SLLA585 April 2022 THVD2410 , THVD2450

2.3 Slowing Fast Edges

In several applications, the data rate is not perfectly aligned with the recommended data rate of the device. For example, THVD2450 works at a maximum data rate of 50-Mbps, while THVD2410 works at a maximum data rate of 500-kbps defined by the data sheet. In applications, data rates may fall in between these two values, which raises a common question – can high-speed RS-485 devices be used in low-speed applications? In general, high-speed devices have fast edges (short rise/fall time). These sharp edges may generate unexpected emissions in low-speed applications due to the high frequency components of fast edges. To smooth the bus signal, differential capacitor can be added on the bus to form a low pass filter.

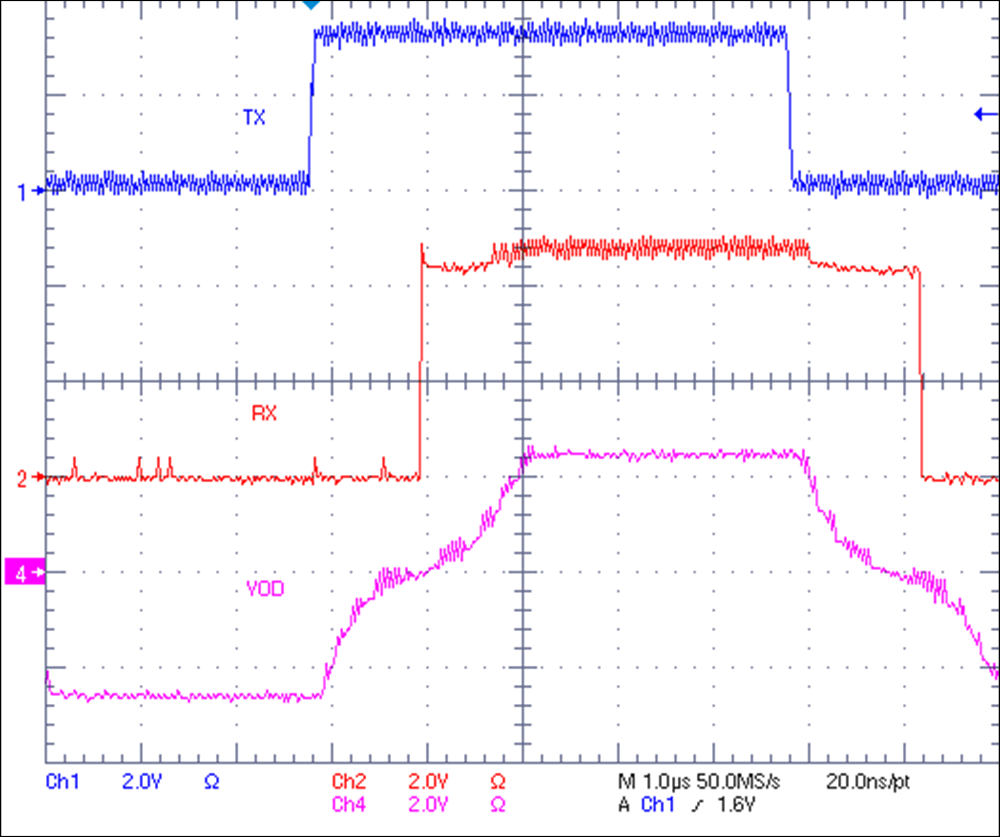

For comparison, SN65HVD1780 is chosen as the benchmark. This device also has high fault voltage (±70-V) protection, while working with low data rates – up to 115-kbps. With 5-V Vcc and 120-Ω termination resistor, Figure 2-4 shows the SN65HVD1780 bus pin output with a 100kHz clock input. The differential bus signal (channel 4) shows about 2-μs rise and or fall time, which aligns with the data sheet specification.

Figure 2-4 SN65HVD1780 Rise and or Fall

Time

Figure 2-4 SN65HVD1780 Rise and or Fall

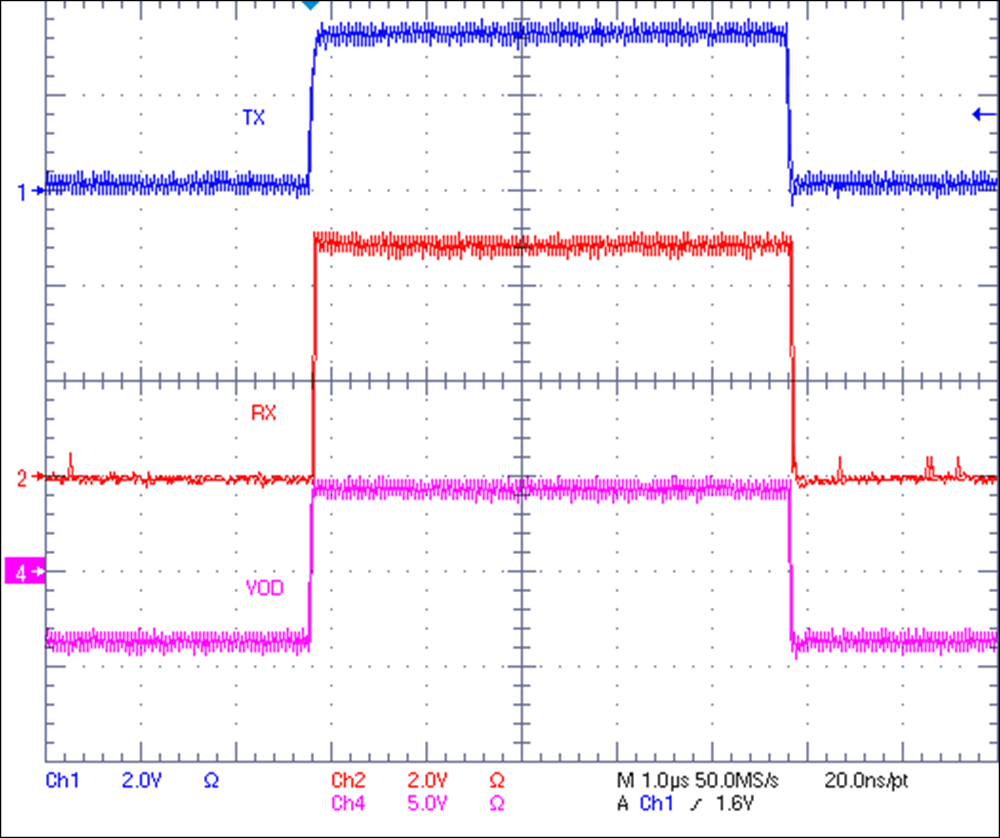

TimeWhile using the same set up as the SN65HVD1780 used, THVD2540 results in sharp edges which are expected since the device has 5 ns rise and or fall time (Figure 2-5).

Figure 2-5 THVD2450 Rise and or Fall

Time

Figure 2-5 THVD2450 Rise and or Fall

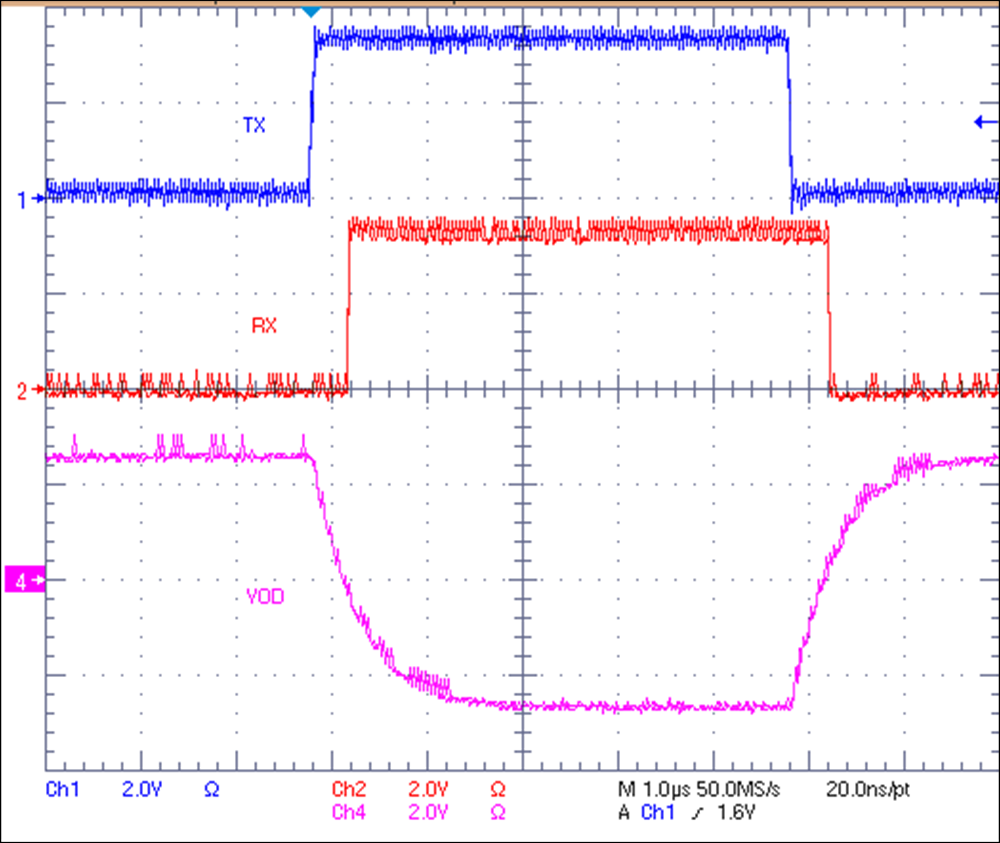

TimePopulating a differential capacitor can effectively slow down fast edges on the THVD2540. The capacitor is parallel to the termination resistor, while two components can be placed side by side on the board, like Figure 2-6.

Figure 2-7 is the results of THVD2450 with an extra 8200-pF differential capacitor placed on the bus, while the other test setup is the same as before. THVD2450’s driver takes time to charge and discharge the large capacitor, making the fast edges rounded. With the 8200-pF capacitor, the rise/fall time is now longer than 1-μs, which is very close to that of SN65HVD1780 in Figure 2-4. This experiment shows that the high-speed devices can be used in low-speed applications, while adding a differential capacitor can effectively mitigate electromagnetic interference (EMI) concerns.

Figure 2-7 THVD2450 Rise and or Fall Time

With 8200-pF Capacitive Load

Figure 2-7 THVD2450 Rise and or Fall Time

With 8200-pF Capacitive Load