SLAAEK6 June 2024 ULC1001 , ULC1001-Q1

3.3 Design Procedure

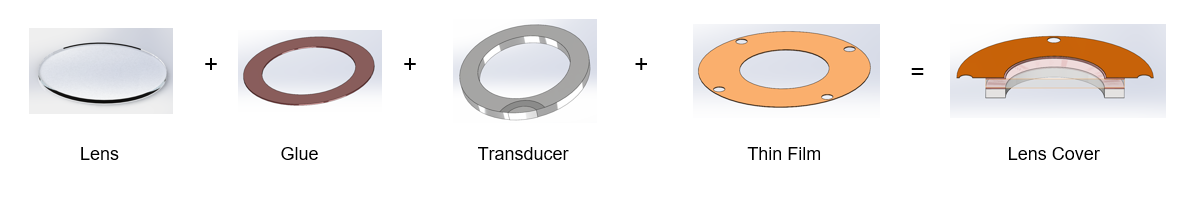

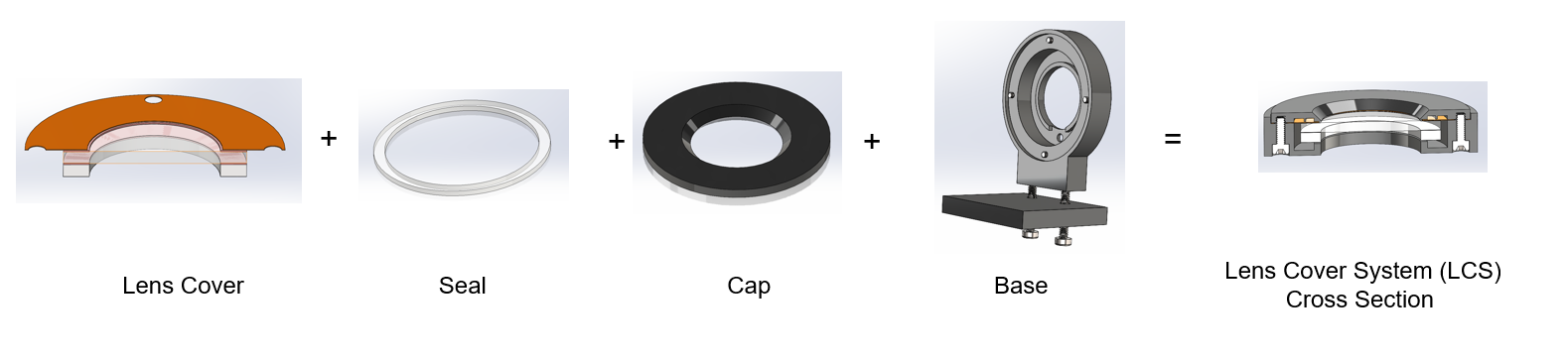

The mechanical design procedure involves designing each individual component and assembling the components to build the LCS. In particular, the design procedure (Figure 3-3 and Figure 3-4) can be described by the following steps :

- Determine the minimum cover lens aperture (that is, transducer inner diameter) based on the camera lens diameter.

- Design the lens and transducer that is well matched to achieve the best cleaning performance.

- Design a glue fixture that can help glue Lens Cover components easily.

- Assemble lens, transducer and thin film by following the proper gluing procedure to create a Lens Cover.

- Design housing cap and base based on the Lens Cover dimensions.

- Assemble the Lens Cover and housing to create a Lens Cover System (LCS).

Figure 3-3 Mechanical Design Procedure of Flat Lens LCS: Lens + Glue + Transducer + Thin Film = Lens Cover

Figure 3-3 Mechanical Design Procedure of Flat Lens LCS: Lens + Glue + Transducer + Thin Film = Lens Cover

Figure 3-4 Mechanical Design Procedure of Flat Lens LCS: Lens Cover + Cap + Seal + Base = Lens Cover System (LCS)

In LCS design, the most critical is to design a Lens Cover where the lens and the transducer is well matched. TI uses a FEA simulation tool- COMSOL Multiphysics to simulate the interactions between the components. Other FEA simulation tools such as Ansys can be used as well.

The goal of the simulation is to obtain the highest lens surface acceleration by sweeping the dimensional parameters of the lens and piezo transducer.