SLAAEK6 June 2024 ULC1001 , ULC1001-Q1

3.4.2 Transducer

The transducer acts as the actuator in the application.

Material: The recommended transducer material is PZT. TI uses PZT 8 in the prototypes considering the high mechanical quality factor. Other PZT materials such as PZT4 or PZT5 can be options as well.

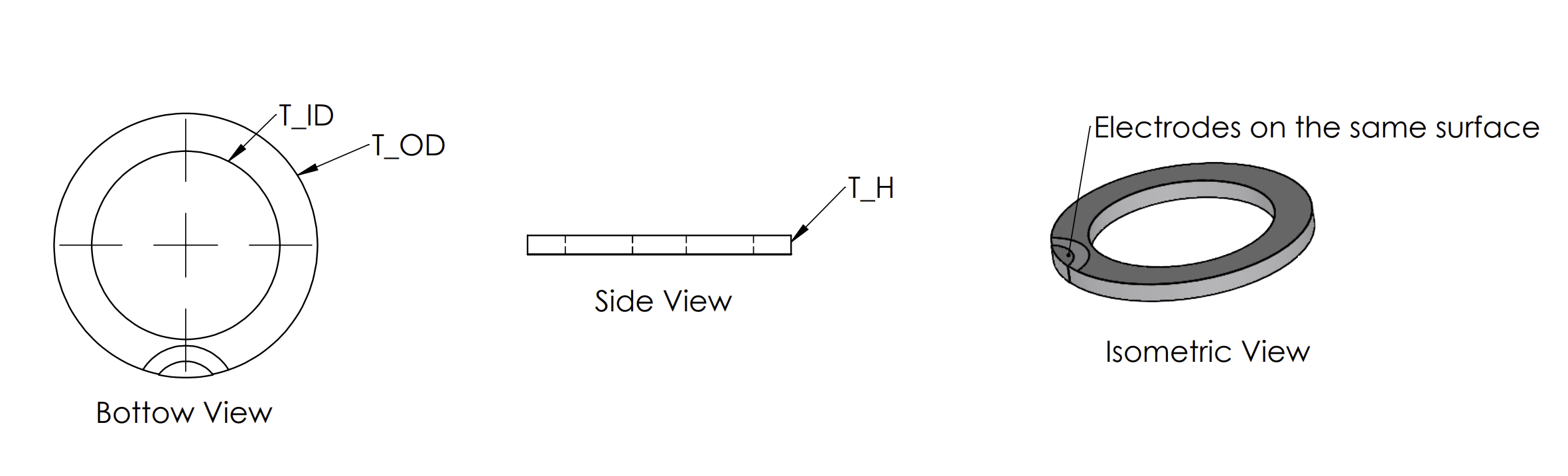

Geometry: The transducer is a ring shape and is poled in the top/bottom direction. Figure 3-6 shows the top view, side view and isometric view of the transducer and also illustrates the dimensions of the transducer. T_ID, T_OD, and T_H represent the inner diameter, outer diameter and the height of the transducer, respectively.

Figure 3-6 Transducer: Top View, Side View

and Isometric View

Figure 3-6 Transducer: Top View, Side View

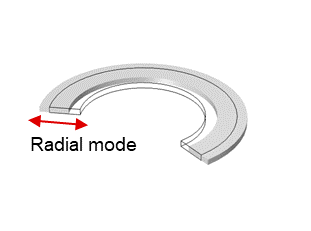

and Isometric ViewThere are multiple resonant modes of the ring piezo. In this application, the radial mode is utilized for the cleaning modes and the resonant frequency can be estimated by the following equation:

where is the density of the material, and is elastic compliance at constant electric field. This can be further simplified as

where C is a constant, whose value is estimated to be about 2000 for PZT 8 material. Piezo suppliers have slightly different C values for the same type of the piezo material due to their recipe variances.

Figure 3-7 Radial Mode of Piezo for Water

Cleaning

Figure 3-7 Radial Mode of Piezo for Water

Cleaning- The wall thickness ((T_OD-T_ID)/2) between the lens must be at least 3mm to maintain a large gluing area between the piezo and the lens.

- The wall thickness ((T_OD-T_ID)/2) is typically more than 2 times the piezo thickness to be a ring-shaped piezo (thin and wide).