SNOS515F October 2000 – August 2015 LM8272

PRODUCTION DATA.

- 1Features

- 2Applications

- 3Description

- 4Revision History

- 5Pin Configuration and Functions

- 6Specifications

-

7Application and Implementation

- 7.1 Block Diagram and Operational Description A) Input Stage:

- 7.2 B) Output Stage:

- 7.3 C) Output Voltage Swing Close to V−:

- 7.4 Driving Capactive Loads:

- 7.5 Estimating the Output Voltage Swing

- 7.6 Output Short Circuit Current and Dissipation Issues:

- 7.7 Other Application Hints:

- 7.8 LM8272 Advantages:

- 8Device and Documentation Support

- 9Mechanical, Packaging, and Orderable Information

7 Application and Implementation

7.1 Block Diagram and Operational Description

A) Input Stage:

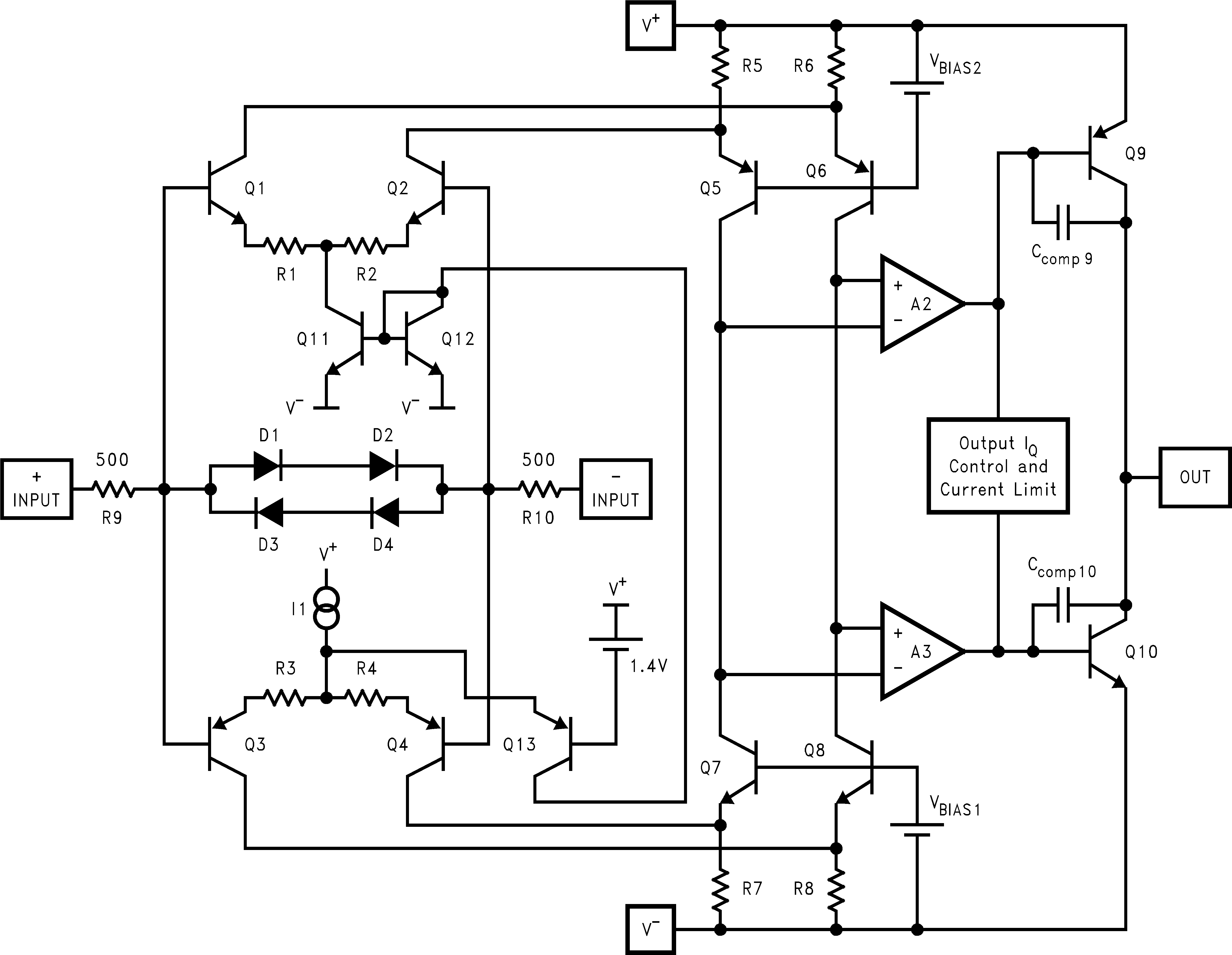

As seen in Figure 35, the input stage consists of two distinct differential pairs (Q1-Q2 and Q3-Q4) in order to accommodate the full Rail-to-Rail input common mode voltage range. The voltage drop across R5, R6, R7 and R8 is kept to less than 200 mV in order to allow the input to exceed the supply rails. Q13 acts as a switch to steer current away from Q3-Q4 and into Q1-Q2, as the input increases beyond 1.4 of V+. This in turn shifts the signal path from the bottom stage differential pair to the top one and causes a subsequent increase in the supply current.

In transitioning from one stage to another, certain input stage parameters (VOS, Ib, IOS, en, and in) are determined based on which differential pair is “on” at the time. Input Bias current, Ib, will change in value and polarity as the input crosses the transition region. In addition, parameter such as PSRR and CMRR which involve the input offset voltage will also be effected by changes in VCM across the differential pair transition region.

Figure 35. Simplified Schematic Diagram

Figure 35. Simplified Schematic Diagram

The input stage is protected with the combination of R9-R10 and D1, D2, D3 and D4 against differential input over-voltages. This fault condition could otherwise harm the differential pairs or cause offset voltage shift in case of prolonged over voltage. As shown in Figure 36, if this voltage reaches approximately ±1.4V at 25°C, the diodes turn on and current flow is limited by the internal series resistors (R9 and R10). The Absolute Maximum Rating of ±10V differential on VIN still needs to be observed. With temperature variation, the point were the diodes turn on will change at the rate of 5mV/°C

Figure 36. Input Stage Current vs. Differential Input Voltage

Figure 36. Input Stage Current vs. Differential Input Voltage

7.2 B) Output Stage:

The output stage (see Figure 35) is comprised of complimentary NPN and PNP common-emitter stages to permit voltage swing to within a Vce(sat) of either supply rail. Q9 supplies the sourcing and Q10 supplies the sinking current load. Output current limiting is achieved by limiting the Vce of Q9 and Q10. Using this approach to current limiting alleviates the drawback to the conventional scheme which requires one Vbe reduction in output swing.

The frequency compensation circuit includes Miller capacitors from collector to base of each output transistor (see Figure 35, Ccomp9 and Ccomp10). At light capacitive loads, the high frequency gain of the output transistors is high, and the Miller effect increases the effective value of the capacitors thereby stabilizing the Op Amp. Large capacitive loads greatly decrease the high frequency gain of the output transistors thus lowering the effective internal Miller capacitance - the internal pole frequency increases at the same time a low frequency pole is created at the Op Amp output due to the large load capacitor. In this fashion, the internal dominant pole compensation, which works by reducing the loop gain to less than 0dB when the phase shift around the feedback loop is more than 180°, varies with the amount of capacitive load and becomes less dominant when the load capacitor has increased enough. Hence the Op Amp is very stable even at high values of load capacitance resulting in the uncharacteristic feature of stability under all capacitive loads.

7.3 C) Output Voltage Swing Close to V−:

The LM8272's output stage design allows voltage swings to within millivolts of either supply rail for maximum flexibility and improved useful range. Because of this design architecture, as can be seen from Figure 35 diagram, with Output approaching either supply rail, either Q9 or Q10 Collector-Base junction reverse bias will decrease. With output less than a Vbe from either rail, the corresponding output transistor operates near saturation. In this mode of operation, the transistor will exhibit higher junction capacitance and lower ft which will reduce Phase Margin. With the Noise Gain (NG = 1 + Rf/Rg, Rf & Rg are external gain setting resistors) of 2 or higher, there is sufficient Phase Margin that this reduction (in Phase Margin) is of no consequence. However, with lower Noise Gain (<2) and with less than 150mV voltage to the supply rail, if the output loading is light, the Phase Margin reduction could result in unwanted oscillations.

In the case of the LM8272, due to inherent architectural specifics, the oscillation occurs only with respect to Q10 when output swings to within 150mV of V−. However, if Q10 collector current is larger than its idle value of a few microamps, the Phase Margin loss becomes insignificant. In this case, 300µA is the required Q10 collector current to remedy this situation. Therefore, when all the aforementioned critical conditions are present at the same time (NG < 2, VOUT < 150mV from supply rails, & output load is light) it is possible to ensure stability by adding a load resistor to the output to provide the necessary Q10 minimum Collector Current (300µA).

For 12V (or ±6V) operation, for example, add a 39kΩ resistor from the output to V+ to cause 300µA output sinking current and ensure stability. This is equivalent to about 15% increase in total quiescent power dissipation.

7.4 Driving Capactive Loads:

The LM8272 is specifically designed to drive unlimited capacitive loads without oscillations (see Figure 25). In addition, the output current handling capability of the device allows for good slewing characteristics even with large capacitive loads (Settling Time and Slew Rate vs. Cap Load plot). The combination of these features is ideal for applications such as TFT flat panel buffers, A/D converter input amplifiers, etc.

However, as in most Op Amps, addition of a series isolation resistor between the Op Amp and the capacitive load improves the settling and overshoot performance.

Output current drive is an important parameter when driving capacitive loads. This parameter will determine how fast the output voltage can change. Referring to Figure 25, two distinct regions can be identified. Below about 10,000pF, the output Slew Rate is solely determined by the Op Amp's compensation capacitor value and available current into that capacitor. Beyond 10nF, the Slew Rate is determined by the Op Amp's available output current. An estimate of positive and negative slew rates for loads larger than 100nF can be made by dividing the short circuit current value by the capacitor.

7.5 Estimating the Output Voltage Swing

It is important to keep in mind that the steady state output current will be less than the current available when there is an input overdrive present. For steady state conditions, Figure 37 and Figure 38 plots can be used to predict the output swing. These plots also show several load lines corresponding to loads tied between the output and ground. In each case, the intersection of the device plot at the appropriate temperature with the load line would be the typical output swing possible for that load. For example, a 600-Ω load can accommodate an output swing to within 100mV of V− and to 250mV of V+ (VS = ±5V) corresponding to a typical 9.65VPP unclipped swing.

Figure 37. Steady State Output Sourcing Characteristics with Load Lines

Figure 37. Steady State Output Sourcing Characteristics with Load Lines

Figure 38. Steady State Output Sinking Characteristics with Load Lines

Figure 38. Steady State Output Sinking Characteristics with Load Lines

7.6 Output Short Circuit Current and Dissipation Issues:

The LM8272 output stage is designed for maximum output current capability. Even though momentary output shorts to ground and either supply can be tolerated at all operating voltages, longer lasting short conditions can cause the junction temperature to rise beyond the absolute maximum rating of the device, especially at higher supply voltage conditions. Below supply voltage of 6V, output short circuit condition can be tolerated indefinitely.

With the Op Amp tied to a load, the device power dissipation consists of the quiescent power due to the supply current flow into the device, in addition to power dissipation due to the load current. The load portion of the power itself could include an average value (due to a DC load current) and an AC component. DC load current would flow if there is an output voltage offset, or if the output AC average current is non-zero, or if the Op Amp operates in a single supply application where the output is maintained somewhere in the range of linear operation. Therefore:

| PAC = See Table 1 below | (AC Load Power) |

where:

- IS: Supply Current

- VS: Total Supply Voltage (V+ - V−)

- VO: Average Output Voltage

- Vr: V+ for sourcing and V− for sinking current

Table 1 below shows the maximum AC component of the load power dissipated by the Op Amp for standard Sinusoidal, Triangular, and Square Waveforms:

Table 1. Normalized AC Power Dissipated in the Output Stage for Standard Waveforms

| PAC (W.Ω/V2) | ||

|---|---|---|

| SINUSOIDAL | TRIANGULAR | SQUARE |

| 50.7 × 10−3 | 46.9 × 10−3 | 62.5 × 10−3 |

The table entries are normalized to VS2/RL. To figure out the AC load current component of power dissipation, simply multiply the table entry corresponding to the output waveform by the factor VS2/RL. For example, with ±12V supplies, a 600Ω load, and triangular waveform power dissipation in the output stage is calculated as:

7.7 Other Application Hints:

The use of supply decoupling is mandatory in most applications. As with most relatively high speed/high output current Op Amps, best results are achieved when each supply line is decoupled with two capacitors; a small value ceramic capacitor (∼0.01µF) placed very close to the supply lead in addition to a large value Tantalum or Aluminum (> 4.7µF). The large capacitor can be shared by more than one device if necessary. The small ceramic capacitor maintains low supply impedance at high frequencies while the large capacitor will act as the charge “bucket” for fast load current spikes at the Op Amp output. The combination of these capacitors will provide supply decoupling and will help keep the Op Amp oscillation free under any load.

7.8 LM8272 Advantages:

Compared to other Rail-to-Rail Input/Output devices, the LM8272 offers several advantages such as:

- Improved cross over distortion

- Nearly constant supply current throughout the output voltage swing range and close to either rail.

- Nearly constant Unity gain frequency (fu) and Phase Margin (Phim) for all operating supplies and load conditions.

- No output phase reversal under input overload condition.