.

(3) ROH represents on-resistance of P-Channel MOSFET in pullup structure of the output stage of the UCC27511 and UCC27512.

Switching Characteristics

over operating free-air temperature range (unless otherwise noted)| PARAMETER | TEST CONDITIONS | MIN | TYP | MAX | UNIT | |

|---|---|---|---|---|---|---|

| tR | Rise time(2) | VDD = 12 V CLOAD = 1.8 nF, connected to OUTH and OUTL pins tied together |

8 | 12 | ns | |

| VDD = 4.5 V CLOAD = 1.8 nF |

16 | 22 | ||||

| tF | Fall time(2) | VDD = 12 V CLOAD = 1.8 nF, connected to OUTH and OUTL pins tied together |

7 | 11 | ||

| VDD=4.5V CLOAD = 1.8 nF |

7 | 11 | ||||

| tD1 | IN+ to output propagation delay(2) | VDD = 12 V 5-V input pulse CLOAD = 1.8 nF, connected to OUTH and OUTL pins tied together |

4 | 13 | 23 | |

| VDD = 4.5 V 5-V input pulse CLOAD = 1.8 nF, connected to OUTH and OUTL pins tied together |

4 | 15 | 26 | |||

| tD2 | IN- to output propagation delay(2) | VDD = 12 V CLOAD = 1.8 nF, connected to OUTH and OUTL pins tied together |

4 | 13 | 23 | |

| VDD = 4.5 V CLOAD = 1.8 nF, connected to OUTH and OUTL pins tied together |

4 | 19 | 30 | |||

(PWM Input to IN+ Pin (IN– Pin Tied to GND), Output Represents OUTH And OUTL Pins Tied Together in the UCC27511)

Figure 1. Noninverting Configuration

(PWM Input to IN– Pin (IN+ Pin Tied to VDD), Output Represents OUTH and OUTL Pins Tied Together in the UCC27511)

Figure 2. Inverting Configuration

(Enable and Disable Signal Applied to IN+ Pin, PWM Input to IN– Pin, Output Represents OUTH and OUTL Pins Tied Together in the UCC27511)

Figure 3. Enable and Disable Function Using IN+ Pin

(Enable and Disable Signal Applied to IN– Pin, PWM Input To IN+ Pin, Output Represents OUTH and OUTL Pins Tied Together in the UCC27511)

Figure 4. Enable and Disable Function Using IN– Pin

8.6 Typical Characteristics

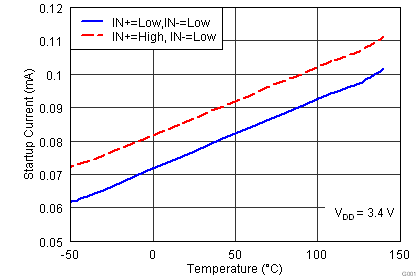

Figure 5. Start-Up Current vs Temperature

Figure 5. Start-Up Current vs Temperature

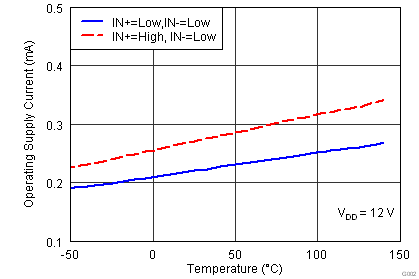

Figure 7. Supply Current vs Temperature (Output In DC On/Off Condition)

Figure 7. Supply Current vs Temperature (Output In DC On/Off Condition)

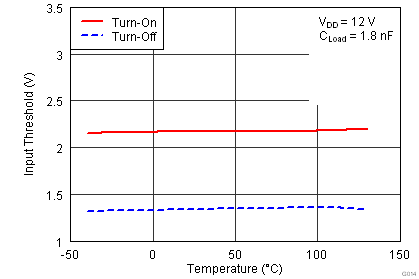

Figure 9. Input Threshold vs Temperature

Figure 9. Input Threshold vs Temperature

Figure 11. Output Pulldown Resistance vs Temperature

Figure 11. Output Pulldown Resistance vs Temperature

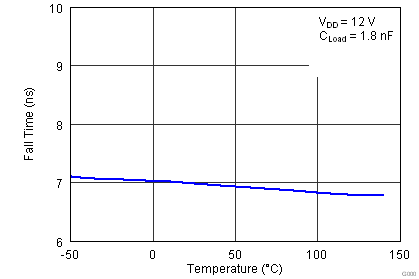

Figure 13. Fall Time vs Temperature

Figure 13. Fall Time vs Temperature

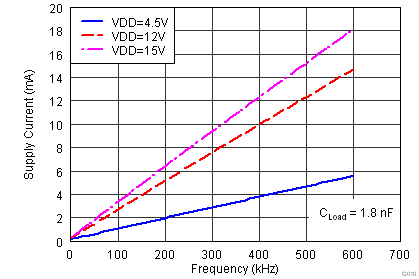

Figure 15. Operating Supply Current vs Frequency

Figure 15. Operating Supply Current vs Frequency

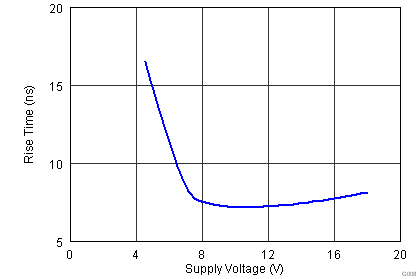

Figure 17. Rise Time vs Supply Voltage

Figure 17. Rise Time vs Supply Voltage

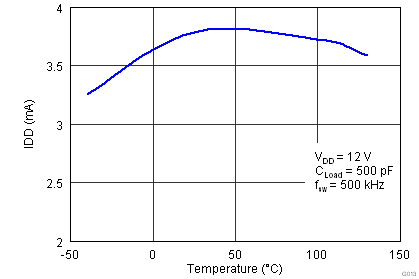

Figure 6. Operating Supply Current vs Temperature (Output Switching)

Figure 6. Operating Supply Current vs Temperature (Output Switching)

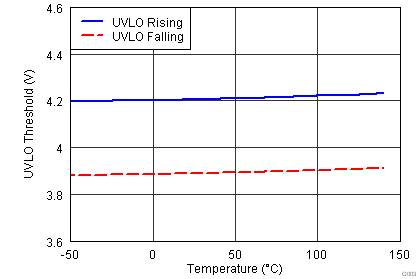

Figure 8. UVLO Threshold Voltage vs Temperature

Figure 8. UVLO Threshold Voltage vs Temperature

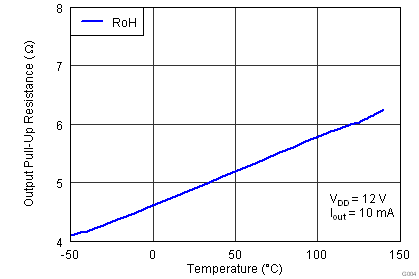

Figure 10. Output Pullup Resistance vs Temperature

Figure 10. Output Pullup Resistance vs Temperature

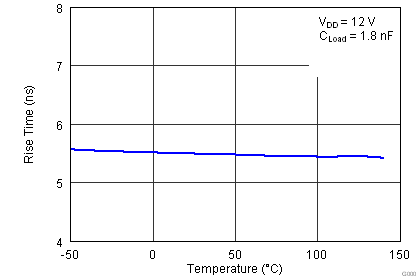

Figure 12. Rise Time vs Temperature

Figure 12. Rise Time vs Temperature

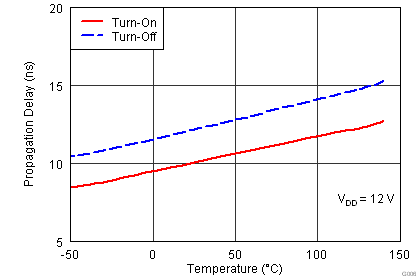

Figure 14. Input to Output Propagation Delay vs Temperature

Figure 14. Input to Output Propagation Delay vs Temperature

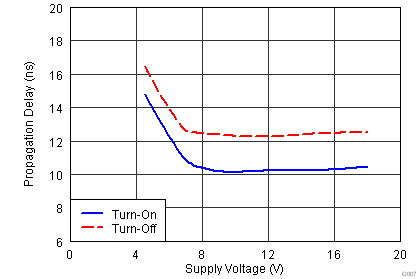

Figure 16. Propagation Delays vs Supply Voltage

Figure 16. Propagation Delays vs Supply Voltage

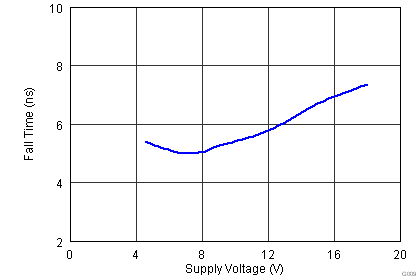

Figure 18. Fall Time vs Supply Voltage

Figure 18. Fall Time vs Supply Voltage