JAJSKM1C october 2019 – september 2021 UCC5870-Q1

PRODUCTION DATA

- 1

- 1 特長

- 2 アプリケーション

- 3 概要

- 4 Revision History

- 5 Pin Configuration and Functions

- 6 Specifications

-

7 Detailed Description

- 7.1 Overview

- 7.2 Functional Block Diagram

- 7.3

Feature Description

- 7.3.1 Power Supplies

- 7.3.2 Driver Stage

- 7.3.3 Integrated ADC for Front-End Analog (FEA) Signal Processing

- 7.3.4 Fault and Warning Classification

- 7.3.5

Diagnostic Features

- 7.3.5.1 Undervoltage Lockout (UVLO) and Overvoltage Lockout (OVLO)

- 7.3.5.2 CLAMP, OUTH, and OUTL Clamping Circuits

- 7.3.5.3 Active Miller Clamp

- 7.3.5.4 DESAT based Short Circuit Protection (DESAT)

- 7.3.5.5 Shunt Resistor based Overcurrent Protection (OCP) and Short Circuit Protection (SCP)

- 7.3.5.6 Temperature Monitoring and Protection for the Power Transistors

- 7.3.5.7 Active High Voltage Clamping (VCECLP)

- 7.3.5.8 Two-Level Turn-Off

- 7.3.5.9 Soft Turn-Off (STO)

- 7.3.5.10 Thermal Shutdown (TSD) and Temperature Warning (TWN) of Driver IC

- 7.3.5.11 Active Short Circuit Support (ASC)

- 7.3.5.12 Shoot-Through Protection (STP)

- 7.3.5.13 Gate Voltage Monitoring and Status Feedback

- 7.3.5.14 VGTH Monitor

- 7.3.5.15 Cyclic Redundancy Check (CRC)

- 7.3.5.16 Configuration Data CRC

- 7.3.5.17 SPI Transfer Write/Read CRC

- 7.3.5.18 TRIM CRC Check

- 7.4 Device Functional Modes

- 7.5 Programming

- 7.6 Register Maps

- 8 Applications and Implementation

- 9 Power Supply Recommendations

- 10Layout

- 11Device and Documentation Support

- 12Mechanical, Packaging, and Orderable Information

7.3.5.17 SPI Transfer Write/Read CRC

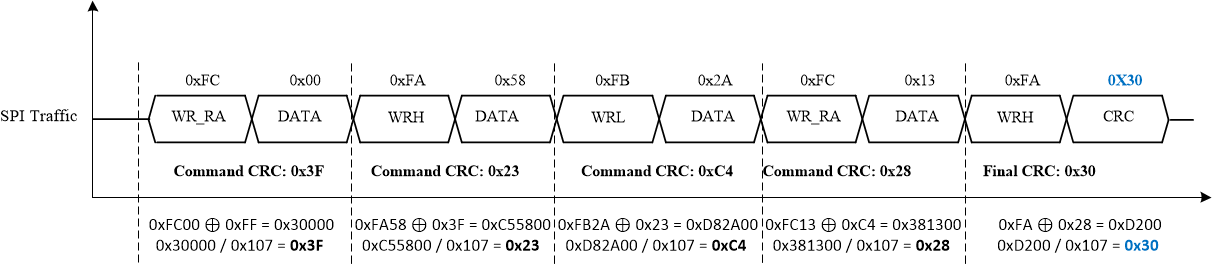

The CRC checks for SPI transfer are continuously updated as SPI traffic is received/ sent. The CRC is updated with every 16-bits that are received. An example of calculating the SPI CRC for a sent command is given in Figure 7-36. In this set of commands, we are updating the configuration for CFG1 and then doing a CRC comparison on that command.

Table 7-2 Example of CRC Calculation While Updating CFG1

| Command | Purpose | CRC Before | CRC_After |

|---|---|---|---|

| 0xFC00 | Change the SPI address pointer to CFG1 register | 0xFF (Initialized) | 0x3F |

| 0xFA58 | Update the high byte with 0x58 configuration | 0x3F | 0x23 |

| 0xFB2A | Update the low byte with 0x2A configuration | 0x23 | 0xC4 |

| 0xFC13 | Change the SPI address point to CRCDATA register | 0xC4 | 0x28 |

| 0xFA30 | Update the CRC_TX bits with the calculated CRC | 0x28 | 0x30 (written to the CRC_TX bits) |

Figure 7-36 Calculating CRC for a Set of Commands

Figure 7-36 Calculating CRC for a Set of Commands