SLAAEK6 June 2024 ULC1001 , ULC1001-Q1

3.4.5.2 Flexible Seal

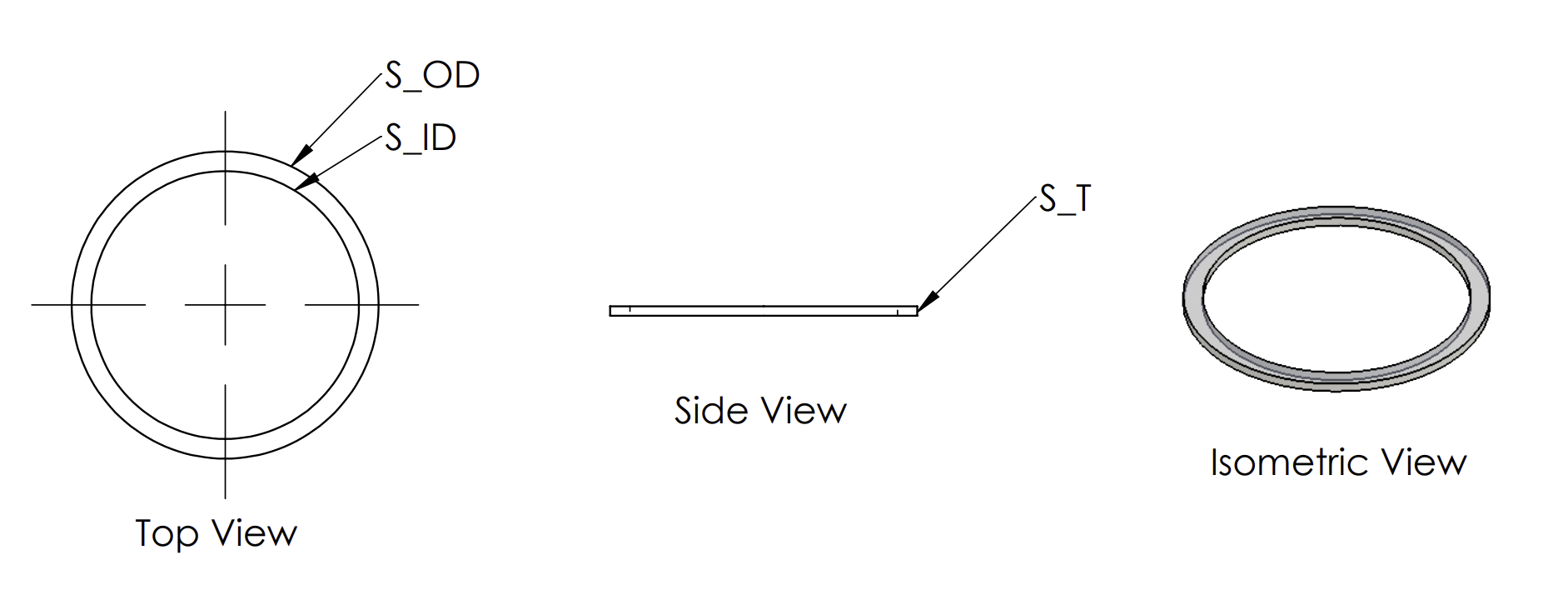

The seal between the cap and the thin film maintains a watertight proof as the lens cover vibrates to expel contaminants. Figure 3-11 illustrates the top view, side view, and isometric view of the seal for housing after hardening.

Material: The recommended seal material is silicone that is soft enough to induce minimal damping during ULC vibration and that can also avoid cracking over weather temperature cycles during the product life cycle. This exhibits excellent resistance to heat, compression set, boiling water, and has excellent low-temperature flexibility.

Figure 3-11 Seal: Top View, Side View and Isometric View after Hardening

Figure 3-11 Seal: Top View, Side View and Isometric View after Hardening