-

TPS54A20 8-V to 14-V Input, 10-A, up to 10-MHz SWIFT Step Down Converter

- 1 Features

- 2 Applications

- 3 Description

- 4 Revision History

- 5 Pin Configuration and Functions

- 6 Specifications

-

7 Detailed Description

- 7.1 Overview

- 7.2 Functional Block Diagram

- 7.3

Feature Description

- 7.3.1 Frequency Selection

- 7.3.2 External Clock Syncronization

- 7.3.3 Adjusting the Output Voltage

- 7.3.4 Soft Start

- 7.3.5 Startup into Pre-biased Outputs

- 7.3.6 Power Good (PGOOD)

- 7.3.7 Overcurrent Protection

- 7.3.8 Light Load Operation

- 7.3.9 Output Undervoltage/Overvoltage Protection

- 7.3.10 Input Undervoltage/Overvoltage Lockout

- 7.3.11 Enable and Adjusting Undervoltage Lockout

- 7.3.12 Series Capacitor Monitoring

- 7.3.13 Thermal Shutdown

- 7.3.14 Phase A Power Stage

- 7.3.15 Phase B Power Stage

- 7.3.16 Internal Gate Drive Regulator

- 7.3.17 Voltage Feed Forward

- 7.3.18 Internal Oscillator

- 7.3.19 Pulse Frequency Detector

- 7.3.20 On-Time Generator

-

8 Application and Implementation

- 8.1 Application Information

- 8.2

Typical Application

- 8.2.1 Design Requirements

- 8.2.2

Detailed Design Procedure

- 8.2.2.1 Output Voltage

- 8.2.2.2 Switching Frequency

- 8.2.2.3 On-Time

- 8.2.2.4 Inductor Selection

- 8.2.2.5 Output Capacitor Selection

- 8.2.2.6 Input Capacitor Selection

- 8.2.2.7 Series Capacitor Selection

- 8.2.2.8 Soft-Start Time Selection

- 8.2.2.9 Bootstrap Capacitor Selection

- 8.2.2.10 Gate Drive Capacitor Selection

- 8.2.2.11 Under Voltage Lockout Set Point

- 8.2.2.12 Current Limit Selection

- 8.2.3 Application Curves

- 9 Power Supply Recommendations

- 10Layout

- 11Device and Documentation Support

- 12Mechanical, Packaging, and Orderable Information

- IMPORTANT NOTICE

パッケージ・オプション

デバイスごとのパッケージ図は、PDF版データシートをご参照ください。

メカニカル・データ(パッケージ|ピン)

- RNJ|20

サーマルパッド・メカニカル・データ

発注情報

TPS54A20 8-V to 14-V Input, 10-A, up to 10-MHz SWIFT Step Down Converter

1 Features

- Two-phase, Synchronous Series Capacitor Buck Converter

- Automatic Current Balancing Between Phases

- 2-MHz to 5-MHz Per Phase Switching Frequency

- 14-ns Minimum On-Time

- 0.51-V to 2-V Output Voltage Range with ±0.5% Feedback Reference Voltage

- Input Overvoltage Lockout for 17-V Surge Protection

- Adjustable Current Limit with Auto Restart (Hiccup)

- Synchronizes to an External Clock

- Fixed Frequency in Steady State

- Adaptive On-Time Control

- Internal Feedback Loop Compensation

- Internal Gate Drive LDO with External Supply Option

- EN Pin Allowing for Adjustable Input UVLO

- Selectable Soft-Start Time

- Monotonic Startup with Pre-biased Output

- Output Power Good Indicator (Open Drain)

- Output Overvoltage/Undervoltage Protection

2 Applications

- Telecom, base station, and communications equipment

- Storage, SSD, DDR memory, switches, hubs, routers, and other networking equipment

- Low profile/Backside board mounting (< 2 mm height)

3 Description

The TPS54A20 is a two-phase, synchronous series capacitor buck converter designed for small size, low voltage applications from a 12-V input rail. This topology uniquely merges a switched capacitor circuit with a two phase buck converter. Advantages include automatic current balancing between the inductors, lower switching losses which enable high frequency (HF) operation, and voltage step-down through the series capacitor. Small, low profile inductors used with the TPS54A20 significantly reduce total solution area and height. An adaptive on-time control architecture provides fast transient response and accurate voltage regulation at up to 10-MHz operating frequency. Fixed frequency operation during steady state is maintained through the use of a phase lock loop (PLL) to lock switching signals to a reference oscillator.

Device Information(1)

| PART NUMBER | PACKAGE | BODY SIZE (NOM) |

|---|---|---|

| TPS54A20 | VQFN (20 pins) | 3.5 mm x 4 mm |

- For all available packages, see the orderable addendum at the end of the datasheet.

Simplified Schematic

Efficiency vs Load Current

4 Revision History

Changes from * Revision (December 2015) to A Revision

- Changed the device status to Production data. Go

5 Pin Configuration and Functions

Pin Functions

| PIN | I/O(1) | DESCRIPTION | |

|---|---|---|---|

| NAME | NO. | ||

| AGND | 1 | G | Analog signal ground of the IC. AGND should be connected to PGND and VG- at a single point on PCB (e.g. underneath the IC). |

| BOOTA | 8 | S | Bootstrap capacitor node for phase A high-side MOSFET gate driver. Connect the bootstrap capacitor from this pin to the SCAP pin (pin 9). |

| BOOTB | 10 | S | Bootstrap capacitor node for phase B high-side MOSFET gate driver. Connect the bootstrap capacitor from this pin to the SWB pin. |

| EN | 4 | I | Enable pin. Floating this pin will enable the IC. Pull below 1.23V to enter shutdown mode. Can also be used to adjust the input undervoltage lockout above 8 V with two resistors. |

| FB | 18 | I | Feedback pin for voltage regulation. Connect this pin to the center tap of a resistor divider to set the output voltage. |

| ILIM | 5 | I | Current limit programming pin. A resistor between this pin and ground sets the current limit. If no resistor is included, the default load current limit is 15 A. |

| NC | 11 | No connect. This pin is not electrically connected to the IC and is included for board level reliability (BLR) purposes. Connect this pin to the SCAP trace. | |

| PGND | 2 | G | Power ground of the IC. PGND should be connected to AGND and VG- at a single point on PCB (e.g. underneath the IC). Thermal vias to internal ground planes should be added beneath this pin. |

| PGOOD | 15 | O | Power good indicator. This pin is an open-drain output and will assert low if the output voltage is greater than ±5% away from the desired value or due to thermal shutdown, over-voltage/under-voltage, EN shutdown, or during soft start. A pull-up resistor can be connected between PGOOD and VG+ or an external logic supply pin. |

| SCAP | 9,20 | O | Series capacitor pin. Connect a ceramic capacitor from pin 20 to the SWA pin. |

| SS/FSEL | 6 | I | Soft start/frequency select pin. Connect a resistor from this pin to ground to set the soft-start time and the switching frequency. If no resistor is provided, the default setting of 4MHz oscillator frequency and 512µs soft start time is used. |

| SWA | 13 | O | Switching node for phase A. Connect an inductor from this pin to the output capacitors. |

| SWB | 12 | O | Switching node for phase B. Connect an inductor from this pin to the output capacitors. |

| SYNC | 14 | I | External clock synchronization pin. An external clock signal can be connected to this pin to synchronize the oscillator frequency (within ±10% of the nominal frequency set via SS/FSEL). |

| TON | 19 | I | On-time selection. An external resistor from this pin to the AGND pin programs the nominal on-time of the high side switches. |

| VG+ | 16 | S | Gate driver positive supply pin. Connect a bypass capacitor from this pin to VG-. To improve converter efficiency, the internal regulator can be overridden by connecting an external 5V supply to this pin. This supply rail also provides power to the control circuitry. |

| VG- | 17 | G | Gate driver supply return pin. VG- should be connected to PGND and AGND at a single point on PCB (e.g. underneath the IC). |

| VGA | 7 | S | High side phase A gate driver supply pin. Connect a bypass capacitor from this pin to ground. |

| VIN | 3 | I | The power input pin to the IC. Connect VIN to a supply voltage between 8 V and 14 V. |

6 Specifications

6.1 Absolute Maximum Ratings

over operating free-air temperature range (unless otherwise noted) (1)| MIN | MAX | UNIT | |||

|---|---|---|---|---|---|

| Input Voltage | Power Conversion, VIN | DC w.r.t. PGND, switching | –0.3 | 15 | V |

| DC w.r.t. PGND, non-switching | –0.3 | 17 | |||

| Bootstrap, V(BOOTA) | DC with respect to PGND | –0.3 | 22 | V | |

| DC with respect to SCAP | 6 | V | |||

| Bootstrap, V(BOOTB) | DC with respect to PGND | –0.3 | 14 | V | |

| DC with respect to SWB | 6 | V | |||

| Bias Supply, VG | DC with respect to PGND | –0.3 | 6 | V | |

| Series Capacitor Node Voltage, V(SCAP) | DC with respect to PGND | –0.3 | 16 | V | |

| Switch Node Voltage, V(SWA, SWB) | DC with respect to PGND | –1 | 9 | ||

| Pulse < 10 ns | –4 | 14 | |||

| Feedback, V(FB) | –0.3 | 3 | V | ||

| Output Voltage | Bias Supply, V(VGA) | DC with respect to PGND | –0.3 | 15 | V |

| Voltage | Enable Voltage, V(EN) | –0.3 | 7 | V | |

| Soft Start/Freq. Select, V(SS/FSEl) | –0.3 | 3 | |||

| Power Good Voltage, V(PGOOD) | –0.3 | 6 | |||

| External Sync Clock Voltage, V(SYNC) | –0.3 | 6 | |||

| Current Limit/Mode Select, V(ILIM) | –0.3 | 3 | |||

| On Time Pin Voltage, V(TON) | –0.3 | 3 | |||

| Input Current | Power Conversion, I(VIN) | 6 | A | ||

| Bias Supply, I(VG) | 100 | mA | |||

| Output Current | Switch Node A, I(SWA) | Current Limit | A | ||

| Switch Node B, I(SWB) | Current Limit | A | |||

| Operating Junction Temperature, TJ | –40 | 125 | °C | ||

| Storage temperature, Tstg | –65 | 150 | °C | ||

6.2 ESD Ratings

| VALUE | UNIT | |||

|---|---|---|---|---|

| V(ESD) | Electrostatic discharge | Human body model (HBM), per ANSI/ESDA/JEDEC JS-001, all pins(1) | ±2000 | V |

| Charged device model (CDM), per JEDEC specification JESD22-C101, all pins(2) | ±500 | |||

6.3 Recommended Operating Conditions

over operating free-air temperature range (unless otherwise noted)| MIN | NOM | MAX | UNIT | ||

|---|---|---|---|---|---|

| VIN | Input Voltage | 8 | 14 | V | |

| VOUT | Output Voltage | 0.5 | VIN/5 | V | |

| IOUT | Output Current | 0 | 10 | A | |

| TJ | Junction Temperature | -40 | 125 | °C | |

6.4 Thermal Information

| THERMAL METRIC(1) | RNJ | UNIT | |

|---|---|---|---|

| 20 PINS | |||

| RθJA | Junction-to-ambient thermal resistance | 25(2) | °C/W |

| RθJC(top) | Junction-to-case (top) thermal resistance | 13.4 | °C/W |

| RθJB | Junction-to-board thermal resistance | 4.9 | °C/W |

| ψJT | Junction-to-top characterization parameter | 0.2 | °C/W |

| ψJB | Junction-to-board characterization parameter | 4.7 | °C/W |

| RθJC(bot) | Junction-to-case (bottom) thermal resistance | 2.0 | °C/W |

6.5 Electrical Characteristics

over operating free-air temperature range (unless otherwise noted)| PARAMETER | TEST CONDITIONS | MIN | TYP | MAX | UNIT | |

|---|---|---|---|---|---|---|

| SUPPLY VOLTAGE (VIN PIN) | ||||||

| VIN | VIN Operating | 8 | 12 | 14 | V | |

| VIN Input UVLO Voltage | VIN rising | 7.4 | 7.65 | 7.95 | V | |

| VIN UVLO hysteresis | 250 | mV | ||||

| VIN Input OVLO Voltage | VIN rising | 15.4 | 15.8 | V | ||

| VIN falling | 14.1 | 14.8 | V | |||

| VIN OVLO hysteresis | 600 | mV | ||||

| Shutdown | EN < 0.4 V, VIN = 12 V, TA = 25°C | 47 | µA | |||

| IQ | Operating into VIN | FB = 0.53 V, VIN = 12 V, TA = 25°C | 6 | mA | ||

| ENABLE (EN PIN) | ||||||

| Enable threshold | 1.17 | 1.23 | 1.27 | V | ||

| Input current | Enable threshold + 50 mV | –4 | µA | |||

| Enable threshold – 50 mV | –1 | µA | ||||

| VOLTAGE REFERENCE | ||||||

| Voltage Reference | TA = 25°C | 0.5054 | 0.508 | 0.5106 | V | |

| –40°C < TJ < 125°C | 0.5029 | 0.508 | 0.5131 | V | ||

| FREQUENCY | ||||||

| fOSC | Oscillator Frequency | R(SS/FSEL) = Open, 71.5 kΩ, or 48.7 kΩ |

3.6 | 4 | 4.4 | MHz |

| R(SS/FSEL) = Short or 35.7 kΩ | 6.3 | 7 | 7.7 | MHz | ||

| R(SS/FSEL) = 21.5 kΩ, 15.4 kΩ, or 8.66 kΩ |

9 | 10 | 11 | MHz | ||

| SYNC | ||||||

| Minimum Input Clock Pulsewidth | 20 | ns | ||||

| SYNC high threshold | 2 | V | ||||

| SYNC low threshold | 0.8 | V | ||||

| Frequency sync range | ±10 | % nominal | ||||

| Last SYNC falling/rising edge to return to resistor timing mode if SYNC is not present | 10 MHz: 400 ns 7 MHz: 571 ns 4 MHz : 1 µs |

4 | Cycles | |||

| LOW-SIDE A MOSFET | ||||||

| On resistance | VG = 5 V, Measured at pins | 6.8 | 10.5 | mΩ | ||

| LOW-SIDE B MOSFET | ||||||

| On resistance | VG = 5 V, Measured at pins | 9.3 | 14.8 | mΩ | ||

| HIGH-SIDE MOSFETS | ||||||

| On resistance | Vgs = 5 V, Measured at pins | 27 | 50 | mΩ | ||

| SW rise time 10% to 90% | VIN = 12 V | 2 | ns | |||

| SW fall time 90% to 10% | VIN = 12 V | 2 | ns | |||

| CURRENT LIMIT | ||||||

| Peak Switch LSA Current Limit | ~15A Load Trip, R(ILIM) = Open | 12.7 | 16.3 | 19.9 | A | |

| ~11.25A Load Trip, R(ILIM) = 47 kΩ | 9.9 | 12.7 | 15.5 | |||

| Peak Switch LSB Current Limit | ~15A Load Trip, R(ILIM) = Open | 6.8 | 8.7 | 10.6 | A | |

| ~11.25A Load Trip, R(ILIM) = 47 kΩ | 5.3 | 6.8 | 8.3 |

|||

| Overcurrent protection scheme | Hiccup | |||||

| OCP cycle count to trip fault | 3 | Cycles | ||||

| Fault hiccup wait time | 10 MHz: 13.1 ms 7 MHz: 18.7 ms 4 MHz: 32.8 ms |

131,072 | Cycles | |||

| INTERNAL REGULATOR (VG LDO) | ||||||

| Output Voltage | 0 mA ≤ IVG ≤ 100 mA | 4.4 | 4.8 | 5 | V | |

| Current Limit | 100 | 140 | mA | |||

| Nominal Operating Current | Fosc = 10 MHz, ILOAD = 10A | 60 | mA | |||

| DYNAMIC REGULATOR (VGA LDO) | ||||||

| Output Voltage | 15 | V | ||||

| VIN = 12 V | 10.5 | V | ||||

| SERIES CAP MONITOR | ||||||

| Low Voltage Fault Trip | 35 | 38 | %VIN | |||

| Nominal Voltage | 50 | |||||

| High Voltage Fault Trip | 62 | 65 | ||||

| Capacitor Precharge Current | 5.5 | 10 | 14.5 | mA | ||

| POWER GOOD | ||||||

| VFB threshold | VFB falling (Fault), UVP | 90 | %VREF | |||

| VFB rising (Good) | 95 | |||||

| VFB rising (Fault), OVP | 110 | |||||

| VFB falling (Good) | 105 | |||||

| PGOOD sink current | V(PGOOD) = 0.4 V | 2.7 | mA | |||

| PGOOD pin leakage current | VFB = VREF, V(PGOOD)= 5 V | 1 | μA | |||

| Minimum VIN for valid PGOOD | V(PGOOD) ≤ 0.5 V at 100 µA | 1.2 | 2.75 | V | ||

| THERMAL SHUTDOWN | ||||||

| Thermal shutdown set threshold | 135 | °C | ||||

| Thermal shutdown hysteresis | 20 | °C | ||||

| Thermal shutdown hiccup time | 10 MHz: 13.1 ms 7 MHz: 18.7 ms 4 MHz: 32.8 ms |

131,072 | Cycles | |||

6.6 Timing Requirements

| MIN | NOM | MAX | UNIT | ||

|---|---|---|---|---|---|

| ENABLE (EN PIN) | |||||

| Enable to Start Switching time | 1 µF series cap, VIN = 12V | 625 | µs | ||

| SYNC | |||||

| Lock in time | 30 | µs | |||

| HIGH-SIDE MOSFETS | |||||

| SW minimum ON pulse width | 14 | ns | |||

| SW minimum OFF pulse width | 10 | ns | |||

| Non-Overlap Time between HS FET Off and LS FET On (deadtime) | Fsw = 5 MHz, VIN = 12 V | 3 | ns | ||

| Non-Overlap Time between LS FET Off and HS FET On (deadtime) | 3 | ns | |||

6.7 Typical Characteristics

VIN = 12 V, VOUT = 1.2 V, TA = 25 ºC, unless otherwise noted.

| EN = Threshold + 50 mV |

| fsw = 2 MHz per phase | 3.2 x 2.5 x 1.2 mm inductors |

| fsw = 2 MHz per phase | 3.2 x 2.5 x 1.2 mm inductors | No air flow |

| 1 Ω Load | fsw = 2 MHz per phase | |

| 40 ms/div |

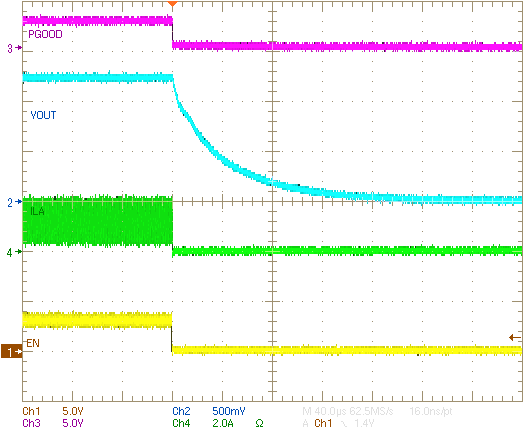

| 5 Ω Load | fsw = 2 MHz per phase | 40 µs/div |

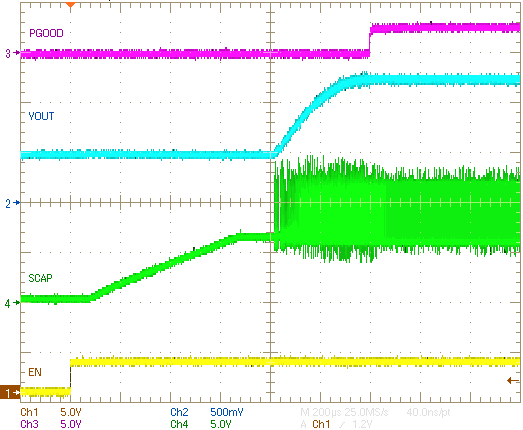

| Series capacitance = 1 µF | fsw = 2 MHz per phase | |

| 2 ms/div |

| 75 Ω Load | 4 ms/div |

| fsw = 2 MHz per phase | 2 µs/div |

| fsw = 2 MHz per phase | 0 A load | 200 ns/div |

| Room temperature | 10 A load | No air flow |

| fsw = 2 MHz per phase | 3.2 x 2.5 x 1.2 mm inductors | Four layer board |

| EN = 0 V |

| EN = Threshold - 50 mV |

| FB = 0.53 V (non-switching) |

| fsw = 2 MHz per phase | External VG+ | 3.2 x 2.5 x 1.2 mm inductors |

| Series capacitance = 1 µF | fsw = 2 MHz per phase | |

| 200 µs/div |

| Series capacitance = 1 µF | fsw = 2 MHz per phase | |

| 200 µs/div |

| 0 A Load | fsw = 2 MHz per phase | 400 µs/div |

| 0.5 Ω Load | 20 µs/div |

| 4 ms/div |

| 3.2 MHz SYNC clock |

7 Detailed Description

7.1 Overview

The TPS54A20 is a 14-V, 10-A, synchronous series capacitor step-down (buck) converter with four integrated N-channel MOSFETs. To improve performance during line and load transients the TPS54A20 implements an adaptive on-time control scheme which does not require external compensation components. The selectable switching frequencies are 2 MHz, 3.5 MHz, or 5 MHz per phase which allows for efficiency and size optimization when selecting the output filter components. A resistor to ground on the TON pin sets the nominal high side switch on-time based on the desired output voltage.

The TPS54A20 contains an internal oscillator for steady-state, fixed frequency operation that is set through the SS/FSEL pin. The controller operates at twice the per phase switching frequency (that is, 4 MHz, 7 MHz, or 10 MHz) and the oscillator is set accordingly. An external synchronization clock can also be provided via the SYNC pin.

The TPS54A20 starts up safely into loads with pre-biased outputs (non-zero volts at startup). The device implements an internal under voltage lockout (UVLO) feature on the VIN pin with a nominal starting voltage of 7.65 V. The total operating current for the TPS54A20 is approximately 6 mA when not switching and under no load. When the TPS54A20 is disabled by pulling the EN pin low, the supply current is typically less than 50 µA.

The integrated MOSFETs allow for high-efficiency, high-density power supply designs with continuous output currents up to 10 A. The MOSFETs are sized to optimize efficiency for low duty cycle applications operating around 2 MHz per phase switching frequency.

The TPS54A20 reduces the external component count by integrating the bootstrap recharge circuit. Capacitors connected between the BOOTA/BOOTB and SCAP/SWB pins (respectively) supply the gate drive voltage for the integrated high-side MOSFETs. The output voltage can be stepped down to as low as the 0.5-V voltage reference (VREF).

The TPS54A20 has a power good comparator (PGOOD) which monitors the output voltage through the FB pin. The PGOOD pin is an open-drain MOSFET which is pulled low when the FB pin voltage is less than 95% or greater than 105% of the reference voltage (VREF). The PGOOD pin floats (de-asserted) when the FB pin voltage is between 95% to 105% of VREF. The PGOOD pin is held low during startup or when a fault occurs.

The EN pin is used to provide power supply sequencing during power up. Soft start times for each frequency can be selected through the SS/FSEL pin. Soft start helps to minimize inrush currents.

The device current limit can be set via the ILIM pin. Two selectable current limits are provided.

The control scheme implemented is an adaptive on-time control. The on-time is adjusted based on input voltage and oscillator frequency. An internal phase lock loop (PLL) ensures fixed-frequency operation of the converter over the entire load range and adapts the on-time accordingly.

7.2 Functional Block Diagram

7.3 Feature Description

7.3.1 Frequency Selection

The oscillator frequency of this converter can be selected to be one of three options: 4, 7, or 10 MHz. The per phase switching frequency of the converter is half the oscillator frequency (that is, 2, 3.5, or 5 MHz per phase). The internal oscillator frequency is selected by programming the SS/FSEL pin. The resistor programming information is shown in Table 1. The frequency setting is latched in at power up and cannot be changed during operation. Cycling the input power or the EN pin will reset the frequency setting.

7.3.2 External Clock Syncronization

An external clock can be connected to the SYNC pin. The external clock signal overrides the internal oscillator and is used as the system clock. This feature enables the user to synchronize the switching events to a master clock on their board and reduce/manage the ripple on the input capacitors. The internal phase locked loop (PLL) has been implemented to allow synchronization at frequencies between ±10% of the nominal oscillator frequency programmed on the SS/FSEL pin. This allows the user to easily switch from the internal oscillator mode to the external clock mode. Before the external clock is present or after it is removed, the device with default to the internal oscillator setting as programmed on the SS/FSEL pin.

To implement the synchronization feature, connect a square wave clock signal to the SYNC pin with a duty cycle between 20% and 80%. The clock signal amplitude must transition lower than 0.8 V and higher than 2 V. The start of the switching cycle is synchronized to the rising edge of the SYNC pin. The device can be configured for operation in applications where both an internal oscillator mode and an external synchronization clock mode are needed. Before the external clock is present, the device functions with the internal oscillator and the switching frequency is set by the RSS/FSEL resistor. When the external clock is present, the SYNC mode overrides the internal oscillator. The first time the SYNC pin is pulled above the SYNC high threshold (2 V), the device switches from the internal oscillator mode to the SYNC mode and the PLL starts to lock onto the frequency of the external clock. When the external SYNC clock is removed, the converter will transition back to the internal oscillator after 4 internal clock cycles.

7.3.3 Adjusting the Output Voltage

The output voltage is set by connecting a resistor divider network from the output voltage to the FB pin of the device and to AGND. It is recommended that the lower divider resistor maintain a range between 1 kΩ and 10 kΩ. To change the output voltage of a design, it is necessary to select the value of the upper resistor. Equation 2 can be used to select the upper resistor. Selecting the value of the upper resistor can change the output voltage between 0.508 V and 2 V. The minimum output setpoint voltage cannot be less than the reference voltage of 0.508 V. The maximum output voltage can be limited by minimum input voltage as shown in Figure 24. The recommended minimum input voltage should be at least five times the output voltage as shown in Figure 25. This is due to the nature of the series capacitor buck converter.

7.3.4 Soft Start

Soft start is an important feature that limits current inrush into the converter and reduces the load on the bus converter that supplies this device. During soft start, the internal reference voltage is slowly ramped up to the nominal internal reference voltage (~0.5 V). This slowly increases the commanded output voltage of the converter and reduces the initial surge in current. PGOOD remains low during soft start, the PLL is not active, and output UVP/OVP faults are disabled. After the soft start interval is complete, the converter operates with normal operating conditions and PGOOD will no longer be held low when the output is within bounds.

Soft-start time is programmed with an external resistor on SS/FSEL pin (or by shorting to ground or by leaving the pin open). There are multiple soft-start time options per operating frequency available to the user through the SS/FSEL pin. The soft-start setting is latched in at power up or when the EN pin voltage is set high. Resistors used for programing the SS/FSEL pin must have ±1% or lower tolerance. The following frequencies and soft start times can be programmed on the SS/FSEL pin.

Table 1. Frequency and Soft Start Resistor Selection

| RSS/FSEL (kΩ) | FOSC (MHz) | FSW (MHz) | Soft Start Time (µs) | Hiccup Time (ms) |

|---|---|---|---|---|

| 71.5 | 4 | 2 | 64 | 32.8 |

| Open | 4 | 2 | 512 | 32.8 |

| 48.7 | 4 | 2 | 4096 | 32.8 |

| 35.7 | 7 | 3.5 | 36.6 | 18.7 |

| Short | 7 | 3.5 | 293 | 18.7 |

| 21.5 | 10 | 5 | 25.6 | 13.1 |

| 15.4 | 10 | 5 | 205 | 13.1 |

| 8.66 | 10 | 5 | 1638 | 13.1 |

7.3.5 Startup into Pre-biased Outputs

The device prevents the low-side MOSFETs from discharging a pre-biased output. During pre-biased startup, the low-side MOSFETs do not turn on until after the phase A high-side MOSFET has started switching. The high-side MOSFETs do not start switching until the internal soft-start reference voltage exceeds the voltage at the FB pin. It is required to first apply the gate driver supply voltage (VG+) before starting up into pre-biased loads. Alternatively, 6.8 µF bypass capacitance or more can be used.

7.3.6 Power Good (PGOOD)

The Power Good (PGOOD) pin is an open drain output. After startup when the FB pin is typically between 95% and 105% of the internal voltage reference, the PGOOD pin pull-down is de-asserted and the pin floats. It is recommended to use a pullup resistor between the values of 10 kΩ and 100 kΩ to a voltage source that is 5.5 V or less. The PGOOD is in a defined state once the VIN input voltage is greater than approximately 1.2 V but with reduced current sinking capability. The PGOOD achieves full current sinking capability once the VIN input voltage is above the input UVLO. The PGOOD pin is pulled low when the FB pin voltage is typically lower than 95% or greater than 105% of the nominal internal reference voltage. A resistor-capacitor (RC) filter can be connected to the PGOOD pin to filter out PGOOD being pulled low during large load transients if low output capacitance is used. The PGOOD pin is also pulled low if a fault is detected, the EN pin is pulled low, or the converter is performing its soft-start power up sequence.

7.3.7 Overcurrent Protection

The device protects itself from an overcurrent condition by a current limit detector. The device senses inductor currents using the low side MOSFETs. After three sequential overcurrent measurements are made (in phase A or B), the over current flag is triggered, the converter switches are turned off, and PGOOD is pulled low. The converter attempts to restart after a hiccup interval counter has expired (that is, 32.8 ms, 18.7 ms, or 13.1 ms when in 4 MHz, 7 MHz, or 10 MHz mode, respectively). This provides a hiccup response to an overcurrent condition.

The two overcurrent trip points are based on two full load applications of 7.5 A or 10 A. The overcurrent trip points correspond to the load demanding 1.5 times the full load current (11.25 A and 15 A, respectively). This provides enough margin for brief overshoots in inductor currents during a load transient while at the same time protecting against short circuits or other potentially catastrophic faults on the output. The table below lists the resistor values for programming the ILIM pin to select the desired overcurrent limit. Programming resistors with up to ±5% variation can be used. The current limit selection is latched in at power up and cannot be changed without cycling power input or the EN pin voltage.

Table 2. Current Limit Selection

| RILIM (kΩ) | Load Current Limit (A) |

|---|---|

| Open | 15 |

| 47 | 11.25 |

7.3.8 Light Load Operation

The converter operates in forced continuous conduction mode (FCCM) under light load conditions. When operating in FCCM, the high side and low side MOSFETs are turned on and off in a complementary fashion and negative inductor current is allowed for part of the switching cycle. The switching frequency remains constant in FCCM.

7.3.9 Output Undervoltage/Overvoltage Protection

The device incorporates an output undervoltage/overvoltage protection (UVP/OVP) circuit to prevent damage to the load. This fault can be triggered during large, fast load transients if insufficient output capacitance is used. The UVP/OVP feature compares the FB pin voltage to internal thresholds. If the FB pin voltage is lower than 90% or greater than 110% of the nominal internal reference voltage, the converter is turned off (i.e. power MOSFETs are turned OFF), a fault is triggered, and the PGOOD pin is pulled low. When the fault hiccup interval is complete, the converter will attempt to restart.

7.3.10 Input Undervoltage/Overvoltage Lockout

The device incorporates an input undervoltage/overvoltage lockout (UVLO/OVLO) circuit. The converter will not operate if the input voltage is below the UVLO threshold. The OVLO circuit protects the converter if the input bus voltage flies higher than the input voltage rating of the device while it is switching. When the input voltage crosses the input rising OVLO trip threshold, the converter turns off all the switches (makes them high impedance) and PGOOD is pulled low. When the input voltage drops lower than the falling OVLO threshold, the converter restarts using the normal soft-start sequence. This feature increases the maximum input voltage the device can sustain without being damaged due to a fault in the system.

7.3.11 Enable and Adjusting Undervoltage Lockout

The EN pin provides electrical on and off control of the device. Once the EN pin voltage exceeds the threshold voltage, the device starts operation. If the EN pin voltage is pulled below the threshold voltage, the regulator stops switching and enters a low power state. There is no voltage hysteresis in the EN threshold. The rising and falling voltage thresholds occur at the same level.

The EN pin has an internal hysteretic current source. This allows the user to float the EN pin for self-enabling the device or to design the ON and OFF threshold input voltages with a resistor divider at the EN pin. If an application requires controlling the EN pin, use open drain or open collector output logic to interface with the pin.

The EN pin can be configured as shown in Figure 42. The EN pin has a 1 µA pull-up current iP which sets the current source value before the start-up sequence. The device includes the second 3 µA current source iH which is activated when the EN threshold voltage has been exceeded. To achieve clean transitions between the OFF and ON states, it is recommended that the turn OFF threshold is no less than 7.75 V, and the turn ON threshold is no less than 8 V on the VIN pin. It is also recommended to set the UVLO hysteresis to be greater than 500mV in order to avoid repeated chatter during start up or shut down. The value of REN(TOP) and REN(BOT) can be calculated using Equation 18 and Equation 19 as described in the applications section.

Figure 42. Adjustable VIN Undervoltage Lockout

Figure 42. Adjustable VIN Undervoltage Lockout

7.3.12 Series Capacitor Monitoring

The series capacitor voltage is preconditioned and monitored during operation. The series capacitor is located between the source of the high-side MOSFET and the drain of the low-side MOSFET in Phase A . After the input voltage is above UVLO and the EN pin is high, the series capacitor is precharged. A 10 mA current source charges the series capacitor up to half the input voltage. When the series capacitor precharge is complete, the soft start sequence begins. The delay due series capacitor precharge can be calculated using Equation 1.

Here Ct is the series capacitance, Ipc is the precharge current, and VIN is the input voltage.

The voltage monitor is continuously tracking the status of the series capacitor. Its function is to ensure the series capacitor voltage, measured differentially between the SCAP pin and the SWA pin, stays within predefined thresholds. These thresholds are relative to the VIN voltage with respect to PGND and set at 35% and 65% of VIN. If the voltage monitor indicates a voltage outside of these thresholds has occurred, a fault is triggered and following actions are taken based on which threshold has been crossed.

7.3.12.1 Dropping Below 35% Threshold

The 35% of VIN threshold detects a series capacitor undervoltage fault. Once the 35% threshold is breached, a fault is triggered, the converter shuts down, and PGOOD is pulled low. After the fault hiccup time is complete, the converter will start up in the normal manner. The start up sequence begins with pre-charging the series capacitor to half the input voltage and is followed by the soft start.

7.3.12.2 Rising Above 65% Threshold

The 65% of VIN threshold indicates a series capacitor overvoltage fault has occurred. Once the 65% threshold is breached, a fault is triggered, the converter shuts down, PGOOD is pulled low, and an internal bleed resistor is connected to the SCAP to reduce the series capacitor voltage. After the fault hiccup time is complete, the converter will start up in the normal manner.

7.3.13 Thermal Shutdown

The die temperature is continuously monitored to ensure it is within limits. The thermal shutdown (TSD) fault is triggered when the die temperature exceeds the rising temperature threshold. This interrupts switching by making the switches high impedance. The fault state persists until the die temperature cools down to below the falling temperature threshold. The converter then automatically goes through the normal soft start sequence.

7.3.14 Phase A Power Stage

Phase A implements a bootstrap driver for the high-side MOSFET, an LDO, a low-side driver and a low-side current monitor. Additional logic is included to implement deadtime control and overcurrent protection.

An LDO is implemented to manage the high-side bootstrap driver. This LDO is unique to this topology given the high-side driver is referenced to the SCAP pin and not to the conventional switch node of a buck converter. A conventional bootstrap circuit will not work because the SCAP pin is never connected to PGND during operation. The LDO is designed to produce an output voltage at the VGA pin. This allows a nominal enhancement of around 5V about the VIN rail. The bootstrap capacitor charges when the phase A low side switch is on. An external decoupling capacitor is required on the VGA pin.

The low-side MOSFET current is monitored using a sense FET configuration. This circuit enables the driver to monitor the current delivered in Phase A for overcurrent protection. In the case of overcurrent, a fault flag is set if the current detected exceeds the current limit threshold. Adjustment of this threshold is accomplished via programming the ILIM pin.

7.3.15 Phase B Power Stage

Phase B implements a bootstrap driver for the high-side MOSFET, a low-side driver and a low-side current monitor. Additional logic is included to implement deadtime control and overcurrent protection.

No additional LDO function is required for Phase B as the bootstrap capacitor is charged directly from the VG input rail. A conventional bootstrap circuit is used in phase B.

The overcurrent protection operates in the same manner as Phase A.

7.3.16 Internal Gate Drive Regulator

There is an internal linear regulator that generates a 4.8 V supply rail on the VG+ pin. The input comes from the VIN pin. The VG+ supply rail is used to power the gate drivers of phase A low side switch and phase B switches. It also is the input to another regulator that generates the internal supply rails used by the controller. To improve converter efficiency, an external 5V supply is recommended to be connected to the VG+ pin, thereby overriding the internal 4.8 V regulator. The VG+ supply requires external decoupling capacitance connected between the VG+ and VG- pins. The VG- pin must be connected to AGND and PGND. It is recommended to make this connection directly beneath the device.

7.3.17 Voltage Feed Forward

The input voltage feed forward (VFF) circuit adapts the nominal on-time of the converter in response to changes in the input voltage. The VFF provides a control signal to the on-time generator based on the value of the resistor placed on the TON pin and the input voltage.

7.3.18 Internal Oscillator

The internal oscillator provides a default system clock for the converter. The oscillator can be programmed to run at 4 MHz, 7 MHz, or 10 MHz depending on the resistor connected to the SS/FSEL pin. Synchronization to an external clock is allowed. If provided, an external synchronization clock signal is passed through to the oscillator block and bypasses internal oscillator.

7.3.19 Pulse Frequency Detector

The pulse frequency detector is an important block used to create a phase lock loop (PLL). This portion of the PLL accepts two clock signals and delivers a control signal. The PLL control is held inactive during startup and is activated once soft start is complete. The control signal is delivered to the on-time generator to make small adjustments in the on-time such that the frequency and phase of the switching signals match the reference clock (internal or external SYNC).

7.3.20 On-Time Generator

The on-time generator provides the on-time pulse for high side switches of the converter. The nominal on-time is programmed from the TON pin. The control signal generated by the VFF circuit is proportional to the on-time required by the converter and is adjusted for input voltage variation. Fine adjustment of the on-time comes from pulse frequency detector which enables fixed frequency operation in steady state.

8 Application and Implementation

NOTE

Information in the following applications sections is not part of the TI component specification, and TI does not warrant its accuracy or completeness. TI’s customers are responsible for determining suitability of components for their purposes. Customers should validate and test their design implementation to confirm system functionality.

8.1 Application Information

The TPS54A20 is a two-phase, synchronous series capacitor buck converter optimized for small size, low voltage applications from a 12 V input rail. See (SLVA750) for a more detailed introduction to the series capacitor buck converter topology.

8.1.1 Two-Phase Series Capacitor Buck Converter Topology

The series capacitor buck converter topology uniquely merges a switched capacitor converter and a buck converter. Only one extra capacitor (the series capacitor) is needed as compared to a conventional two-phase buck converter. Advantages include automatic current balancing between the inductors (inductor current sensing and a current sharing loop are not required), lower switching losses which enable high frequency (HF) operation, and voltage step-down through the series capacitor. The on-time of both high side switches is double that of a regular buck converter. This is particularly helpful in high frequency, high conversion ratio applications. The schematic of the converter topology and the converter switch states are shown below.

Figure 43. Two-Phase Series Capacitor Buck Converter Topology

Figure 43. Two-Phase Series Capacitor Buck Converter Topology

8.1.2 Converter Switch Configurations

Figure 44. Phase A High Side MOSFET On

Figure 44. Phase A High Side MOSFET On

Figure 46. Phase A/B Low Side MOSFET On

Figure 46. Phase A/B Low Side MOSFET On

Figure 45. Phase B High Side MOSFET On

Figure 45. Phase B High Side MOSFET On

8.2 Typical Application

Figure 47. Typical Application

Figure 47. Typical Application

8.2.1 Design Requirements

Table 3. Design Parameters

| PARAMETER | CONDITIONS | MIN | TYP | MAX | UNIT | |

|---|---|---|---|---|---|---|

| VOUT | Output voltage | 1.2 | V | |||

| IOUT | Output current | 10 | A | |||

| ΔVOUT | Transient response | 9-A load step | 60 | mV | ||

| VIN | Input voltage | 9.2 | 12 | 14 | V | |

| VOUT(ripple) | Output voltage ripple | 20 | mV(P-P) | |||

| Start input voltage | Input voltage rising | 9.4 | V | |||

| Stop input voltage | Input voltage falling | 9.2 | V | |||

| fSW | Switching frequency | 2 | MHz | |||

| TA | Ambient temperature | 25 | °C | |||

8.2.2 Detailed Design Procedure

8.2.2.1 Output Voltage

Before beginning design, ensure that the series capacitor buck converter can be used in the application. It is recommended to use this converter when the minimum input voltage is at least five times greater than the target output voltage. If this recommendation is not followed, output voltage dropout can occur at heavy load conditions and poor transient response to load increases can result.

The output voltage is set by connecting a resistor divider network from the output voltage to the FB pin of the device and to AGND. It is recommended that the lower divider resistor maintain a range between 1 kΩ and 10 kΩ. To change the output voltage of a design, it is necessary to select the value of the upper resistor. The value of RTOP for a specific output voltage can be calculated using Equation 2.

For the example design, 1 kΩ was selected for RBOT (R7). Using Equation 2, RTOP (R9) is calculated as 1.4 kΩ. It is recommended to use resistors with ±1% or less variation.

A capacitor can be connected in parallel with the upper resistor to provide additional phase boost near the converter's crossover frequency. See (SLVA289) for more details and design guidelines. For this design, 330 pF in series with 100 Ω is used. The values were optimized based on measured loop performance.

8.2.2.2 Switching Frequency

A key design step is to decide on a switching frequency for the regulator. There is a tradeoff between higher and lower switching frequencies. Higher switching frequencies may produce a smaller solution size using lower valued inductors and smaller output capacitors compared to a power supply that switches at a lower frequency. However, the higher switching frequency creates extra switching loss, which reduces the converter’s efficiency and thermal performance. In this design, a moderate switching frequency of 2 MHz per phase is selected to achieve both a small solution size and a high efficiency operation. Refer to Table 1 for the SS/FSEL programming resistor selection.

8.2.2.3 On-Time

The TON pin requires a resistor to set the nominal on-time and to support the input voltage feedforward circuit. The resistance value used also influences the internal ramp in the controller. As a starting point, Equation 3 is recommended for selecting the TON resistor.

The RTON resistor (R5) is calculated to be 21 kΩ. The selected value for this design example is 22.1 kΩ. During startup, the converter uses the nominal on-time programmed through TON. The phase lock loop (PLL) is only activated after startup is complete. When the PLL is engaged, the on-time is adjusted. If the nominal on-time programmed through the TON pin is not close to the on-time when the PLL is engaged, the SYNC range of the device may be reduced. The TON resistor can also be adjusted to tune the controller. Lowering the RTON value will increase the internal ramp height. This will reduce the converter’s sensitivity to noise and jitter but it will also reduce the transient response capabilities of the converter.

8.2.2.4 Inductor Selection

To calculate the value of the output inductors, use Equation 4. KIND is a coefficient that represents the amount of inductor ripple current relative to the maximum output current. The inductor ripple current is filtered by the output capacitor. In general, the inductor ripple value is at the discretion of the designer; however, KIND is normally from 0.1 to 0.4 for the majority of applications.

For this design example, use KIND = 0.4 and the inductor value is calculated to be 249 nH. For this design, the nearby standard value of 220 nH was chosen. For the output filter inductor, it is generally recommended that the RMS current and saturation current ratings not be exceeded. The current ripple, RMS, and peak inductor current are calculated in Equation 5, Equation 6, and Equation 7.

For this design, the RMS inductor current is calculated to be 5.04 A and the peak inductor current is 6.13 A. The chosen inductor is 220 nH with a saturation current rating of 8.2 A and a dc current rating of 7.6 A.

The current flowing through each inductor is the inductor ripple current plus half the output current. During power up, faults, or transient load conditions, the inductor current can increase above the peak inductor current level calculated above. In transient conditions, the inductor current can increase up to the switch current limit of the device. For this reason, the most conservative approach is to specify an inductor with a saturation current rating equal to or greater than half the load current limit rather than the peak inductor current in steady state. Many inductors today have soft saturation characteristics that may be able to ride through a transient that pushes current beyond the saturation rating specified in the datasheet. An example list of inductors that have been tested to work with the TPS54A20 are shown in Table 4. Inductors not listed below can also be used with this device.

Table 4. Example Inductor List

| Inductance (nH) | Saturation Current Rating (A) | Dimensions [L x W x H] (mm) |

DCR Typ/Max (mΩ) | Type | Vendor |

|---|---|---|---|---|---|

| 220 ±20% | 9.3 | 3.2 x 2.5 x 1.2 | 9 / 12 | HMLW32251B-R22MS | CYNTEC |

| 330 ±20% | 7.5 | 3.2 x 2.5 x 1.2 | 13 / 16 | HMLW32251B-R33MS | CYNTEC |

| 220 ±30% | 8.2 | 3.2 x 2.5 x 1.2 | 7.5 / 10.5 | MLA-FY12NR22N-M3 | MAGLAYERS |

| 330 ±30% | 7.5 | 3.2 x 2.5 x 1.2 | 13.5 / 16 | MLA-FY12NR33N-M3 | MAGLAYERS |

| 220 ±20% | 8.7 | 3.2 x 2.5 x 1.2 | 9.4 / 11.6 | MCMK3225TR22MG | TAIYO YUDEN |

| 330 ±20% | 10.4 | 3.2 x 2.5 x 1.2 | 11.2 / 13.8 | MCMK3225TR33MG | TAIYO YUDEN |

| 250 ±30% | 12 | 3.2 x 2.5 x 1.5 | 10 / 12.5 | 74479290125 | WURTH ELECTRONIK |

| 330 ±30% | 12.4 | 4.1 x 4.1 x 2.1 | 6 / 7.2 | 744383560033 | WURTH ELECTRONIK |

| 220 ±20% | 10.1 | 3.5 x 3.2 x 1.5 | 7.8 / 8.9 | XEL3515-221 | COILCRAFT |

| 350 ±20% | 8.2 | 3.5 x 3.2 x 1.5 | 11.6 / 13.4 | XEL3515-351 | COILCRAFT |

| 330 ±20% | 8.5 | 2.5 x 2.0 x 1.2 | 14 / 19 | DFE252012F-R33M | TOKO |

8.2.2.5 Output Capacitor Selection

For most applications, the primary consideration for selecting the value of the output capacitor is how the regulator responds to a large change in load current. The output capacitance may also be selected based on output voltage ripple or closed-loop bandwidth design objectives.

The output capacitance required to maintain an output voltage ripple ΔVOUT during steady-state operation can be estimated using Equation 8.

The desired response to a large change in the load current is typically the most stringent criteria. The output capacitor needs to supply the load with current when the regulator cannot. This situation would occur if there are desired hold-up times for the regulator where the output capacitor must hold the output voltage above a certain level for a specified amount of time after the input power is removed. The regulator is also temporarily not able to supply sufficient output current if there is a large, fast change in the load current such as a transition from no load to full load. The output capacitor must be sized to supply the extra current to the load until the control loop responds to the load change. The minimum output capacitance required for a load increase can be estimated using Equation 9.

In low voltage applications, the inductor slew rate during a load step decrease is sometimes slower than its slew rate during a load step increase. The minimum output capacitance required for a load decrease can be estimated using Equation 10 for a given tolerable amount of overshoot in the output voltage.

Here ΔIOUT is the change in output current and ΔVOUT is the allowable change in the output voltage. For this design example, the transient load response is specified as a 3% change in VOUT for a load step of 5A. For this example, ΔIOUT = 5 A and ΔVOUT = 0.03 x 1.2 = 0.036 V. Based on these design parameters, a minimum capacitance of 93 µF is calculated using Equation 9. This value does not take the ESR of the output capacitor into account in the output voltage change. For ceramic capacitors, the ESR is usually small enough to ignore in this calculation. Additional capacitance de-ratings for aging, temperature and DC bias should be factored in which also increases this minimum value. For this design example, two 47 µF, 6.3 V rated, ceramic capacitors with 3 mΩ of ESR are selected.

8.2.2.6 Input Capacitor Selection

The TPS54A20 requires a high quality ceramic, type X5R or X7R, input decoupling capacitor of at least 4.7 µF of effective capacitance on the VIN input voltage pin. Additional bulk capacitance may also be required for the VIN input. The value of a ceramic capacitor varies significantly over temperature and the amount of DC bias applied to the capacitor. The capacitance variations due to temperature can be minimized by selecting a dielectric material that is stable over temperature. X5R and X7R ceramic dielectrics are usually selected for power regulator capacitors because they have a high capacitance to volume ratio and are fairly stable over temperature. The capacitor must also be selected with the DC bias taken into account. The capacitance value of a capacitor decreases as the DC bias across a capacitor increases. For this example design, a ceramic capacitor with at least a 25-V voltage rating is selected to support the maximum input voltage. The input capacitance value impacts the input ripple voltage of the regulator. The minimum input capacitance can be estimated using Equation 11.

Here ΔVIN is the input voltage ripple in steady state. Using the design example values, IOUT = 10 A, VOUT = 1.2 V, VIN(MIN) = 9 V, FSW = 2 MHz and ΔVIN = 25 mV, Equation 11 yields an input capacitance of 39 µF. For this example, two 10µF, 25-V and a single 22-µF, 25-V ceramic capacitors in parallel have been selected for the VIN voltage rail. Because ESR is typically fairly low in ceramic capacitors, it is not included in this calculation.

The capacitor must also have a ripple current rating greater than the maximum input current ripple to the device during full load. The input ripple current can be calculated using Equation 12.

For this example design, the RMS input ripple current is 2.21 A (RMS). The ripple current can be assumed to be shared equally between the input capacitors.

8.2.2.7 Series Capacitor Selection

A major function of the series capacitor is energy transfer. This is a different role from input and output capacitors where decoupling is the primary function. In many ways, the series capacitor is similar to the capacitor used for energy transfer in SEPIC converters and can be designed accordingly. A design objective may be to ensure the series capacitor voltage ripple does not exceed 5% to 10% of the nominal voltage under the worst case conditions. The series capacitor voltage ripple is given by Equation 13.

Here Ct is the series capacitance. Equation 13 can be rearranged to provide the design equation for series capacitor selection which is

where kCt represents the voltage ripple percentage. For example, if the voltage ripple target is 5%, the value for kCt is 0.05. The largest voltage ripple occurs at full load current (highest IOUT), highest duty ratio (lowest input voltage/highest output voltage), and lowest frequency. For this design example, the value for kCt was selected to be 0.08. The resulting series capacitance calculated is 1.85 µF. A 10 V, X7R ceramic capacitor with 2.2 µF of capacitance is selected.

Another aspect to consider is capacitor RMS current rating. This impacts the temperature rise of the capacitor. Check the capacitor datasheet for temperature rise information. If the temperature rise is too large for a single capacitor, multiple capacitors may be placed in parallel to share the RMS current. The series capacitor has the same current profile as the high side MOSFETs. The RMS current squared can be expressed as

where IL(RMS) is the RMS inductor current of either inductor. The series capacitor RMS current can be expressed as

where ΔIL is the inductor current ripple. The largest RMS current occurs at the highest load current and highest duty ratio.

Multilayer ceramic capacitors (MLCC) are well suited for operating as the series capacitor. The equivalent series resistance (ESR) is relatively low (for example, 5 mΩ to 10 mΩ) which helps to reduce power loss and self heating. The equivalent series inductance (ESL) is fairly low which results in a high self resonant frequency (SRF). There are a few key items that should be considered when designing. First, the effective capacitance decreases with DC bias. This means that the capacitor should be selected based on its capacitance with the nominal voltage of VIN/2 applied. Temperature variation also reduces effective capacitance. For this reason, X7R capacitors with up to 125°C operating temperature range are recommended. If capacitors are not properly selected, cracking or other failure modes may result.

8.2.2.8 Soft-Start Time Selection

The soft-start time is the amount of time it takes for the output voltage to reach its nominal programmed value during power up. This is useful if a load requires a controlled voltage slew rate. This is also used if the output capacitance is very large and would require large amounts of current to quickly charge the capacitor to the desired output voltage level. The large currents necessary to charge the capacitor may make the TPS54A20 reach the current limit and trigger a fault. Excessive current draw from the input power supply may cause the input voltage rail to sag. Limiting the output voltage slew rate solves both of these problems. The soft-start time can be selected using the resistor values listed in Table 1. For the example circuit, the soft-start time is not critical since the output capacitor value is 94 µF which does not require a large amount of current to charge to 1.2 V. For this example design, the average output current is approximately 220 mA during soft start. The example circuit has the soft start time set to 512 µs which requires no resistor (open connection) on the SS/FSEL pin. The average converter output current required to charge the output capacitors to the target output voltage during soft start can be estimated using Equation 17.

8.2.2.9 Bootstrap Capacitor Selection

A 0.047 μF ceramic capacitor should be connected between the BOOTA to SCAP pins and between the BOOTB and SWB pins for proper operation. It is recommended to use a ceramic capacitor with X5R or better grade dielectric. The capacitor should have 10 V or higher voltage rating.

8.2.2.10 Gate Drive Capacitor Selection

A 1 μF ceramic capacitor should be connected between VGA and PGND and between the VG+ and VG- pins for proper operation. It is recommended to use a ceramic capacitor with X5R or better grade dielectric. The VGA capacitor should have 16 V or higher voltage rating and the VG+ capacitor should have 10 V or higher voltage rating.

8.2.2.11 Under Voltage Lockout Set Point

The Under Voltage Lock Out (UVLO) set point can be adjusted using an external voltage divider network. The top resistor is connected between VIN and the EN pin and bottom resistor is connected between EN and GND as shown in Figure 42. For the example design, the supply should turn on and start switching once the input voltage increases above 9.4 V (UVLO start or enable). After the regulator starts switching, it should continue to do so until the input voltage falls below 9.2 V (UVLO stop or disable). The resistor values for obtaining the desired UVLO thresholds can be calculated using Equation 18 and Equation 19. REN,TOP, the top UVLO divider resistor, is calculated using Equation 18. REN,BOT, the bottom UVLO divider resistor, is calculated in Equation 19.

For the start and stop voltages specified the resistor value selected for REN,TOP (R2) is 80.6 kΩ and for REN,BOT (R3) is 12.4 kΩ.

8.2.2.12 Current Limit Selection

The current limit can be selected using the ILIM pin. Refer to Table 2 for resistor selection information. It is recommended to choose a current limit that is 1.5 times or more than the full load current expected in the application. This allows for margin in the inductor currents when responding to load transients and limits nuisance trips.

8.2.3 Application Curves

Figure 48. Efficiency

Figure 48. Efficiency

Figure 50. Load Regulation

Figure 50. Load Regulation

Figure 52. Loop Response

Figure 52. Loop Response

Figure 54. No Load Input Voltage Ripple

Figure 54. No Load Input Voltage Ripple

Figure 56. No Load Output Voltage Ripple

Figure 56. No Load Output Voltage Ripple

Figure 58. Start Up with VIN

Figure 58. Start Up with VIN

Figure 60. Shut Down with VIN

Figure 60. Shut Down with VIN

Figure 49. Light Load Efficiency

Figure 49. Light Load Efficiency

Figure 51. Line Regulation

Figure 51. Line Regulation

Figure 53. Transient Response

Figure 53. Transient Response

Figure 55. Full Load Input Voltage Ripple

Figure 55. Full Load Input Voltage Ripple

Figure 57. Full Load Output Voltage Ripple

Figure 57. Full Load Output Voltage Ripple

Figure 59. Start Up with EN

Figure 59. Start Up with EN

Figure 61. Shut Down with EN

Figure 61. Shut Down with EN